Underground gasification furnace

A technology of underground gasification and gasification channels, which is applied in the direction of coal gasification, underground mining, mining fluids, etc., can solve the problems of poor oblique impact force and increased cementing cost, and achieve the goal of reducing impact, deformation or damage effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described below with reference to the drawings.

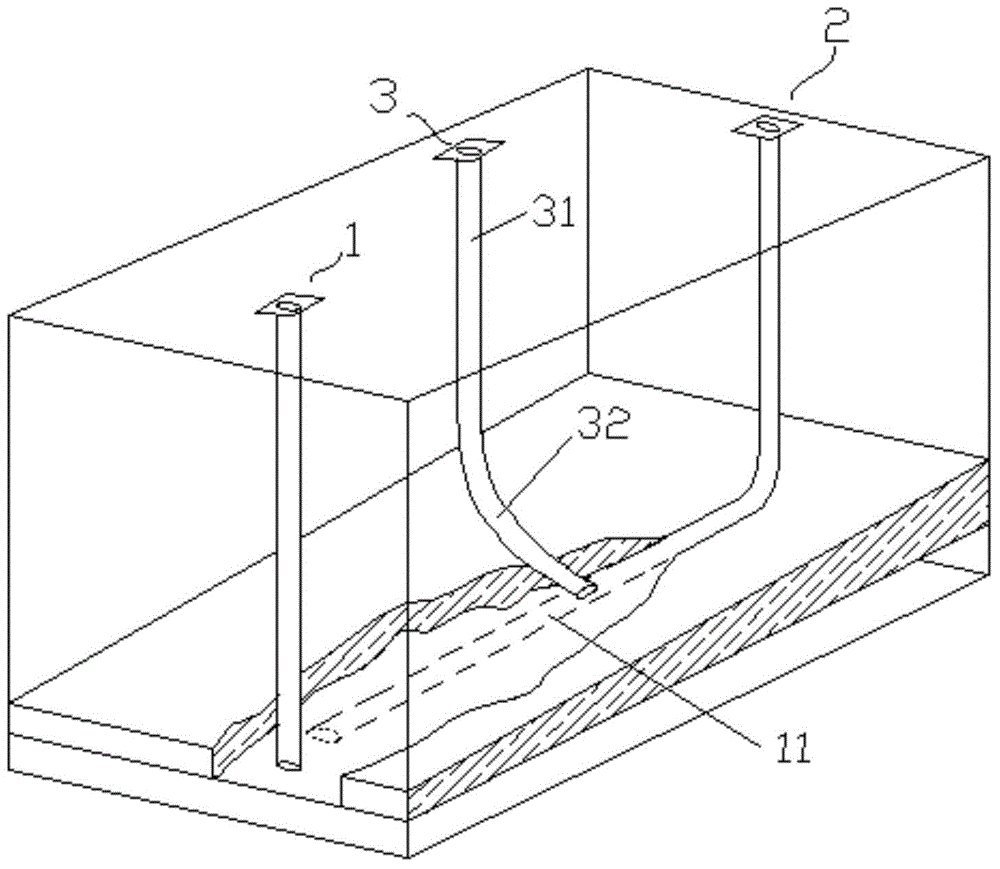

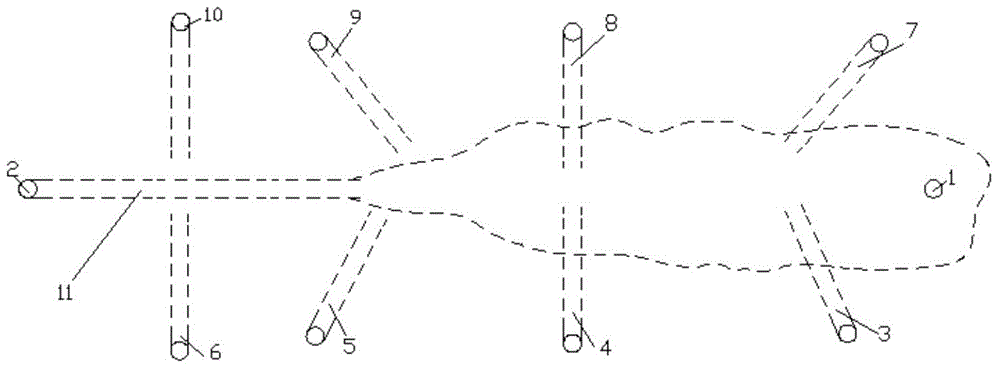

[0021] refer to figure 1 and figure 2 , an embodiment of the underground gasification furnace of the present invention, comprising a gasification channel 11 and at least one process well provided with a cementing casing, the process well is located on one side of the gasification channel and includes a manufacturing well extending toward the gasification channel 11 The deviated well section 32, the bottom of the deflected well section 32 constitutes the bottom of the process well. Wherein, the gasification channel 11 is located in the coal seam. In the projection of the process well and the gasification channel on the horizontal plane, the projection of the process well is located on one side of the projection of the gasification channel, that is, the process well is located on one side of the gasification channel. The horizontal plane mentioned in this embodiment is a plane p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com