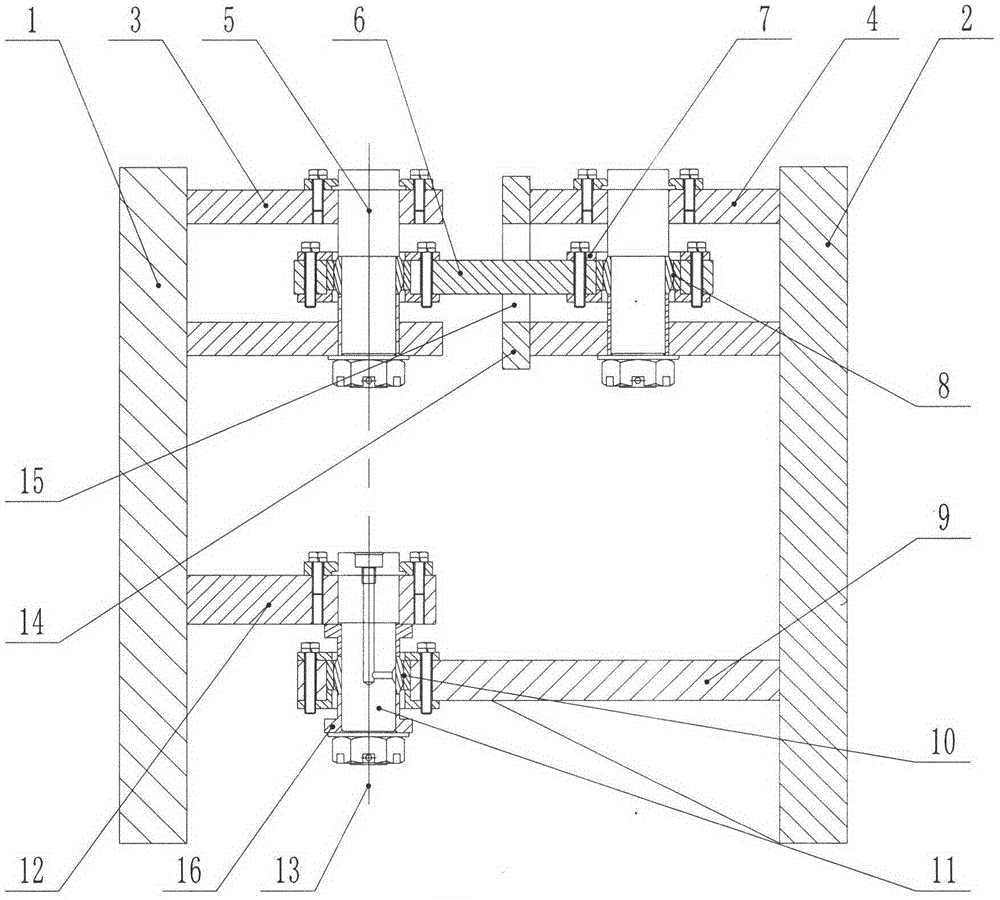

Front-rear-rack hinge-connecting device for small-sized wheel type loading machine

A wheel loader and connecting device technology, which is applied in traction connectors, earth movers/excavators, transportation and packaging, etc., can solve the problems of high processing and assembly precision, failure of hinge joints, and difficulty in adjustment, etc. Achieve the effects of low machining accuracy requirements, guaranteed reliability, and simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

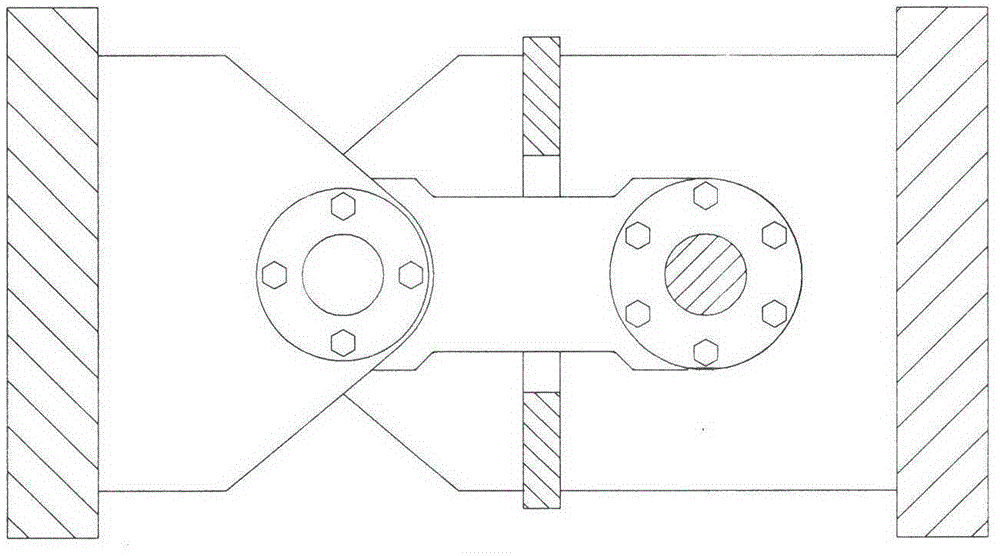

[0007] The structure and use of the present invention will be described in detail below in conjunction with the embodiments given in the accompanying drawings. Referring to the accompanying drawings, this kind of small wheel loader front and rear frame hinge connection device has a front frame (1) and a rear frame (2), and a group of pin plates (3) on the front frame are provided on the front frame. There is a group of pin plates (4) on the rear frame on the rear frame, pin holes are arranged on the pin plate on the front frame and the pin plate on the rear frame, and upper pin shafts (5) are respectively assembled, and it is characterized in that The middle position of the two upper bearing pins is assembled with hinged connecting rods (6) through the upper joint bearings (8); there is a front vehicle frame lower pin fixed pulley (12) at the bottom of the front vehicle frame, and at the bottom of the rear vehicle frame There is a hinged fixed plate (9) under the rear vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com