Bridge deck unit without transverse surface tension joints, bridge structure and its construction method

A bridge structure, no lateral technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of cracking, large lateral joints, affecting the durability of bridge decks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

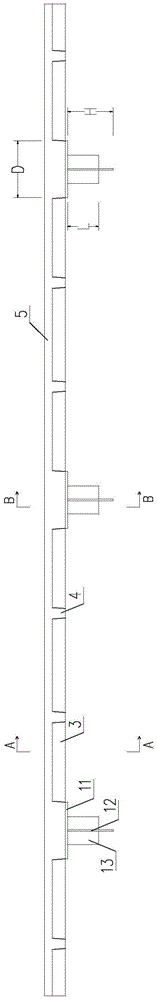

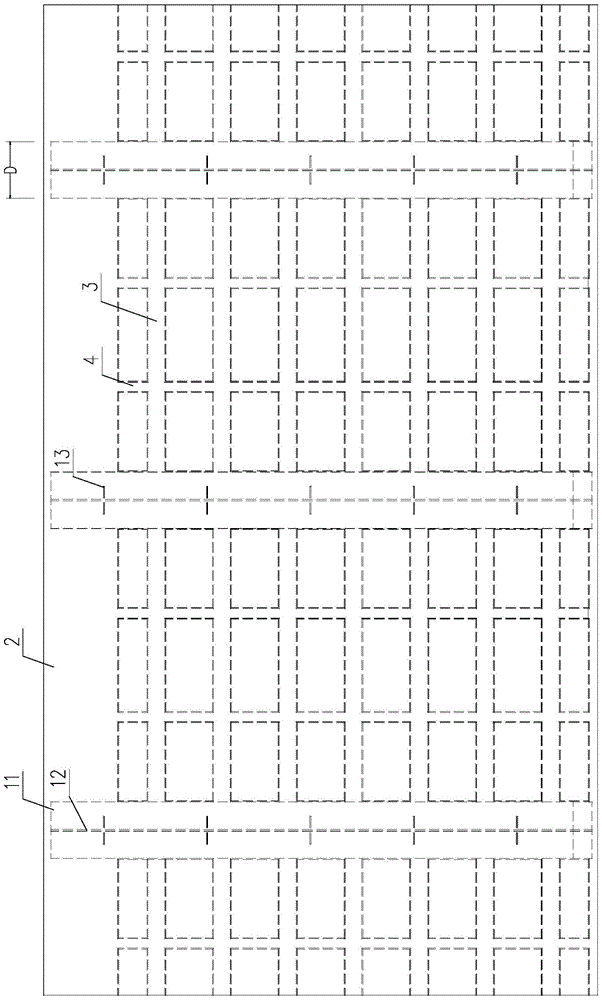

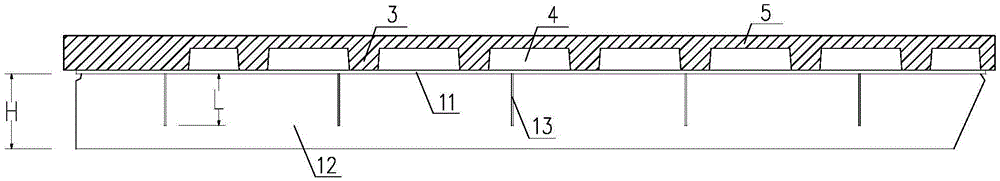

[0045] Such as Figure 1 to Figure 4 Shown, a bridge deck unit without transverse surface tension joints applicable to steel-ultra-high performance concrete composite structure of the present invention, the bridge deck unit mainly consists of diaphragm 1 of steel material and ultra-high performance concrete material The bridge deck 2 is integrally prefabricated; the diaphragm 1 includes an upper flange 11 and an upper web 12 fixed to each other. Such as figure 1 As shown, the upper flange 11 of the diaphragm 1 is pre-embedded in the bridge deck 2, and there is no transverse surface tension joint above the upper flange 11; the upper web 12 of the diaphragm 1 is arranged at intervals along the transverse direction of the bridge There are multiple upper vertical stiffeners 13 parallel to each other (see figure 1 with figure 2 ). The bridge deck 2 adopts a grid-like thin plate with longitudinal ribs 3 and transverse ribs 4 on the lower part (see figure 2 ). Both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com