Waterborne environment-friendly direct-plating beer bottle label base and surface paint with ink retaining performance

An environmentally friendly, beer-labeled technology, applied in paper coating, coating, fiber raw material treatment, etc., to achieve excellent ink retention effect, excellent ink adhesion, and low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a preparation method of a water-based environment-friendly direct-plating beer label bottom coating that can allow ink to reside. In this method, the preparation of the bottom coating component includes the following steps:

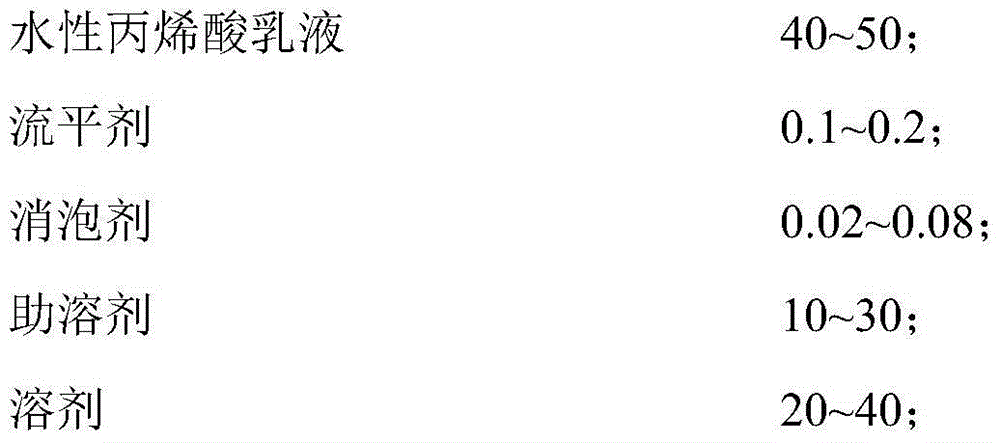

[0029] 1. Prepare materials according to the formula in Table 1;

[0030] 2. Put the solvent into the reaction kettle, turn on the mixer to a medium speed of 700-800 rpm, add the water-based acrylic emulsion into the reactor, and stir at 700-800 rpm for 60 minutes until the mixture is uniform;

[0031] 3. Add co-solvent at a speed of 1000-1200 rpm, and stir until evenly mixed;

[0032] 4. Add leveling agent to the reaction kettle, and stir at a medium speed of 700-800 rpm for 10-20 minutes;

[0033] 5. Add defoamer to the reaction kettle, and stir at a high speed of 1000-1200 rpm for 10-20 minutes to obtain the primer component.

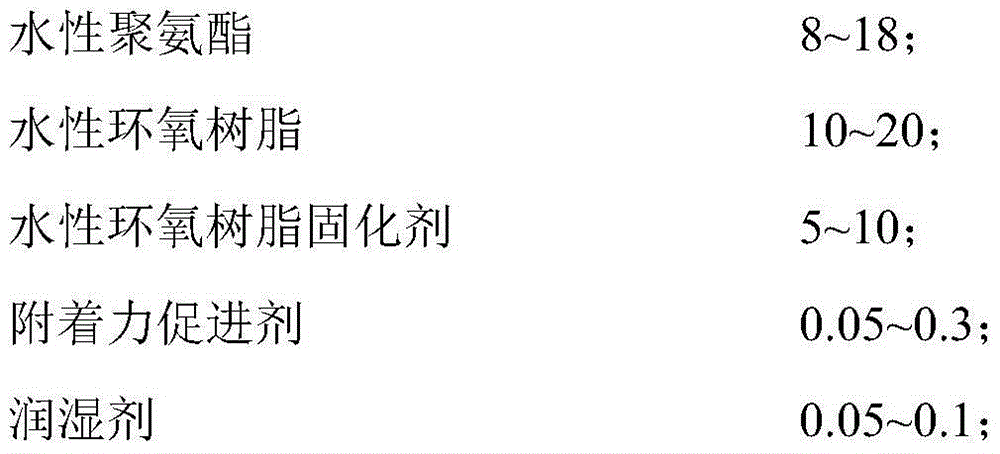

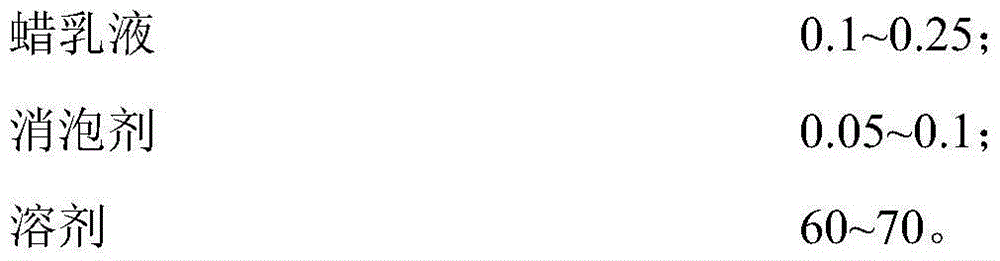

[0034] The preparation of surface coating component comprises the steps in the method:

...

Embodiment 2

[0041] Its formula is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0043] Its formula is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com