Czochralski crystal growth furnace

A technology of crystal growth furnace and pulling method, which is applied in the directions of crystal growth, single crystal growth, and self-melting liquid pulling method, etc. It can solve the problems of unstable cooling gas and the accumulation of impurities in inclusions in the melt, and achieve the suppression of natural The effect of convection intensity, reduction of inclusion impurities, and avoidance of excessive thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

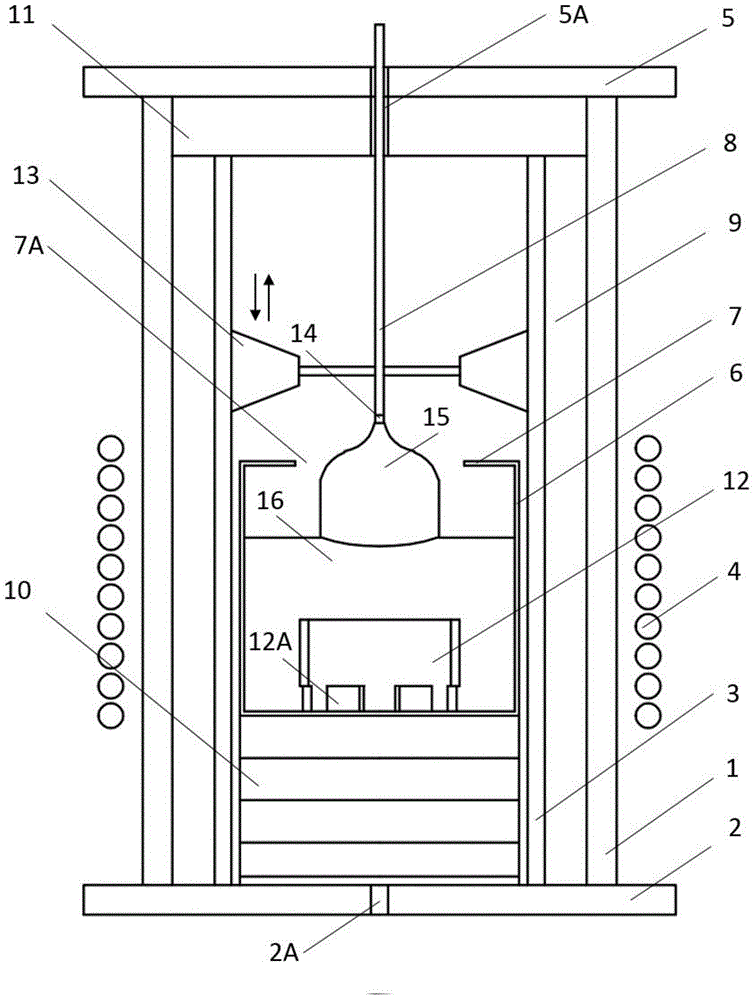

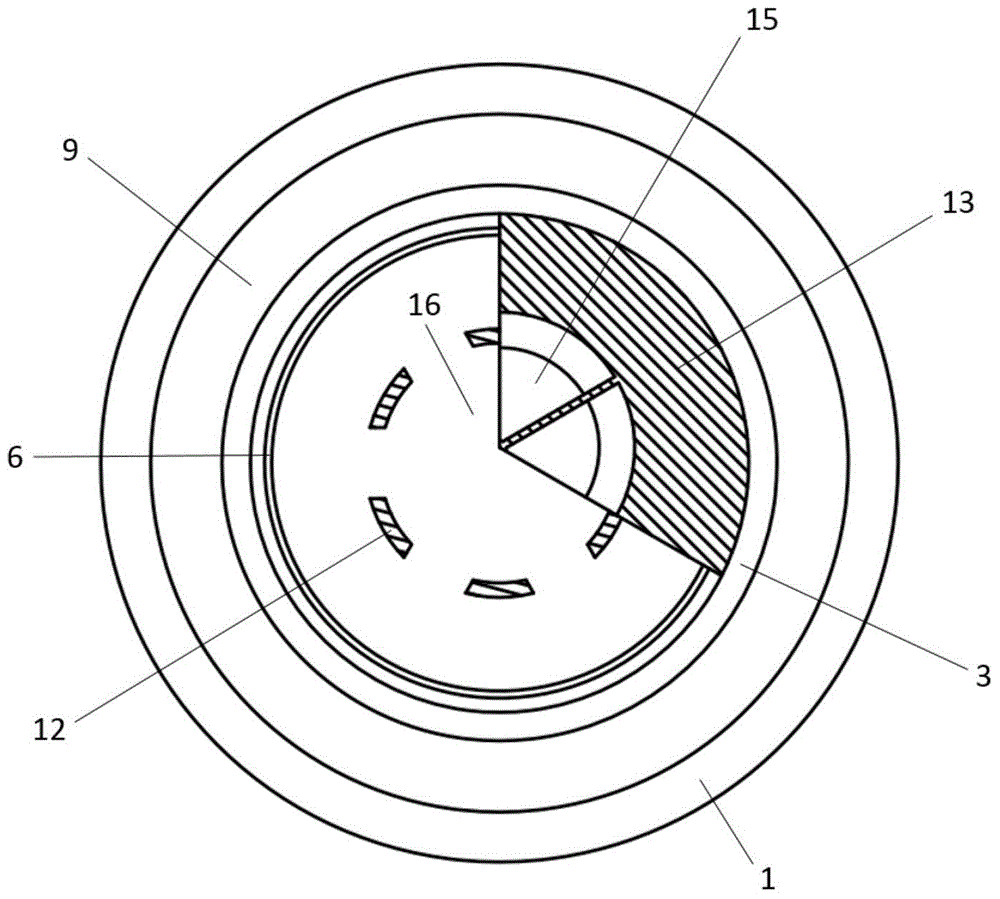

[0021] Such as figure 1 As shown, the present invention includes a furnace body 1, a base 2, an inner insulation layer 3, an electromagnetic induction heater 4, a furnace cover 5, a crucible 6, a crucible cover 7 and a seed rod 8;

[0022] The furnace body 1 is a cylinder, the base 2 is fixedly connected to the bottom of the furnace body 1 and closed, the center of the base has an air inlet channel 2A, and the inner heat insulation layer 3 is also a cylinder, It is located on the base 2 of the furnace body and forms a coaxial sandwich structure with the furnace body. The annular cavity between the furnace body and the inner heat insulation layer is filled with side wall heat insulation material 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com