Oil well casing cathodic protection system and electrode layout method based on pulse current

An oil well casing and pulse current technology, which is applied in the field of oil well casing cathodic protection system and electrode layout based on pulse current, can solve the problems of deepening oil well casing protection depth, affecting the life of anode system, long transmission distance of pulse current, etc. problems, to extend the depth of protection, improve anode utilization and efficiency, and reduce the effect of IR drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and the examples given by the inventor.

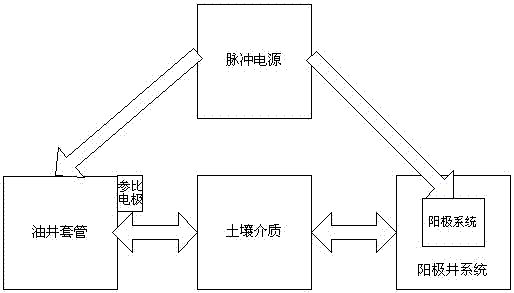

[0027] see figure 1 , the cathodic protection system for oil well casing based on pulse current, including a pulse power supply connected to the oil well casing 8 and the anode well system respectively; a soil medium is arranged between the oil well casing and the anode well system. The oil well casing is also connected with the reference electrode.

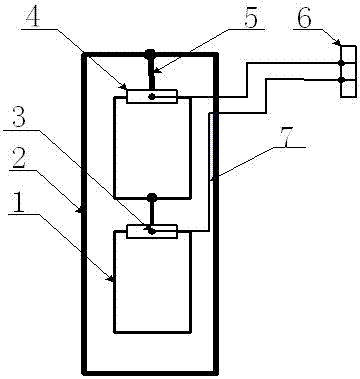

[0028] see figure 2 , the anode well system includes an anode 1, the anode 1 is located in the anode well 2, the anode 1 is connected to the sealing joint 4 and the cable 7 through the anode cable connection point 3 respectively; the sealing joint 4 is respectively connected to the anode support structure 5, the whole The type buried joint 6 is connected; the anode cable connection point 3 is connected with the integral buried joint 6 through the cable 7.

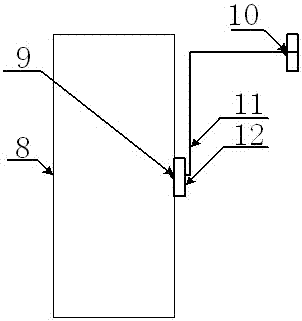

[0029] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com