Molten iron for casting pressure plate castings and casting method for pressure plate castings

A pressure plate and molten iron technology, applied in the field of casting, can solve the problems of shrinkage and porosity at hot joints and high production defect rate, and achieve the effect of reducing production defect rate and eliminating shrinkage and porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

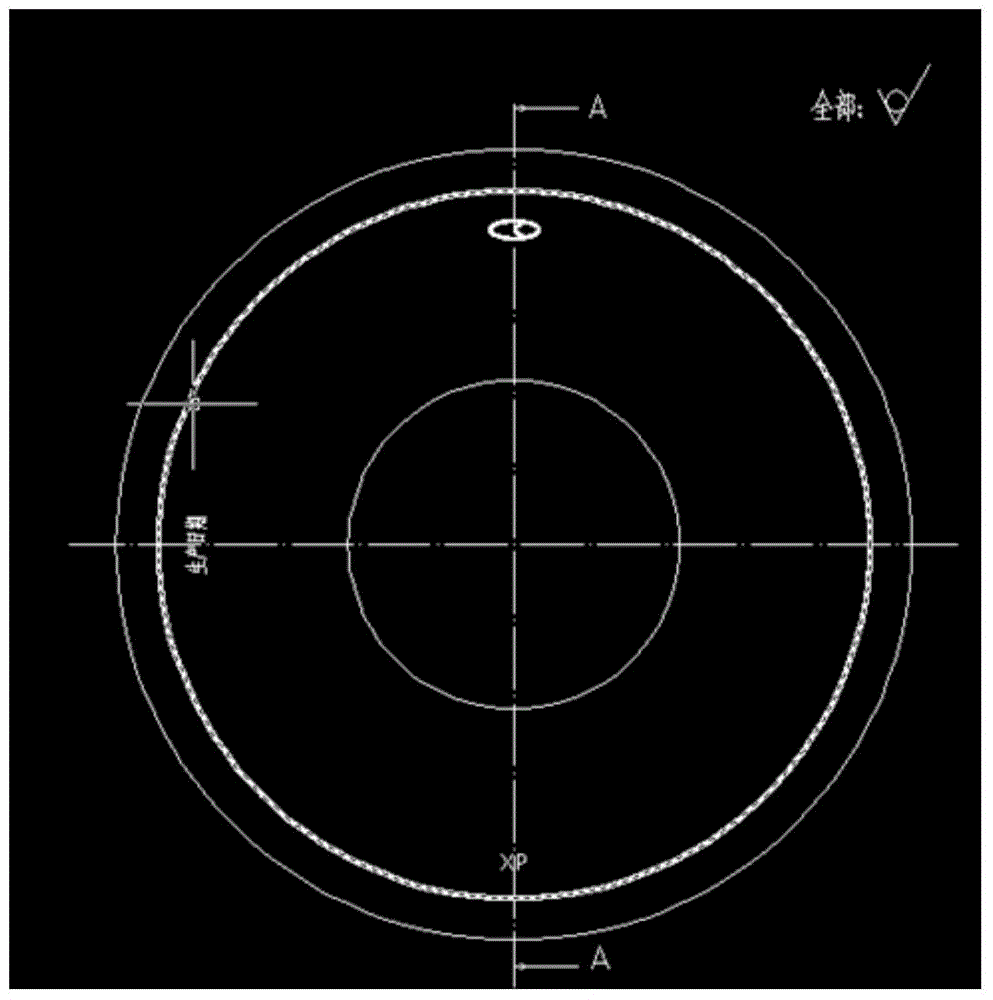

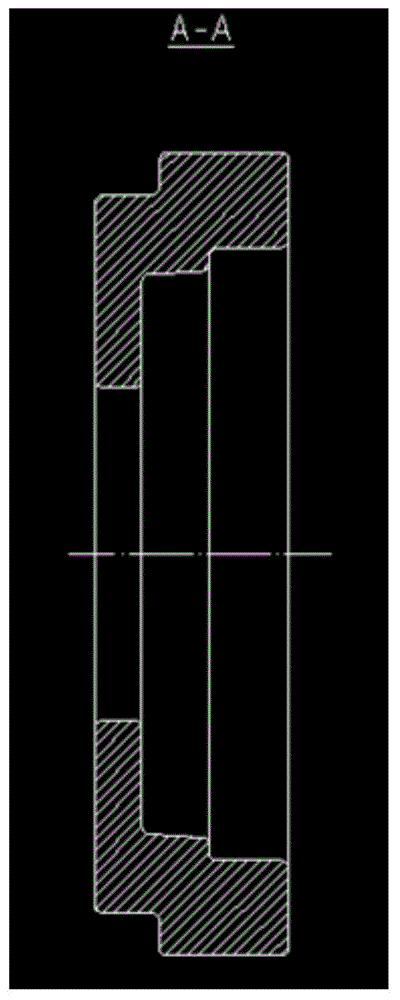

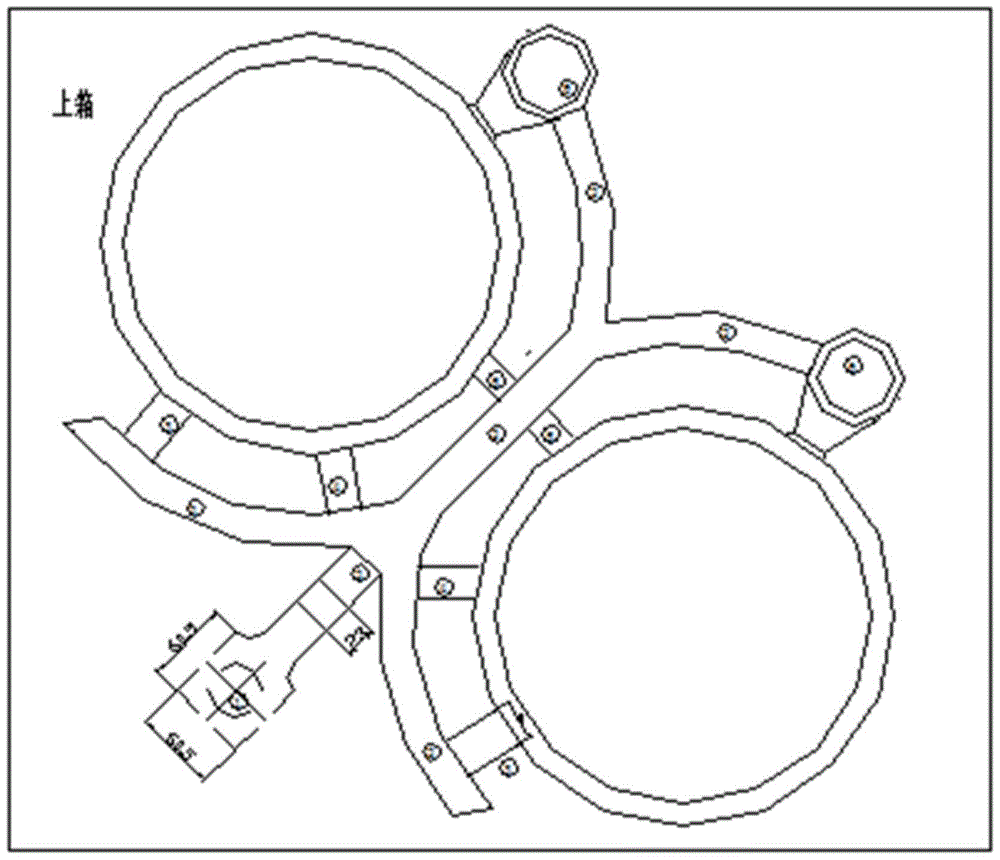

[0115] according to Figure 1 to Figure 4Put the upper and lower mold templates of the pressure plate product into the template frame respectively for fastening, after fastening, hang the template frame into the upper and lower template frame positioning sleeves of the two-station molding machine , spray the parting liquid, adjust the compaction force of the molding machine to 0.6MPa, and adjust the excavation position of the sprue cup, and then start the molding. After the mold is built, the interior of the cavity is inspected, and the mold is closed and waits for pouring.

[0116] Add 600kg of pig iron, 900kg of scrap steel and 1500kg of returned materials into a 3-ton medium-frequency induction furnace for smelting. When all of them are melted, slag removal is carried out, and the temperature is raised to 1450°C, and then 75% of ferrosilicon, ferromanganese, copper, soldering iron and tin particles are added for smelting. Adjustment, after the chemical composition of the ad...

Embodiment 2

[0128] The molding process of this embodiment is the same as that of Embodiment 1.

[0129] Add 600kg of pig iron, 900kg of scrap steel and 1500kg of returned material to a 3-ton medium-frequency induction furnace for smelting. When all of them are melted, slag removal is carried out, and the temperature is raised to 1400°C, and then 75% of ferrosilicon, ferromanganese, copper, soldering iron and tin particles are added for smelting. Adjustment, after the chemical composition of the adjusted molten iron meets the requirements of the control standard, the temperature is raised to 1530 ° C, and the chemical composition other than the iron element is obtained as shown in Table 6. Table 6 is the main composition of the molten iron used in Example 2. chemical composition.

[0130] When 600kg±10kg appears on the molten iron weighing display screen, use a forklift to transport the transfer bag containing the molten iron to the pouring section, pour 2.4kg of inoculant into the ladle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com