A method for separating and extracting valuable components of boron-magnesium-iron symbiotic ore

A technology of symbiotic minerals and boron-magnesium iron, applied in the direction of improving process efficiency, etc., can solve the problems of waste of resources, unrealized comprehensive utilization, and many symbiotic minerals, and achieve high recovery rate, comprehensive utilization of resources, environmental friendliness, and high-efficiency separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

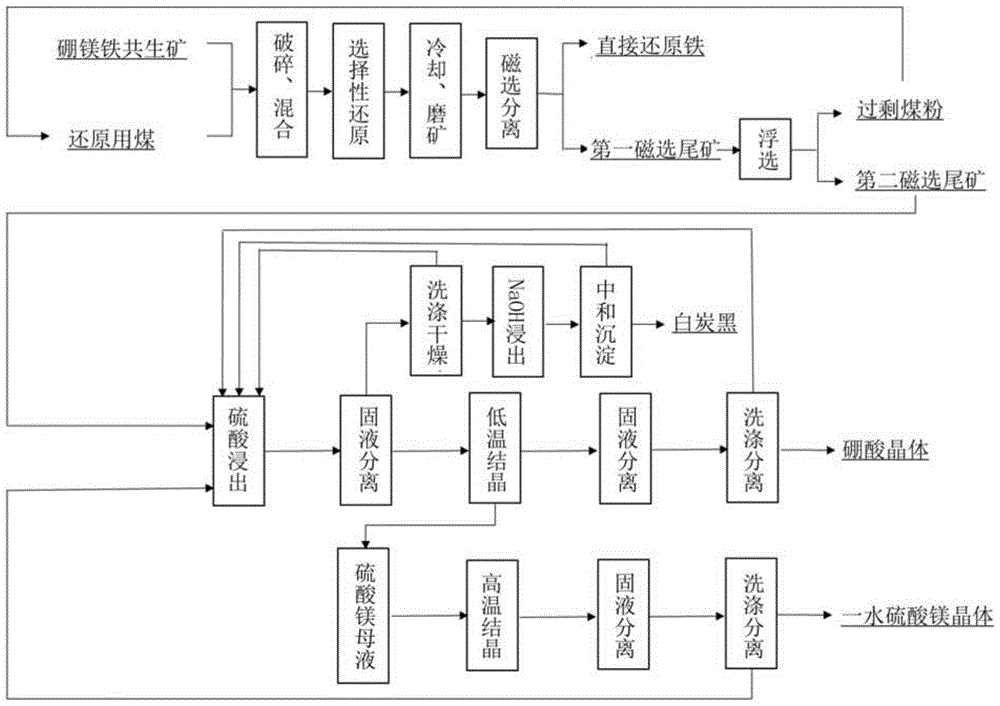

Method used

Image

Examples

Embodiment 1

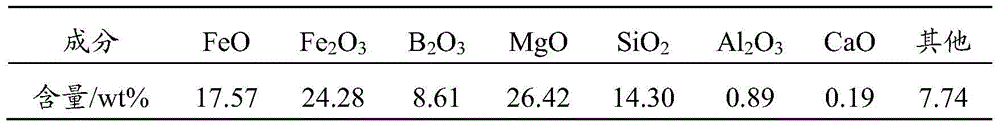

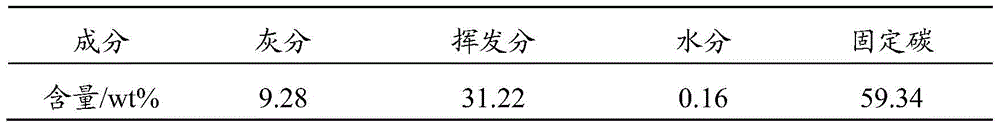

[0053] Example 1 The boron-magnesium-iron symbiotic ore in a certain area of Dandong was used as raw material, and the coal used for reduction was bituminous coal.

[0054] Table 1 Main components of boron-magnesium-iron symbiotic ore

[0055]

[0056] Table 2 Industrial analysis of bituminous coal

[0057]

[0058] The separation and extraction steps are as follows:

[0059] (1) The boron-magnesium-iron symbiotic ore is crushed into a maximum particle size of 3.15mm by a jaw crusher, and the pulverized coal is pulverized into a maximum particle size of 3.15mm by a pulverizer;

[0060] (2) Mix boron-magnesium-iron symbiotic ore and coal powder evenly in a mass ratio of 100:25 to make a mixture;

[0061] (3) Spread a layer of coke powder with a thickness of 3mm on the bottom of the reduction furnace, and then spread the mixture on the coke powder for selective reduction. The thickness of the mixture is 30mm, and the surface of the mixture is covered with a layer of 3mm....

Embodiment 2

[0071] Raw materials such as boron-magnesium-iron symbiotic ore, reducing coal, sulfuric acid and caustic soda in Example 1 were used.

[0072] The separation and extraction steps are as follows:

[0073] (1) The boron-magnesium-iron symbiotic ore is crushed into a maximum particle size of 10mm by a jaw crusher, and the pulverized coal is pulverized into a maximum particle size of 2mm by a pulverizer;

[0074] (2) Mix boron-magnesium-iron symbiotic mineral powder and coal powder uniformly in a mass ratio of 100:15 to make a mixture;

[0075] (3) Spread a layer of coke powder with a thickness of 3mm on the bottom of the reduction furnace, and then spread the mixture on the coke powder for selective reduction. The thickness of the mixture is 30mm, and the surface of the mixture is covered with a layer of 3mm. For protective pulverized coal, the selective reduction temperature is 1225°C and the time is 75 minutes;

[0076] (4) After reduction, the reducing material is taken out...

Embodiment 3

[0085] Raw materials such as boron-magnesium-iron symbiotic ore, reducing coal, sulfuric acid and caustic soda in Example 1 were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com