Method and equipment for extracting soybean oil under help of composite enzyme membrane

A technology of auxiliary extraction and composite enzyme membrane, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of reduced cake efficiency, long oil extraction time, large enzyme consumption, etc., and achieves low maintenance and operation costs and easy automation Good control and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

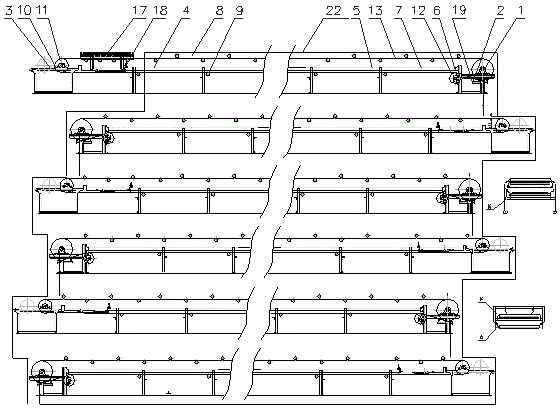

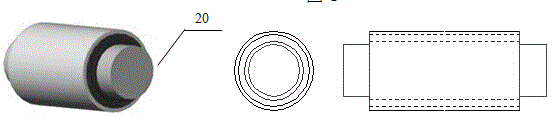

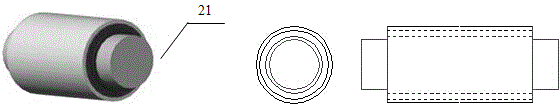

[0008] Specific implementation mode one: as figure 1 As shown, this embodiment includes a motorized drum (1), a belt (13), a parallel upper roller (8), a parallel lower roller (9) and a material guide groove (17), and it is characterized in that it also includes immobilized fibers Suzyme roller (20), immobilized alkaline protease roller (21) and vacuum container (22), the electric drum (1) is supported by the head frame (2) and drives the belt (13) at a speed of 0.03m / s Rotate, the lower end of the electric drum (1) communicates with the spring cleaner (19);

[0009] The left end of the belt (13) is connected to the reversing roller (11), the right end of the belt (13) is connected to the reversing roller (12), and the upper part of the belt (13) is parallel to the idler roller (8) Support, the lower part of the belt (13) is supported by a parallel lower idler roller (9), the upper left end of the belt (13) is equipped with a guide groove (17), and the lower left end of the b...

specific Embodiment approach 2

[0015] Specific implementation mode two: as figure 1 As shown, the difference between the present embodiment and the first embodiment is that it designs two layers of conveying devices to ensure that the enzyme roller is in full contact with the soybean embryo sheet, and the distance between each layer of conveying devices is 1750mm.

specific Embodiment approach 3

[0016] Specific implementation mode three: as figure 1 As shown, the difference between the present embodiment and the first embodiment is that the immobilized cellulase rollers (20) and the immobilized alkaline protease rollers (21) are placed crosswise, and the distance between them is 200 mm.

[0017] Specific implementation mode four: as figure 1 As shown, the action time of the immobilized cellulase roller ( 20 ) in the first embodiment and the soybean embryo flakes is 30 minutes, and the action time of the immobilized cellulase roller ( 21 ) and the soybean embryo flakes is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com