A conical bottom tank for oil sand treatment

A technology for conical bottom tanks and oil sands, applied in the petroleum industry, production fluids, boreholes/well components, etc., can solve the problem of reducing the overall safety of conical bottom tanks, large changes in structural shape and size, and affecting the working efficiency of conical bottom tanks and other problems, to achieve the effect of increasing the effective working volume, making the production simple and increasing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

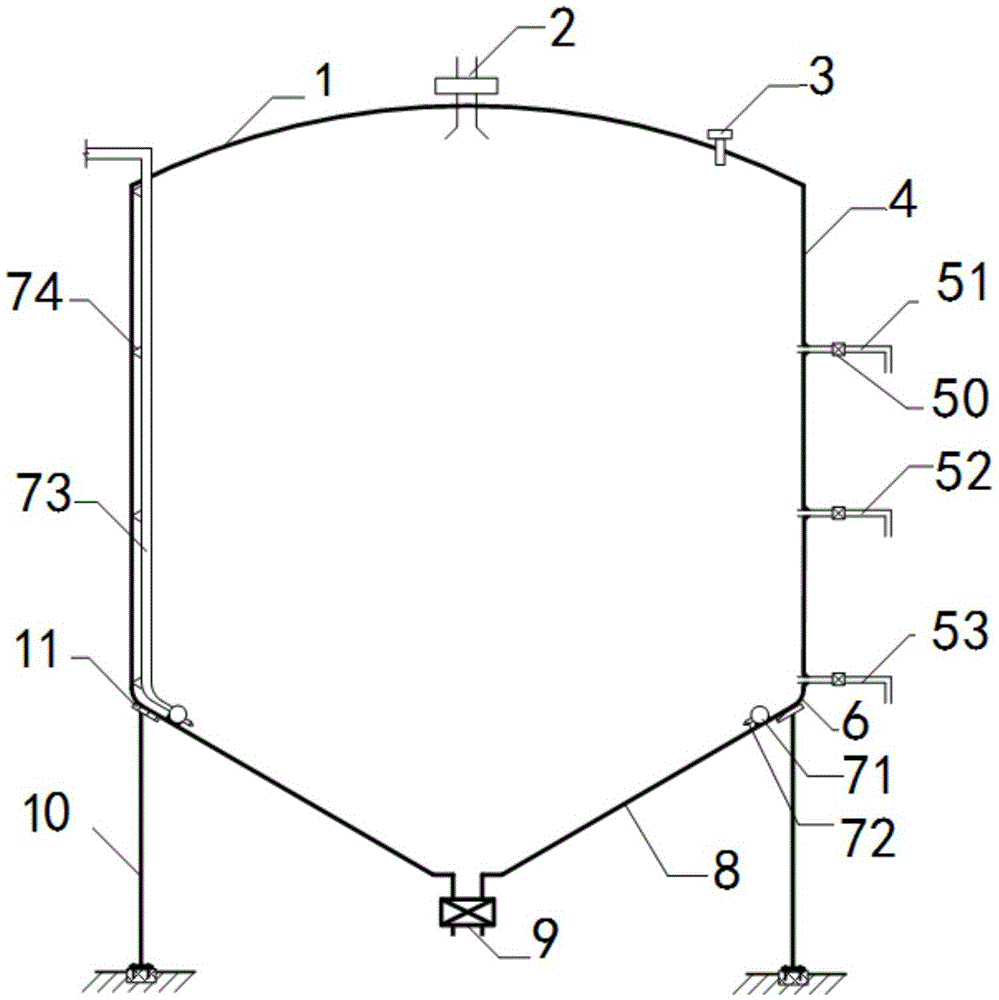

[0026] Embodiment 1: as figure 1 , figure 2 As shown, a conical bottom tank for oil sand treatment,

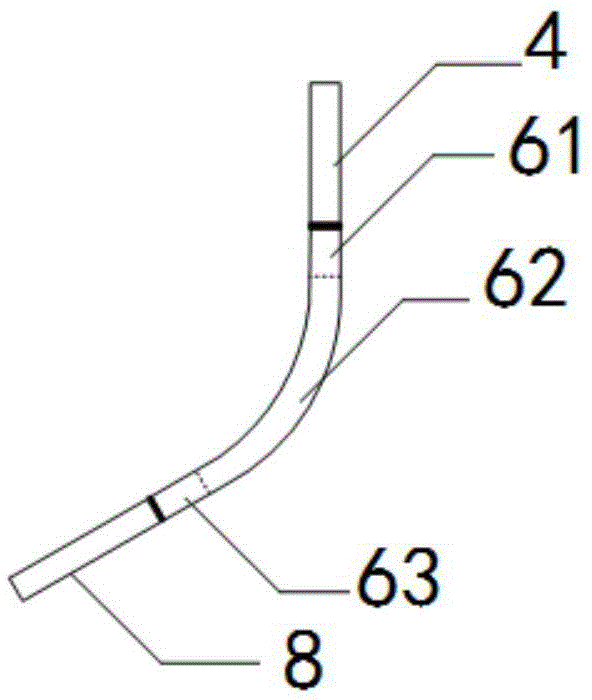

[0027] In the figure: 1, tank top, 2, oil sand inlet, 3, pressure balance valve, 4, tank wall, 50, throttle valve, 51, upper liquid discharge pipe, 52, middle liquid discharge pipe, 53, lower Drain pipe, 6, arc-shaped cone bottom plate, 61, upper straight plate section, 62, circular arc section, 63, lower straight plate section, 71, ring pipe, 72, nozzle, 73, high-pressure water pipe, 74, pipe clamp, 8 , Straight cone bottom plate, 9, oil sand outlet, 10, support system, 11, reinforcing plate.

[0028] Such as figure 1 As shown, the conical bottom tank for oil sand treatment includes: a tank top 1, a tank wall 4, and a straight conical bottom plate 8, the top of the tank wall 4 is connected to the tank top 1, and the bottom end of the tank wall 4 passes through an arc-shaped conical bottom plate 6 It is connected with the top of the straight cone bottom plate 8, and the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com