Method of producing ethanolamine from liquid ammonia

A technology of ethanolamine and liquid ammonia, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of many by-products, high equipment investment, low safety, etc., and achieve product purity and easy separation , the reaction temperature is controllable, and the effect of avoiding safety accidents and equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

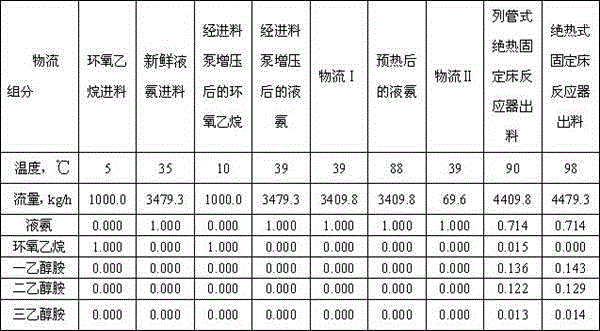

Embodiment 1

[0023] Ethylene oxide and fresh liquid ammonia enter the tube-and-tube fixed-bed reactor through the feed pump respectively, and the reaction products enter the adiabatic fixed-bed reactor. Both the tube-and-tube fixed-bed reactor and the adiabatic fixed-bed reactor are filled with Binder ZSM-5 zeolite molecular sieve catalyst.

[0024] Fresh liquid ammonia is divided into stream Ⅰ and stream Ⅱ. Stream Ⅰ enters the tubular fixed-bed reactor after being preheated and mixed with ethylene oxide, and stream Ⅱ directly enters the adiabatic fixed-bed reactor. In the shell-and-tube fixed-bed reactor, the circulating hot water in the shell side and the reaction materials in the tube side flow in the same direction, and the heat of reaction is continuously withdrawn. The circulating hot water exits the tubular fixed-bed reactor and passes through the circulation pump to exchange heat with stream I, and then enters the tubular fixed-bed reactor after being cooled by the cooler.

[0025...

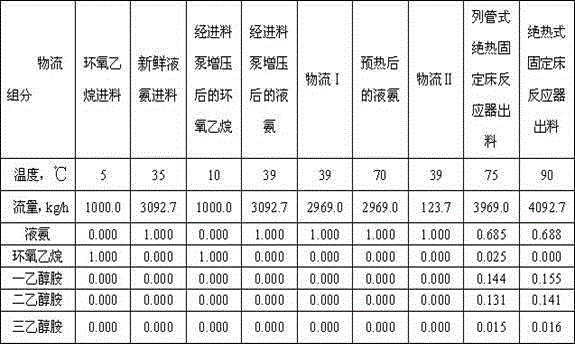

Embodiment 2

[0034] Ethylene oxide and fresh liquid ammonia enter the tube-and-tube fixed-bed reactor through the feed pump respectively, and the reaction products enter the adiabatic fixed-bed reactor. Both the tube-and-tube fixed-bed reactor and the adiabatic fixed-bed reactor are filled with Binder ZSM-5 zeolite molecular sieve catalyst.

[0035] Fresh liquid ammonia is divided into stream Ⅰ and stream Ⅱ. Stream Ⅰ enters the tubular fixed-bed reactor after being preheated and mixed with ethylene oxide, and stream Ⅱ directly enters the adiabatic fixed-bed reactor. In the shell-and-tube fixed-bed reactor, the circulating hot water in the shell side and the reaction materials in the tube side flow in the same direction, and the heat of reaction is continuously withdrawn. The circulating hot water exits the tubular fixed-bed reactor and passes through the circulation pump to exchange heat with stream I, and then enters the tubular fixed-bed reactor after being cooled by the cooler.

[0036...

Embodiment 3

[0045] Ethylene oxide and fresh liquid ammonia enter the tube-and-tube fixed-bed reactor through the feed pump respectively, and the reaction products enter the adiabatic fixed-bed reactor. Both the tube-and-tube fixed-bed reactor and the adiabatic fixed-bed reactor are filled with Binder ZSM-5 zeolite molecular sieve catalyst.

[0046] Fresh liquid ammonia is divided into stream Ⅰ and stream Ⅱ. Stream Ⅰ enters the tubular fixed-bed reactor after being preheated and mixed with ethylene oxide, and stream Ⅱ directly enters the adiabatic fixed-bed reactor. In the shell-and-tube fixed-bed reactor, the circulating hot water in the shell side and the reaction materials in the tube side flow in the same direction, and the heat of reaction is continuously withdrawn. The circulating hot water exits the tubular fixed-bed reactor and passes through the circulation pump to exchange heat with stream I, and then enters the tubular fixed-bed reactor after being cooled by the cooler.

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com