System and method for detecting smoothness of track

A smoothness and track technology, which is applied in the field of systems for detecting track smoothness, and can solve problems such as affecting data accuracy and causing great damage to human eyes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions are preferred implementation examples of the present invention, which do not limit the protection scope of the present invention.

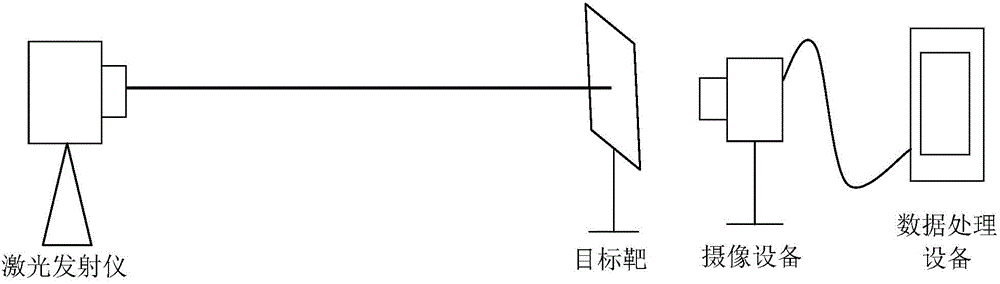

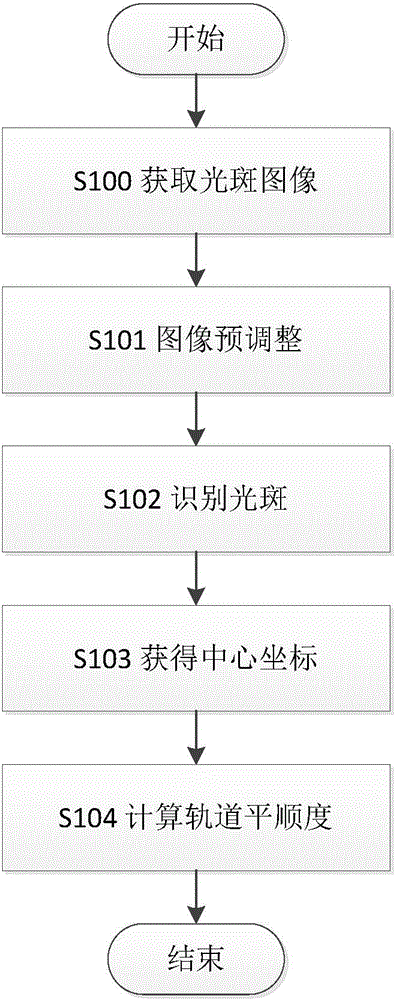

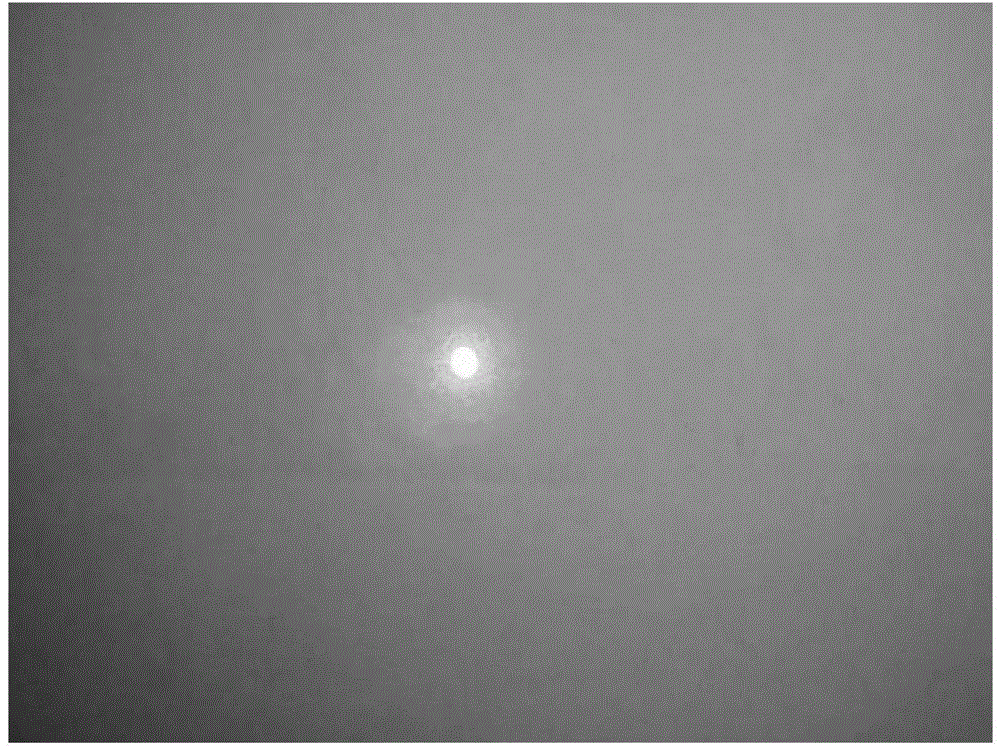

[0033] Such as figure 1 As shown, the system for detecting smoothness of the track proposed by the present invention includes a laser transmitter, a target, an imaging device, and a data processing device. Wherein, the target surface of the target is made of translucent material, and the center horizontal line of the camera head of the imaging device located behind the target is facing the center of the target surface. When the laser of the laser emitter located in front of the target is turned on, the light is projected onto the target surface to form a spot. Since the target is made of translucent material, the projection of the light spot can be clearly seen on the side of the camera behind the target. The camera of the imaging device captures the image formed by the light spots. The data processing device c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com