Preparation method of heat insulation pad and heat insulation pad prepared thereby

A technology of thermal insulation pad and adhesive is applied in the preparation of thermal insulation pad and the field of thermal insulation pad, which can solve the problems of poor mechanical properties and poor thermal insulation performance, and achieve the effects of good performance, good thermal insulation properties and simple operation.

Inactive Publication Date: 2015-04-29

AVIC GUIZHOU AIRPLANE

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the technical problems of poor thermal insulation performance and poor mechanical properties in the prior art, the present invention provides a method for preparing a thermal insulation pad with low production cost, satisfactory mechanical properties, and can be processed into a curved surface and using the Insulation mat made by method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

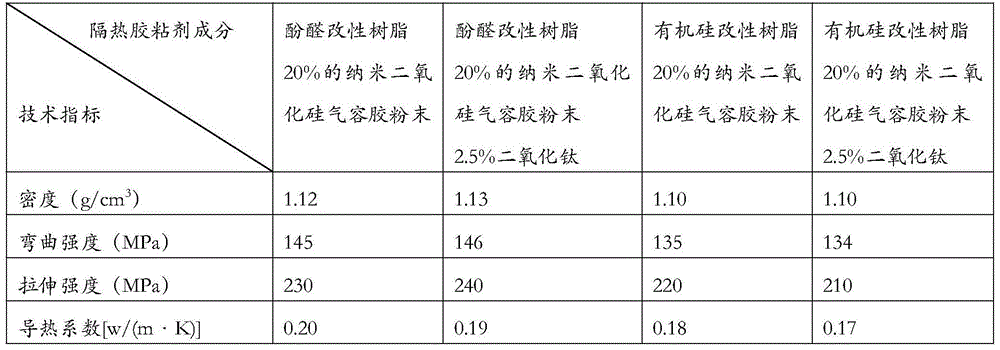

[0016] In the preparation method disclosed in the present invention, different heat-insulating adhesive components have the greatest influence on various indexes. Therefore, the present invention prepares The thermal insulation pad is tested for various technical indicators, and the test data are as follows:

[0017] The technical indicators measured by the test are: density, bending strength, tensile strength, and thermal conductivity.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A preparation method of a heat insulation pad relates to the field of composite material and comprises the following steps: a, blending a heat insulation adhesive; b, brushing with the heat insulation adhesive to prepare woolen fabrics; c, laying and folding the woolen fabrics; and d, carrying out compression molding. According to the heat insulation pad prepared by the method, ceramic fiber or glass fiber fabrics are used as carriers, each piece of carrier is brushed with the adhesive for multiple times to be used as the woolen fabric; the adhesive is formed by adding a nano silica aerosol powder with the mass 10-30% that of modified resin into the modified resin and then mixing evenly, and the control amount of the adhesive is 500-900 g / m<2>; the heat insulation pad is formed by laying and folding multiple layers of woolen fabrics and then carrying out compression molding. The produced heat insulation pad has a better heat insulation characteristic, and besides, also can provide good bending strength, tensile strength and compressive strength for a heat insulation system; the preparation method is simple to operate; and the heat insulation pad is good in performance and low in cost, fills a research and development blank in the domestic heat insulation field, and can be widely applied to the heat insulation system in high temperature environments.

Description

technical field [0001] The invention relates to the field of composite materials, in particular to a method for preparing a heat insulation pad and the heat insulation pad prepared by the method. Background technique [0002] As a protective device in high temperature environment, heat insulation pad has a very wide range of uses, such as in the aerospace field. When manufacturing a space shuttle, it must be considered that the space shuttle needs to withstand the extremely harsh environment during high-speed flight. At the same time, during the take-off process of the space shuttle entering the predetermined orbit and the recovery process of returning to the ground, due to the effect of air resistance, the surface of the space shuttle flying at high speed will generate frictional heat, which will increase the surface temperature of the aircraft. If there is no good heat insulation System, high temperature will be transmitted to the interior of the aircraft through the skin ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B37/06B32B37/10B32B37/12B32B18/00B32B17/02C09J161/14C09J183/04C09J11/04

CPCB32B37/06B32B17/02B32B18/00B32B37/10B32B37/1284B32B2037/1269C09J11/04C09J161/14C09J183/04

Inventor 关永安王焱廖尔清袁继军叶贵星韩宗辉崔伟涛刘葵

Owner AVIC GUIZHOU AIRPLANE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com