Finger Cutting Equipment

A cutting equipment and finger-shaped technology, applied in the field of finger-shaped cutting equipment, can solve problems such as backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

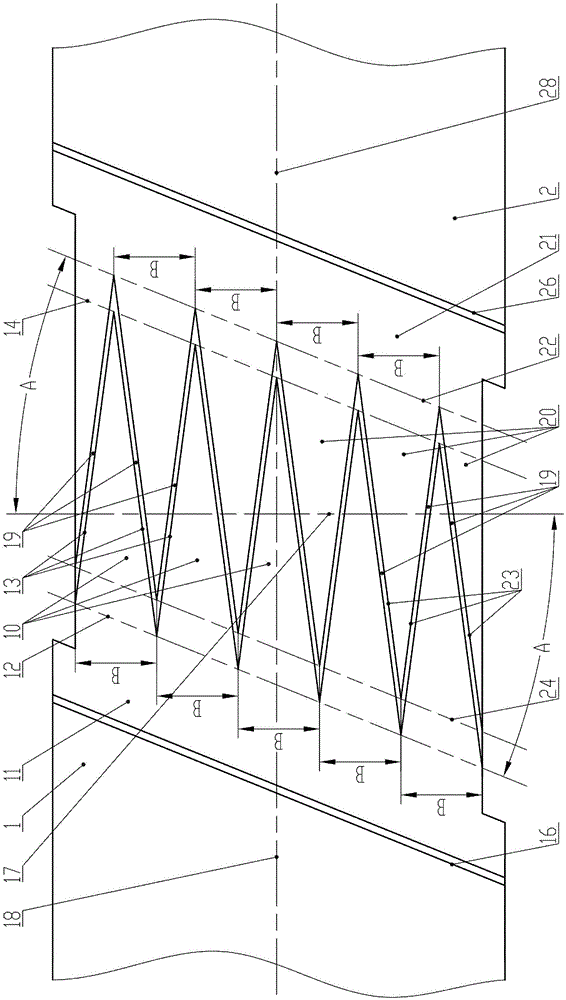

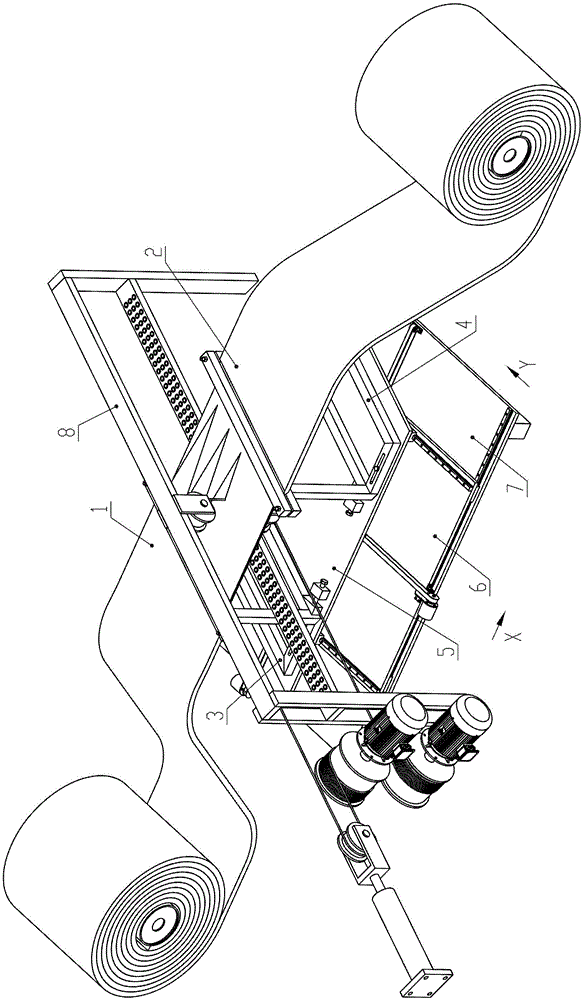

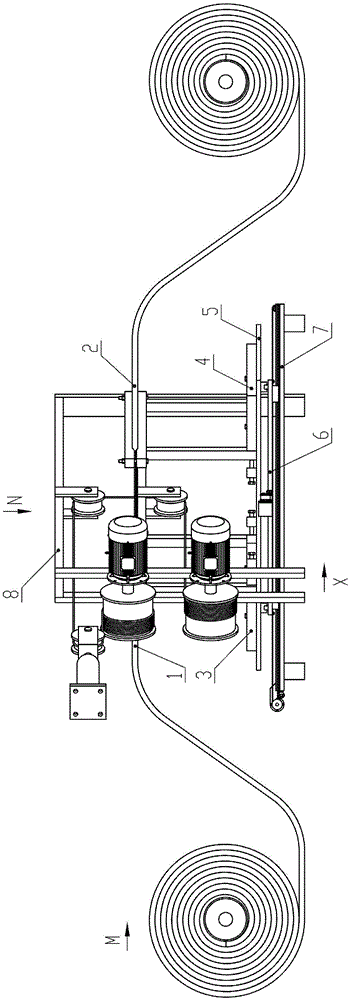

[0070] Example: see Figure 1 to Figure 13 .

[0071] A finger-shaped cutting device, characterized by:

[0072] Including cutting device 8, such as Figure 10 As shown, the cutting device 8 includes a wire storage drum 1 851, a wire storage drum 2 861, a motor 1 852, a motor 2 862, a diamond cutting wire 83, a guide wheel and a supporting platform 84;

[0073] Such as Figure 11 As shown, there is a wire hole 842 on the belt support platform 84, and the folded belt end 1 and belt end 2 2 are placed horizontally and moved along the belt support platform 84;

[0074] One end of the diamond cutting wire 83 is fixed on the wire storage barrel one 851, and is wound many turns on the wire storage barrel one 851 to achieve the purpose of storing the diamond cutting wire 83; the guide wheels include a guide wheel one 82 and a guide wheel two 81, from The diamond cutting wire 83 of wire storage drum 1 851 walks around guide wheel 1 82, passes through wire hole 842, walks around guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com