Target welding clamp and target welding method

A technology for welding fixtures and welding methods, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as poor sputtering surface quality and easy deformation of targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

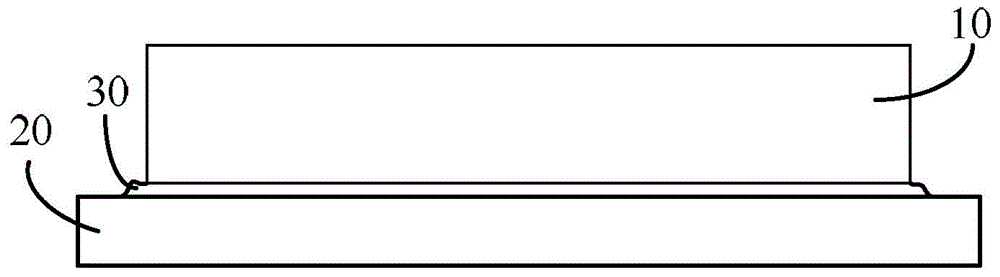

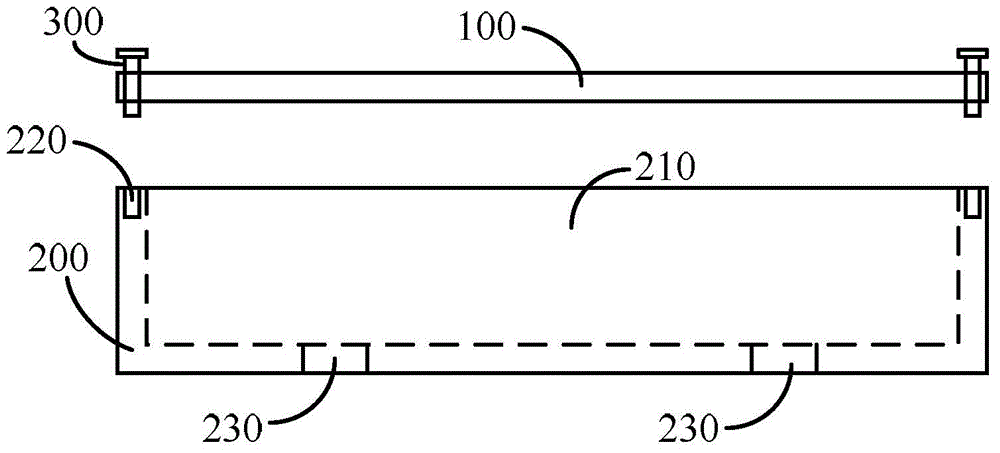

[0055] As mentioned in the background art, in the existing target welding process, the target will be deformed, so further steps such as a leveling process are required to optimize the flatness of the sputtering surface of the target. However, in the actual operation process, if the texture of the target material prepared by the powder metallurgy method is relatively brittle, the target material often breaks during the leveling process, which leads to the scrapping of the target material and affects the yield of the target material.

[0056] Therefore, the present invention provides a target welding jig and a target welding method using the target welding jig. In the process of welding the target blank and the back plate to form the target assembly, the deformation of the target blank can be effectively suppressed, thereby ensuring the flatness of the sputtering surface of the target in the obtained target assembly, and avoiding further damage to the target after the welding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com