Processing and forming combination device of aluminum foil for condenser.

A technology for forming and combining devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems that the waste can not be removed in time, scratch the staff, and inconvenient receiving materials, so as to improve the processing effect and work efficiency. Efficiency, convenient operation and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

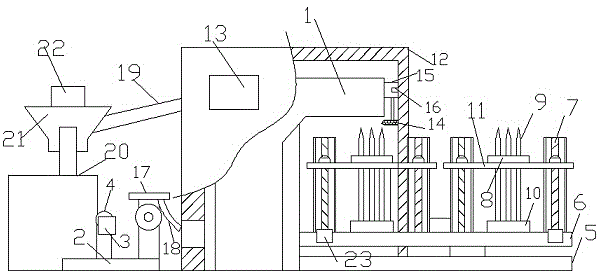

[0016] Such as figure 1 Shown: a combination device for processing and forming aluminum foil sheets for condensers in this embodiment, including a feeding mechanism, a forming device 1 and a receiving device arranged in sequence; the forming device 1 is located in a safety box 12, and the safety box 12 A transparent observation window 13 is fixedly arranged on the top.

[0017] Wherein said feeding mechanism comprises feeding frame 2 and motor 3, and said feeding frame 2 is fixedly provided with transmission shaft 4, wherein transmission shaft 4 is connected and fixed with said motor 3; A fixed material passing roller 17 is arranged beside it; a pressing sheet 18 is arranged above the material passing roller 17 .

[0018] The receiving device includes an operating platform 5, on which a support frame 6 is rotated and fixed, and each end of the support frame 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com