Vinyl acetate catalyst, preparation method and vinyl acetate synthesis method

A technology of vinyl acetate and synthesis method, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as low catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

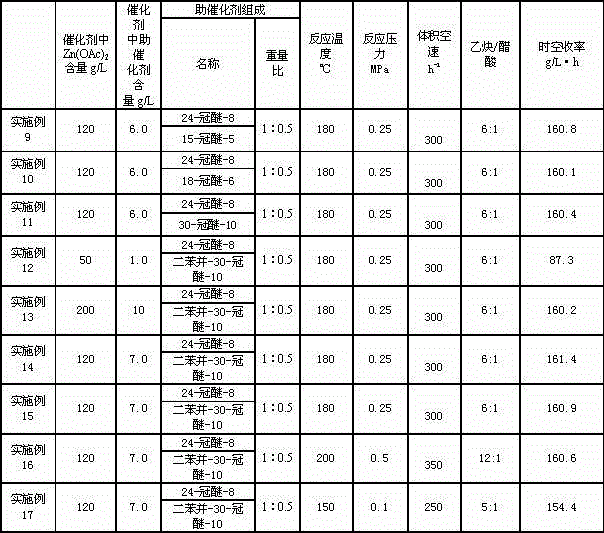

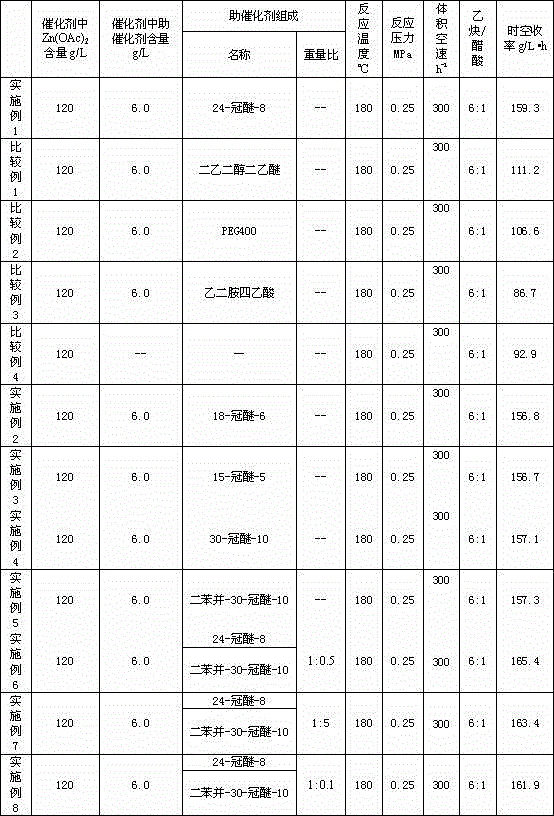

Examples

Embodiment 1

[0016] 1. Catalyst preparation

[0017] (1) Impregnation: impregnate 1L activated carbon carrier with 580ml impregnation solution. Zn(OAc) in the immersion solution 2 The content is 120 g, the content of 24-crown-8 is 6.0 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% acetic acid and 30 wt% water). The carrier is 3 mm in diameter, 2 cm long, and has a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of coal-based cylindrical activated carbon.

[0018] (2) Drying: drying at 100°C to obtain the finished catalyst.

[0019] 2. Catalyst evaluation

[0020] The catalysts synthesized by the above method were evaluated in a laboratory microreactor. The evaluation conditions are: catalyst loading: 30ml catalyst; reaction temperature: 180°C; reaction pressure: 0.25MPa; raw material volume space velocity: 300 h -1 ; Raw material composition: acetylene / acetic acid molar ratio=6:1.

[0021] After the catalyst...

Embodiment 2

[0055] 1. Catalyst preparation

[0056] (1) Impregnation: impregnate 1L activated carbon carrier with 580ml impregnation solution. Zn(OAc) in the immersion solution 2 The content is 120 g, the content of 18-crown ether-6 is 6.0 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% acetic acid and 30 wt% water). The carrier is 3 mm in diameter, 2 cm long, and has a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of coal-based cylindrical activated carbon.

[0057] (2) Drying: drying at 100°C to obtain the finished catalyst.

[0058] 2. Catalyst evaluation

[0059] The catalysts synthesized by the above method were evaluated in a laboratory microreactor. The evaluation conditions are: catalyst loading: 30ml catalyst; reaction temperature: 180°C; reaction pressure: 0.25MPa; raw material volume space velocity: 300 h -1 ; Raw material composition: acetylene / acetic acid molar ratio=6:1.

[0060] After the ca...

Embodiment 3

[0062] 1. Catalyst preparation

[0063] (1) Impregnation: impregnate 1L activated carbon carrier with 580ml impregnation solution. Zn(OAc) in the immersion solution 2 The content is 120 g, the content of 15-crown ether-5 is 6.0 g, and the solvent in the impregnation solution is a mixed solvent of acetic acid and water (70 wt% acetic acid and 30 wt% water). The carrier is 3 mm in diameter, 2 cm long, and has a pore volume of 0.8 cm 3 / g, the specific surface area is 1200 cm 2 / g of coal-based cylindrical activated carbon.

[0064] (2) Drying: drying at 100°C to obtain the finished catalyst.

[0065] 2. Catalyst evaluation

[0066] The catalysts synthesized by the above method were evaluated in a laboratory microreactor. The evaluation conditions are: catalyst loading: 30ml catalyst; reaction temperature: 180°C; reaction pressure: 0.25MPa; raw material volume space velocity: 300 h -1 ; Raw material composition: acetylene / acetic acid molar ratio=6:1.

[0067] After the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com