A catalytic cracking catalyst

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc. Effects of increased activity and heavy oil cracking performance, high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

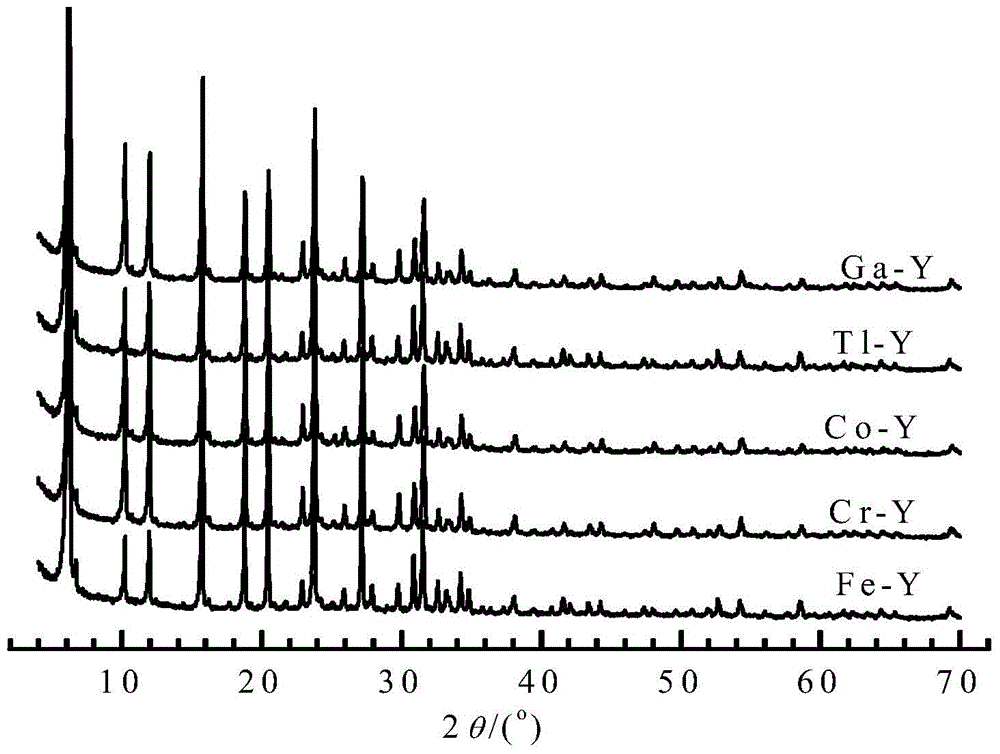

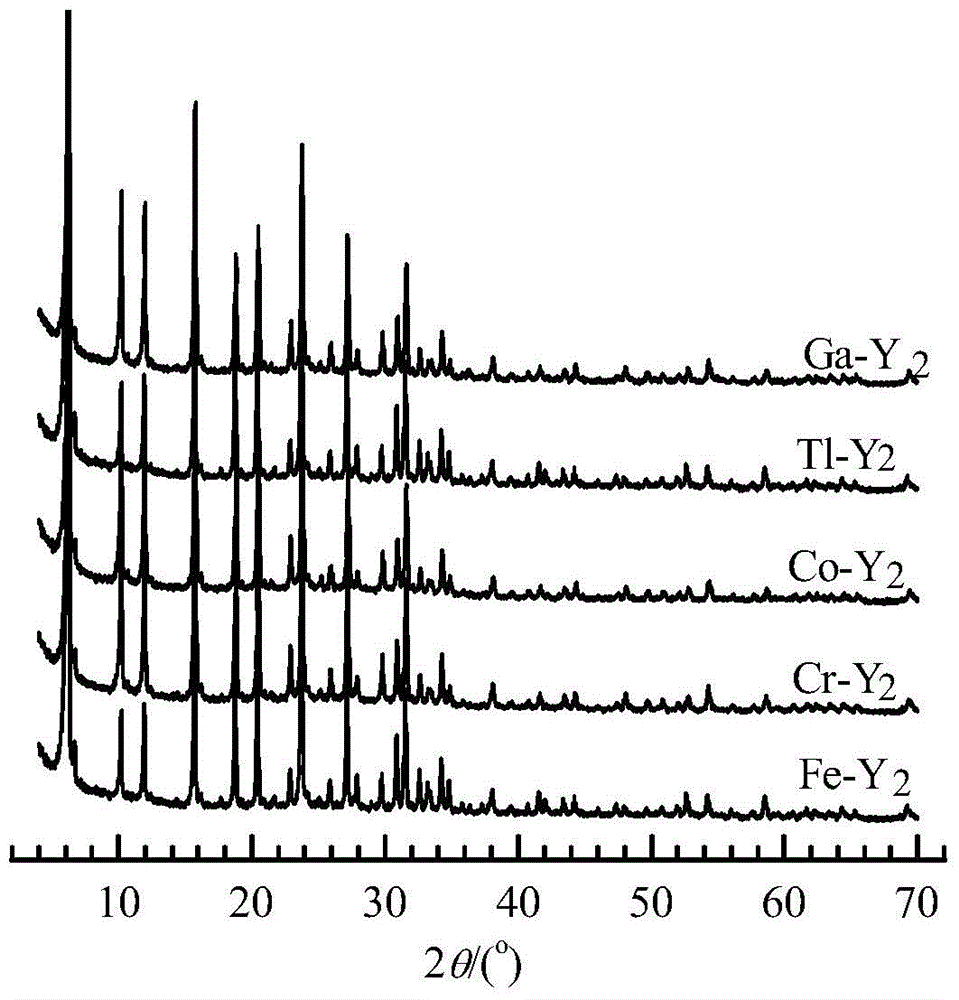

Image

Examples

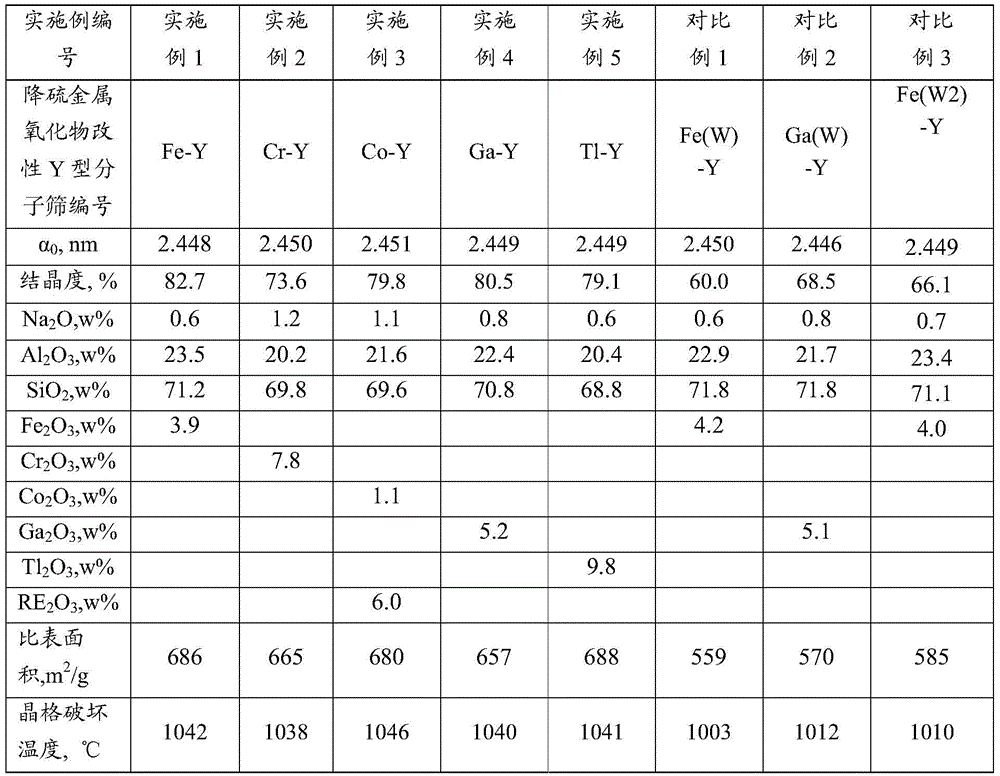

Embodiment 1

[0039] At room temperature, take 150g (dry basis) DASY (0.0) molecular sieve, mix it with 1500ml hydrochloric acid solution with a molar concentration of 1.0mol / L, stir for 30 minutes, filter, wash with 1500ml deionized water, and obtain Y molecular sieve after acid treatment. The sodium oxide content is 0.6% by weight; the Y molecular sieve obtained after the acid treatment is roasted at 300°C for 3 hours to obtain a molecular sieve with a solid content of 97% by weight, which is designated as FZ-1;

[0040] Get 12ml ethanol and add 180ml deionized water, add 5mol / L acetic acid aqueous solution 3ml, adjust solution pH value to 3.7 with 10mol / L ammonium hydroxide aqueous solution, then 30.4g Fe(NO 3 ) 3 9H 2 O was dissolved in the above buffer solution to obtain an impregnating liquid, and the above FZ-1 molecular sieve was mixed with the impregnating liquid evenly, left to stand for 12 hours, dried and roasted at 650°C and 100% water vapor for 2 hours to obtain the present i...

Embodiment 2

[0042] At room temperature, take 200g NaY molecular sieves (dry basis 75% by weight), mix them with 1500ml of hydrochloric acid solution with a molar concentration of 0.5mol / L, stir for 30 minutes, filter, and wash with 1500ml deionized water to obtain NaY molecular sieves after acid treatment. The content of sodium oxide is 1.5% by weight; the obtained NaY molecular sieve after acid treatment is roasted at 300°C for 3 hours to obtain a molecular sieve with a solid content of 96% by weight (water content 4% by weight), which is designated as FZ-2;

[0043] Get 12ml ethanol and add 180ml deionized water, add 5mol / L acetic acid aqueous solution 3ml, adjust solution pH value to 4.5 with 10mol / L ammonia water, obtain buffer solution, 37.6g Cr(NO 3 ) 3 9H 2 O is dissolved in the above buffer solution to obtain an impregnating liquid, and the above molecular sieve FZ-2 is mixed evenly with the impregnating liquid, left to stand for 12 hours, dried and roasted at 500°C and 100% water ...

Embodiment 3

[0045] Take 200g NaY molecular sieve (same as above), beat with 1500g of deionized water, add 45g of ammonium chloride and 33.5ml of RECl 3 solution (its concentration in RE 2 o 3 Calculated as 270g / L), rare earth salt (in RE 2 o 3 Calculated): ammonium salt: NaY molecular sieve: deionized water with a weight ratio of 0.06:0.3:1:10, adjust the pH value of the slurry to 3.8, heat up to 80°C for 2 hours, filter and rinse with water, and then filter the cake Baking at 600°C and 100% steam for 2 hours. The molecular sieve after roasting is mixed with the sulfuric acid solution 1500ml that the molar concentration is 0.2mol / L, stirs 30 minutes, filters, washes with 1500ml deionized water, obtains the Y molecular sieve after the acid treatment, and its sodium oxide content is 1.2% by weight; The resulting acid-treated Y molecular sieve was calcined at 350°C for 3 hours to obtain a molecular sieve with a solid content of 97% by weight, denoted as FZ-3;

[0046] Get 12ml ethanol a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com