Composite photocatalyst-DyVO4/g-C3N4 and preparation method thereof

A technology of g-c3n4 and catalyst is applied in the field of photocatalysis, which can solve the problems of low photocatalytic efficiency and enhanced catalytic effect of composite photocatalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

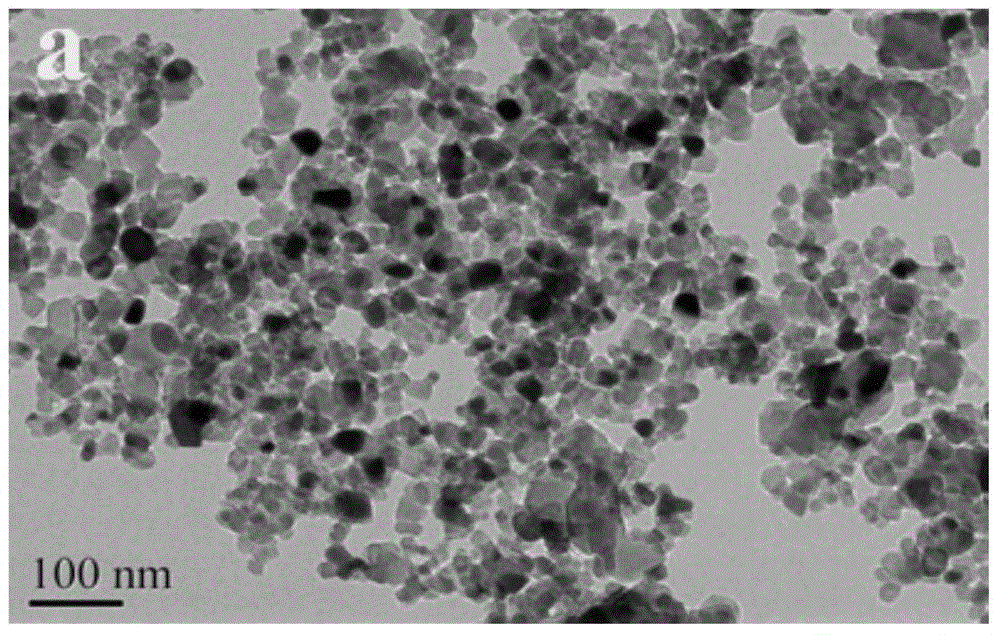

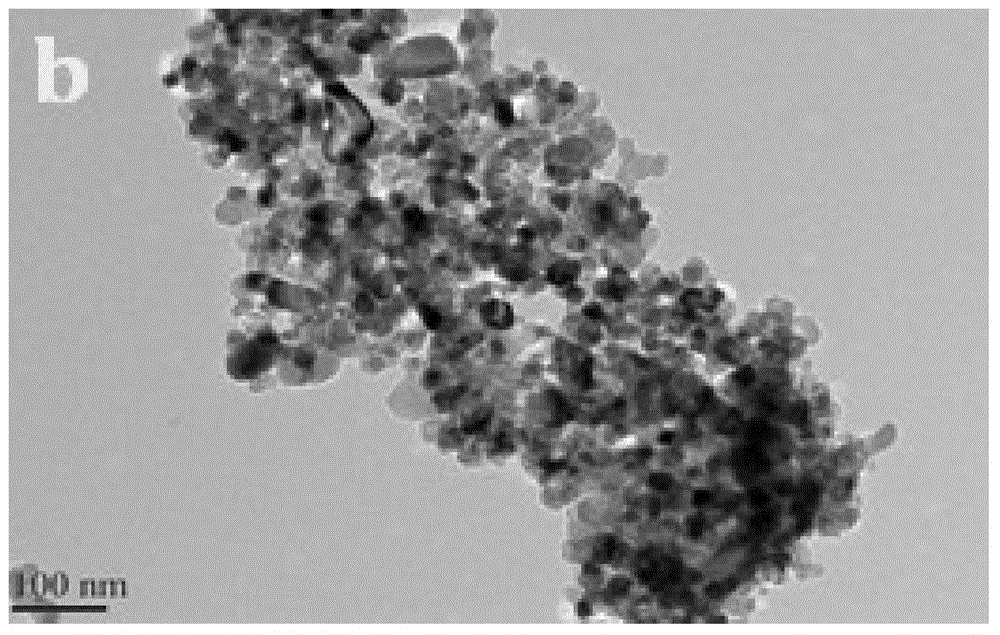

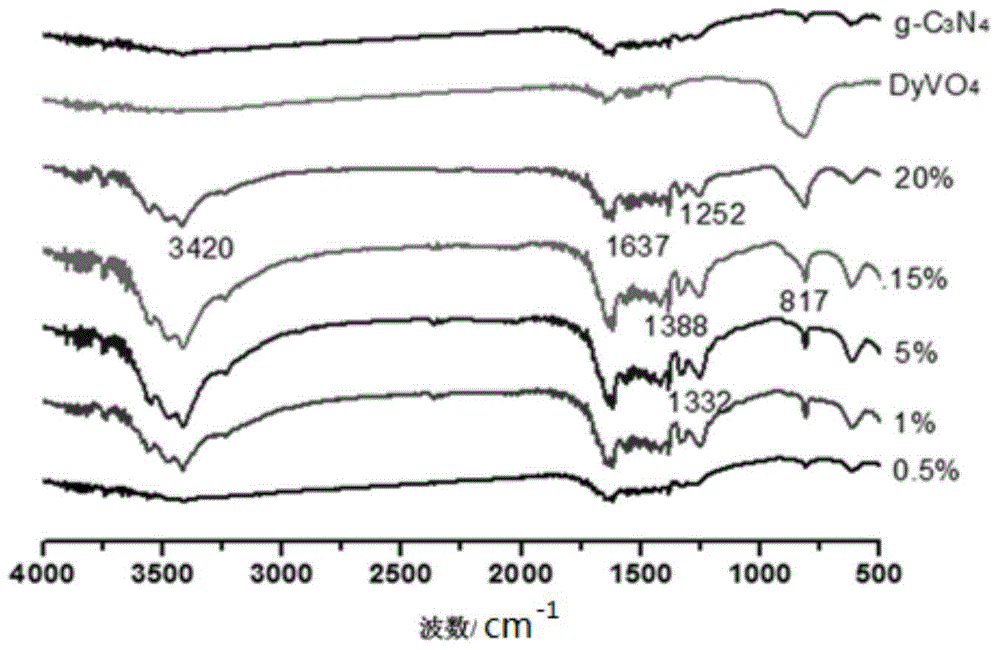

Image

Examples

Embodiment 1

[0088] The preparation (0.5%) of embodiment 1 composite photocatalyst

[0089] (1) Weigh 15.0g of melamine and put it into an alumina crucible (with a cover), place it in a muffle furnace, bake it at 500°C for 5h, and cool it down to room temperature naturally to obtain g-C 3 N 4 Sample, namely product I.

[0090] (2) Mix 2 mol of ammonium metavanadate and 1 mol of dysprosium nitrate, dissolve them in distilled water respectively, adjust the pH of the system to 8.0 with ammonia water after mixing the two solutions, and a yellow turbid substance is formed; after standing at room temperature for 1 hour, filter and put Vacuum oven at 80°C for 12h, then moved into an alumina crucible, placed in a muffle furnace and roasted at 400°C for 3h, cooled naturally to room temperature to obtain a light brown solid DyVO 4 , namely product II.

[0091] (3) Accurately weigh 0.0050g of product II and 0.9950g of product I, mix and grind in an agate mortar for 30 minutes, transfer to an alu...

Embodiment 2

[0092] The preparation (1%) of embodiment 2 composite photocatalysts

[0093] (1) Weigh 15.0g of urea into a dry and clean small beaker, dissolve it in 20mL of distilled water, and react at a constant temperature in a water bath at 60°C. After the solvent water is evaporated to dryness, put the obtained sample into an alumina crucible (covered ), placed in a muffle furnace, calcined at 400°C for 5h, and cooled naturally to room temperature to obtain g-C 3 N 4 Sample, namely product I.

[0094] (2) Mix 1 mol of ammonium metavanadate and 2 mol of dysprosium nitrate, dissolve them in distilled water respectively, adjust the pH of the system to 7.5 with ammonia water after mixing the two solutions, and a yellow turbid substance is formed; after standing at room temperature for 3 hours, filter and put Vacuum oven at 120°C for 10h, then moved into an alumina crucible, placed in a muffle furnace and roasted at 700°C for 3h, cooled naturally to room temperature to obtain a light b...

Embodiment 3

[0096] The preparation (2.5%) of embodiment 3 composite photocatalysts

[0097] (1) Weigh 15.0g of dicyandiamide and put it into an alumina crucible (covered), place it in a muffle furnace, roast it at 300°C for 4 hours, and cool it down to room temperature naturally to obtain g-C 3 N 4 Sample, namely Product I.

[0098] (2) Mix 1 mol of ammonium metavanadate and 1.5 mol of dysprosium nitrate, dissolve them in distilled water respectively, adjust the pH of the system to 6.5 with ammonia water after mixing the two solutions, and a yellow turbidity is generated; after standing at room temperature for 2 hours, filter and put Put it into a vacuum oven at 110°C for 18h, then move it into an alumina crucible, place it in a muffle furnace and bake at 900°C for 2h, and cool naturally to room temperature to obtain a light brown solid DyVO 4 , namely product II.

[0099] (3) Accurately weigh 0.0250g of product II and 0.9750g of product I, mix and grind in an agate mortar for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com