A kind of preparation method of residue hydrodemetallization catalyst

A technology for hydrodemetallization and residual oil hydrogenation, which is used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as unsatisfactory mechanical strength of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

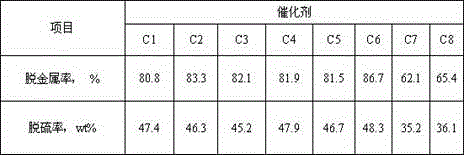

example 1

[0018] Weigh 100 grams of the above-mentioned self-made clover-shaped alumina (water content 25%), use 150ml containing 15 grams of xylitol, MoO 3 105 grams, 15 grams of NiO impregnating solution impregnated the above carrier for 3 hours, filtered off the excess solution, and dried at 110°C for 8 hours. The dried material was first calcined at 260°C for 4 hours under a nitrogen atmosphere, and then in Calcined at 600°C for 4 hours, and finally at 400°C for 3 hours in an air atmosphere. The residue hydrodemetallization catalyst C1 of the present invention was prepared.

example 2

[0020] Same as Example 1, except that the impregnating solution contains 25 grams of sorbitol, mannitol, and arabic alcohol at a mass ratio of 1:1:1, to obtain the residual oil hydrodemetallization catalyst C2 of the present invention.

example 3

[0022] Same as Example 1, except that the soaking solution contains 8 grams of glucose, and the residue hydrodemetallization catalyst C3 of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com