A slurry bed loop reactor and its application and a method for producing hydrogen peroxide

A loop reactor, hydrogen peroxide technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the temperature problem in the bed Uneven distribution, low catalyst utilization efficiency, large catalyst liquid holding capacity, etc., to avoid flow dead zones and hot spots, uniform catalyst and gas distribution, and reduce operating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

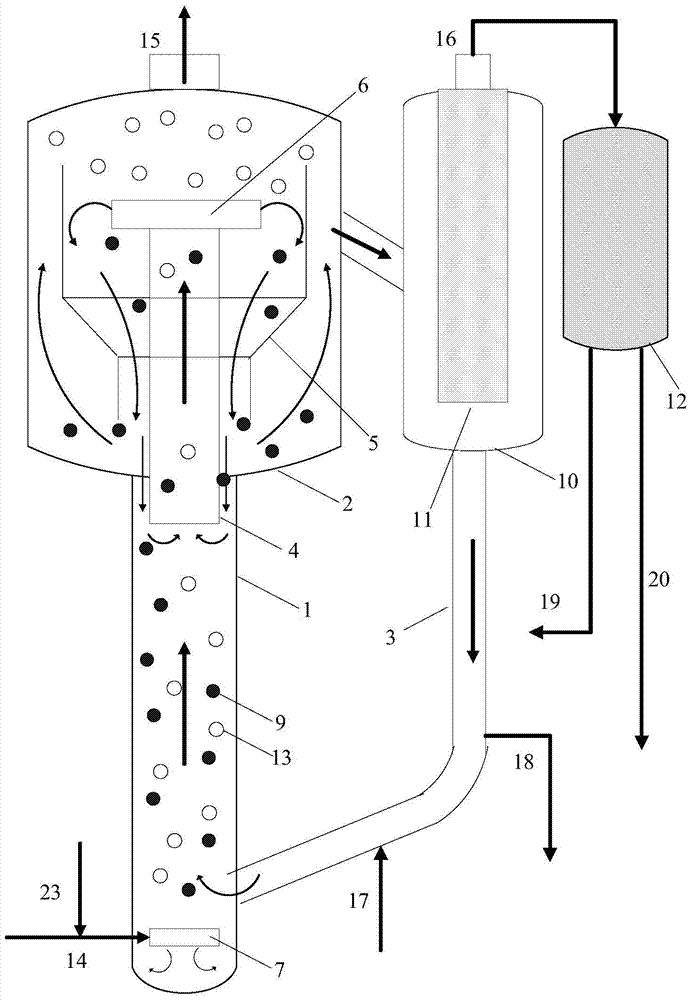

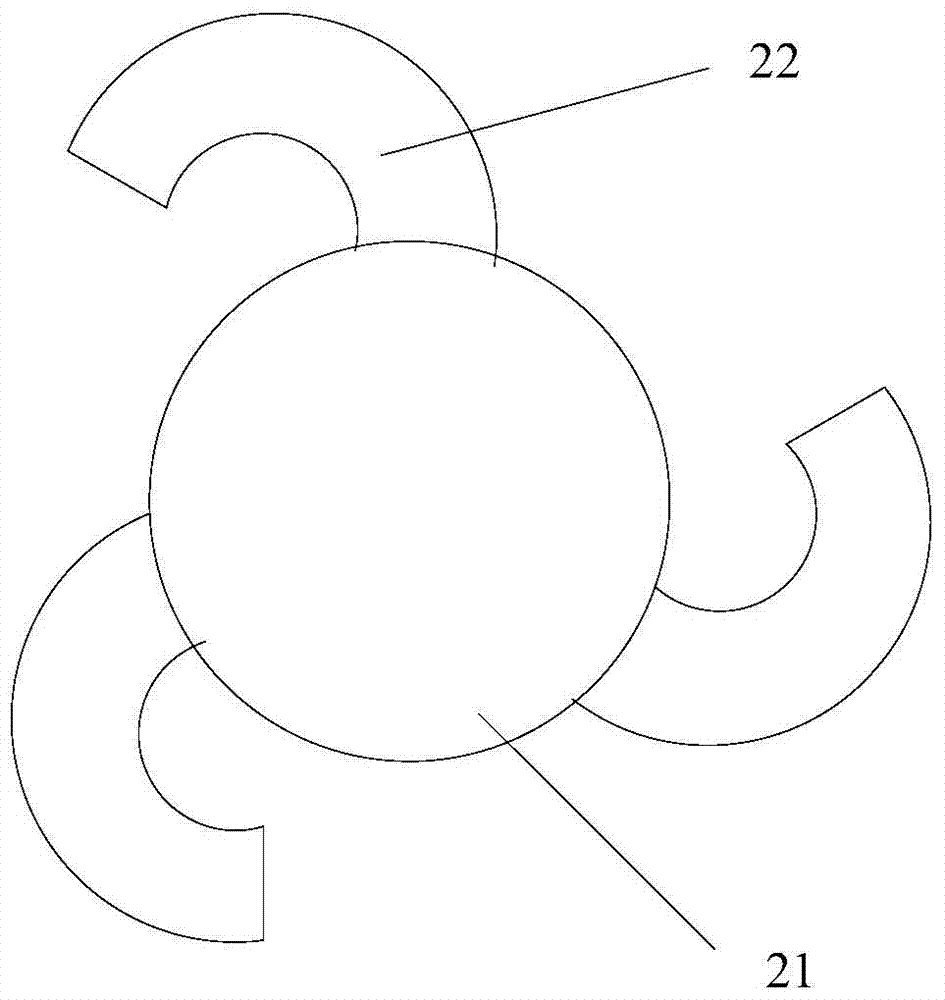

[0023] A slurry bed loop reactor provided by the present invention comprises a riser, an enlarged section with an enlarged upper diameter of the riser, and a solid-liquid separator, the enlarged section communicates with the upper part of the solid-liquid separator, and the solid-liquid separation The bottom of the riser communicates with the bottom of the riser; a three-phase separator with double sleeve structure is set in the expansion section, a raw material inlet is provided at the bottom of the riser, and a gas outlet is provided at the top of the expansion section. A filter assembly is arranged in the solid-liquid separator, and the upper part of the solid-liquid separator is provided with a clear liquid outlet through the filter assembly.

[0024] Preferably, the three-phase separator is a double-sleeve structure, wherein the diameter ratio of the outer cylinder to the riser is 1.2 to 5:1, more preferably 2 to 4:1; the diameter ratio of the inner cylinder to the riser i...

Embodiment 1

[0064] Example 1 illustrates the effect of the slurry bed reactor provided by the present invention applied to the preparation of hydrogen peroxide by anthraquinone method.

[0065] Attached figure 1 In the slurry bed reactor shown, the size of the reaction riser is Φ150×5000mm, the size of the expansion section is Φ450×1500mm, the size of the inner cylinder is Φ120×2000mm, the length of the inner cylinder extending into the lower part of the riser is 1000mm, and the outer cylinder is composed of Composed of two sections, the size of the upper section is Φ400×500mm, and the size of the lower section is Φ300×500mm. The top of the inner cylinder is connected with the hydraulic centrifuge. A fluid outlet pipeline is arranged at the gap between the outer sleeve and the reactor to connect the solid-liquid separator. The size of the solid-liquid separator is Φ150×1500mm, and there are two sets of ceramic membrane filter components with a height of 500mm installed inside. It is set...

Embodiment 2

[0069] Example 2 illustrates the effect of the slurry bed reactor provided by the present invention applied to the preparation of hydrogen peroxide by anthraquinone method.

[0070] Attached figure 2 In the slurry bed reactor shown, the size of the reaction riser is Φ150×5000mm, the size of the expansion section is Φ450×2000mm, the size of the inner cylinder is Φ150×1000mm, the inner cylinder is connected to the bottom of the riser, and has 8 apertures It is a 10mm round hole, and the size of the outer cylinder is Φ400×1500mm. A fluid outlet pipeline is arranged at the gap between the outer sleeve and the reactor to connect the solid-liquid separator. The top of the inner cylinder is connected with the hydraulic centrifuge. The size of the solid-liquid separator is Φ150×1500mm, and there are two sets of ceramic membrane filter components with a height of 500mm installed inside. It is set to automatically recoil when the pressure difference of each filter reaches 0.06MPa, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com