Self-pressure boosting system for double-end mechanical seal

A technology of mechanical seal and pressurization system, applied in the direction of pressure vessel/vacuum vessel, pressure vessel used in chemical process, etc., can solve the problems of economic loss, flammability, material loss, etc., achieve good sealing conditions, simple structure, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

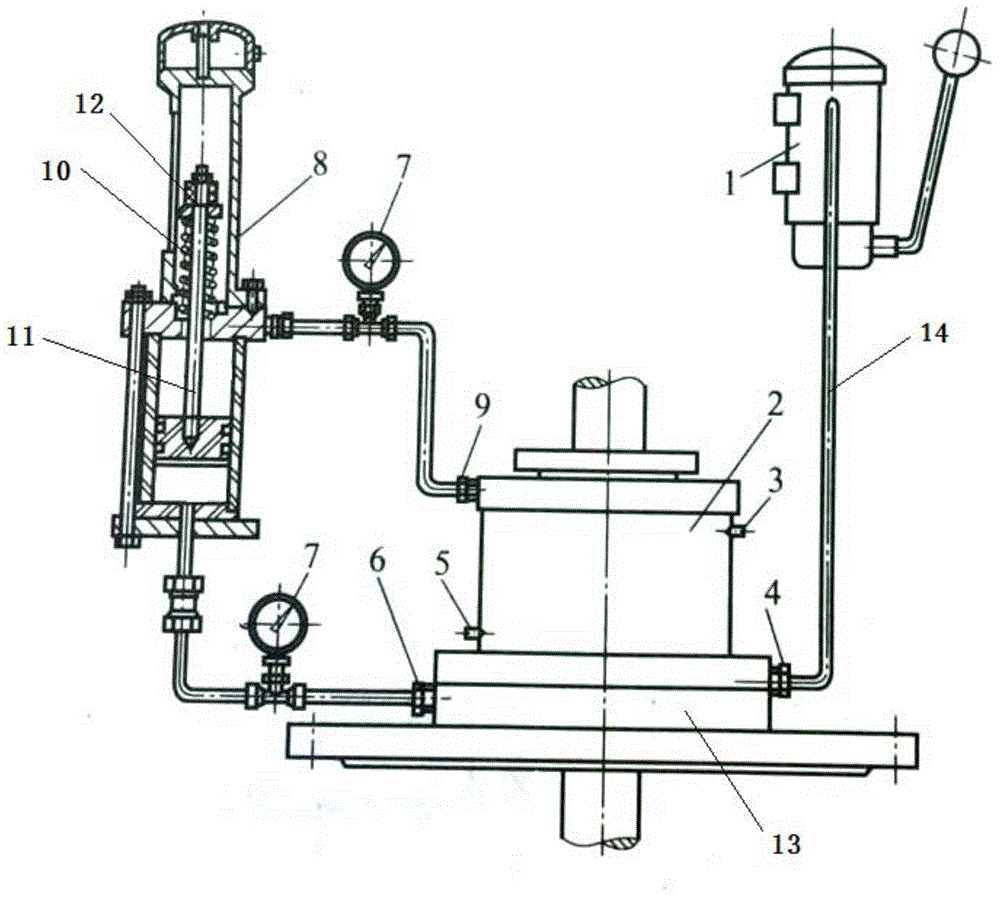

[0013] like figure 1 The self-pressure boosting system of a double-end mechanical seal shown includes a mechanical seal device 2, a balance tank 8 and a reaction kettle 13, and the upper part of the balance tank 8 passes through the seal liquid between the pipeline and the seal cavity of the mechanical seal device 2 The inlet 9 is connected, and the lower part is connected with the gas communication pipe 6 in the reactor 13 through a pipeline. The piston 12 and the piston rod 11 are arranged in the balance tank 8, and the piston 12 and the piston rod 11 cooperate. The piston 12 is sealed with the cylinder wall of the balance tank 8 by an O-ring, the piston rod 11 slides in the axial direction, and the piston rod 11 is provided with a spring 10 . The sealing chamber of the mechanical seal device 2 is provided with a jacket cooling water outlet 3 and a jacket cooling water inlet 5 . Pressure gauges 7 are provided on the pipes connecting the balance tank 8 , the mechanical seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com