Microsphere and application thereof in hemostasis of wound

A technology of microspheres and collagen, applied in the field of microspheres, can solve the problems of high price and unpopularity, and achieve the effect of high adhesion rate, promoting adhesion and improving cross-linking degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 1.5g of sodium alginate, 0.5g of carboxymethyl chitosan and 0.025g of collagen into 100ml of water and dissolve to prepare a matrix solution.

[0038] Mix 250ml of liquid paraffin with 18.75ml of Tween 80, add matrix solution, and 10ml of 2w / w% calcium chloride, accompanied by rapid stirring, to carry out cross-linking reaction to prepare microspheres.

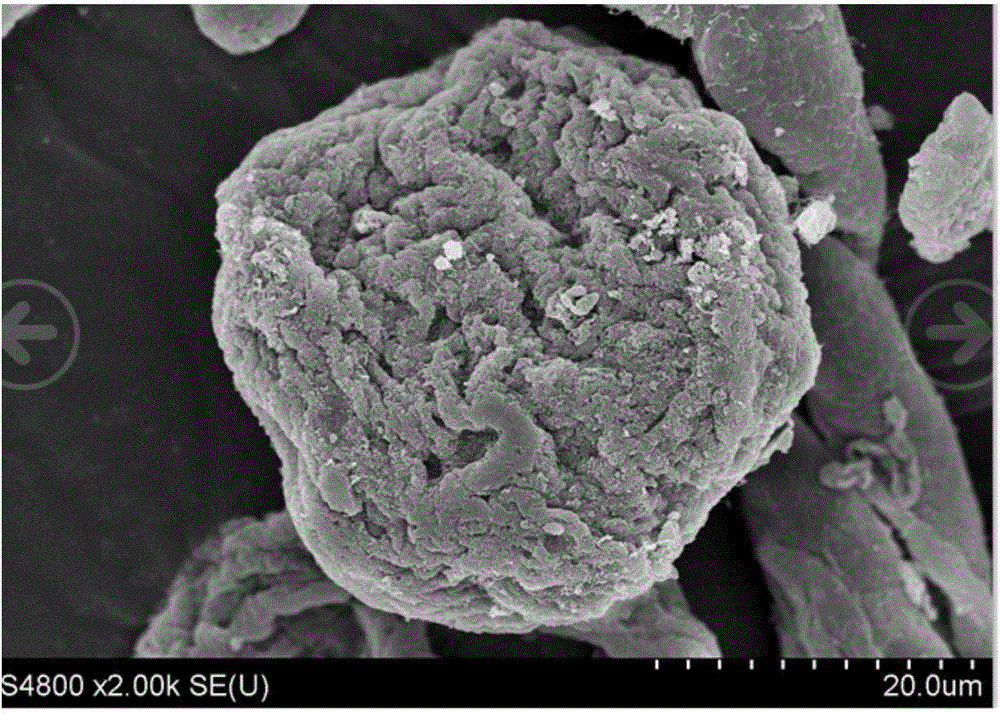

[0039] After the end, add 500ml of ethanol and soak for 2 hours. After the microspheres and the solution are separated, remove the clear liquid, filter the precipitate to further remove the excess solution, and put it in a vacuum drying oven at 60°C for drying. The morphology of the dried microspheres under the electron microscope is as follows: figure 1 As shown, the particle size distribution of more than 90% of the microspheres is between 10 μm and 100 μm as detected by the laser diffraction particle size analyzer.

Embodiment 2

[0041] Add 1.0 g of sodium alginate, 0.5 g of carboxymethyl chitosan and 0.025 g of collagen into 100 ml of water and dissolve to prepare a matrix solution.

[0042] Mix 250ml of soybean oil with 18.75ml of Tween 60, add matrix solution, and 10ml of 4w / w% calcium chloride, accompanied by rapid stirring, to carry out cross-linking reaction to prepare microspheres.

[0043] After the end, add 500ml of ethanol and soak for 2 hours. After the microspheres and the solution are separated, remove the clear liquid, filter the precipitate to further remove the excess solution, and put it in a vacuum drying oven at 60°C for drying. The dried microspheres are detected by a laser diffraction particle size analyzer, and the particle size distribution of more than 90% of the microspheres is between 10 μm and 100 μm.

Embodiment 3

[0045]Add 0.5g of sodium alginate, 0.5g of carboxymethyl chitosan and 0.025g of collagen into 100ml of water and dissolve to prepare a matrix solution.

[0046] Mix 250ml of castor oil with 18.75ml of lecithin, add matrix solution, and 10ml of 2w / w% calcium chloride, accompanied by rapid stirring, to carry out cross-linking reaction to prepare microspheres.

[0047] After the end, add 500ml of ethanol and soak for 2 hours. After the microspheres and the solution are separated, remove the clear liquid, filter the precipitate to further remove the excess solution, and put it in a vacuum drying oven at 60°C for drying. The dried microspheres are detected by a laser diffraction particle size analyzer, and the particle size distribution of more than 90% of the microspheres is between 10 μm and 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com