Ventilated condensing device of water tank type cleaning machine

The technology of a sink type washing machine and a condensing device is applied in the direction of the washing machine/rinsing machine parts of tableware, etc., which can solve the problems of damp cabinets, complicated pipeline structure, occupying space on the outer wall of the sink, etc., so as to improve the utilization rate and simplify the pipeline. Road structure, ensure the effect of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

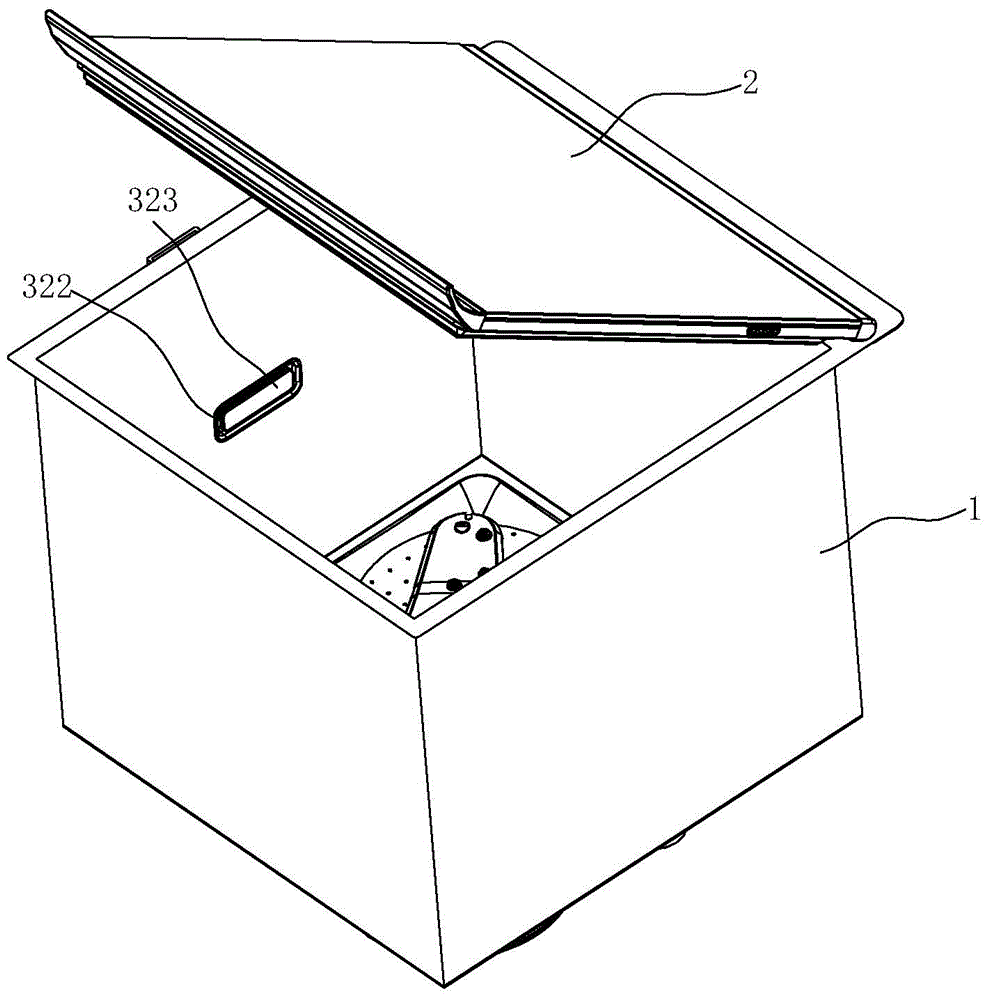

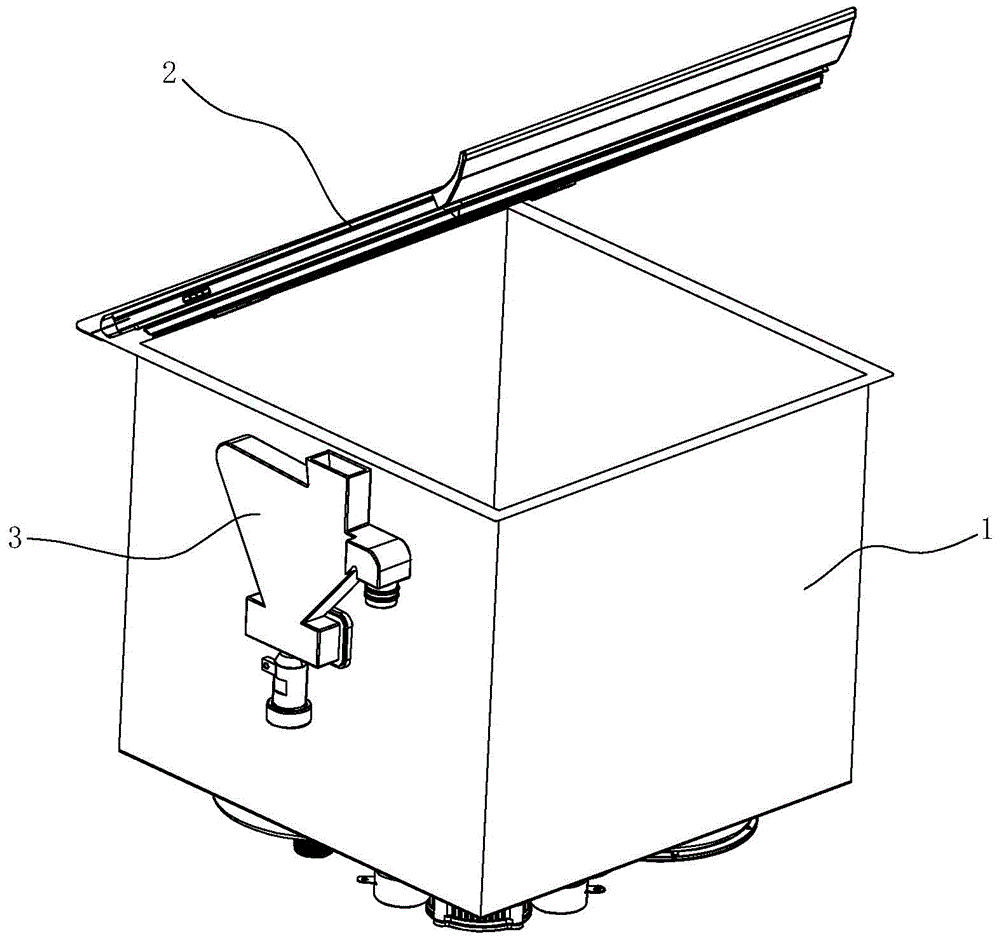

[0023] see figure 1 and figure 2 , a kind of sink type cleaning machine that uses ventilating condensing device of the present invention, can be used for washing dishes, vegetables, fruit etc. 1 can be an ordinary household sink, and the sink body 1 and the cover plate 2 form a washing space to accommodate the above-mentioned dishes, vegetables, fruits, etc., and clean them.

[0024] The sink type cleaning machine is also equipped with a cleaning mechanism, a heating component, an ultrasonic cleaning component, etc. For details, please refer to the disclosure of the applicant’s Chinese patent application number 201320889945.4, and will not be repeated here. Other structures in the prior art may also be adopted for the heating assembly and the cleaning mechanism in the sink type washing machine.

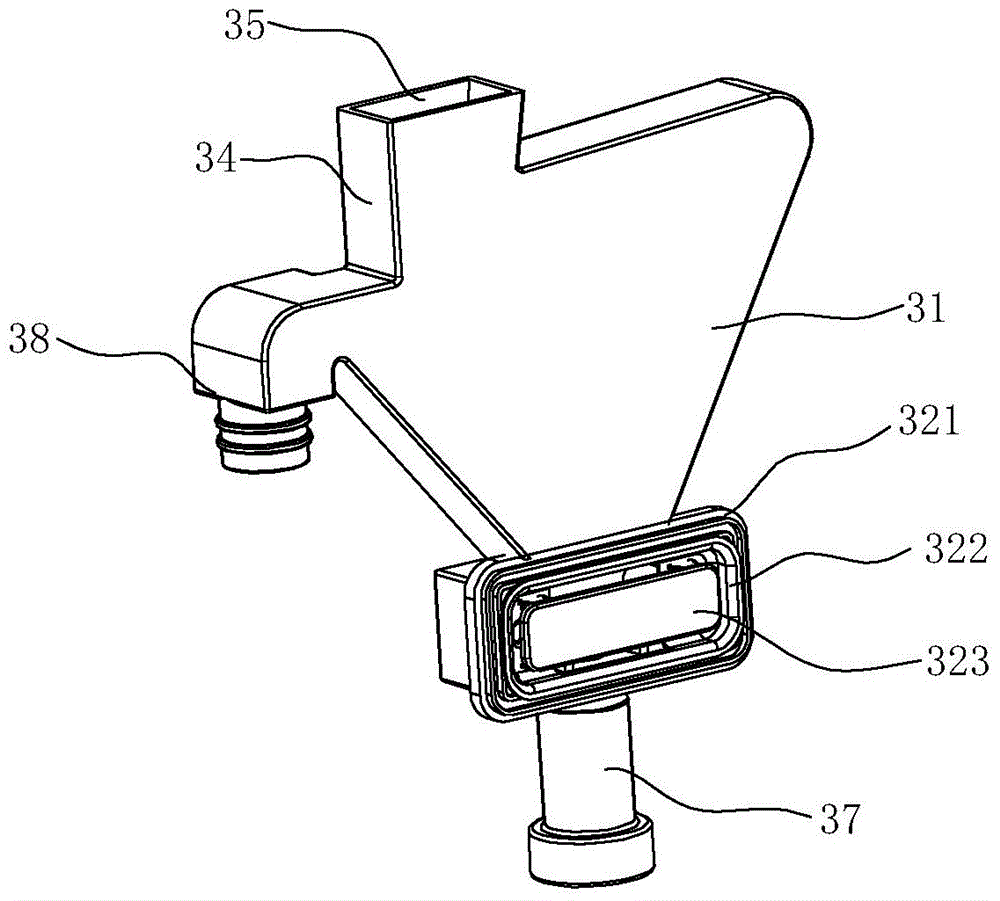

[0025] One side wall of the water tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com