Reconstituted tobacco shredding device

A technology for reconstituted tobacco leaves and shredded tobacco, which is applied in the fields of tobacco, tobacco processing, application, etc. It can solve the problems of large equipment occupation area, film running, and long process, so as to reduce the consumption of production materials, improve the uniformity of length and width, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

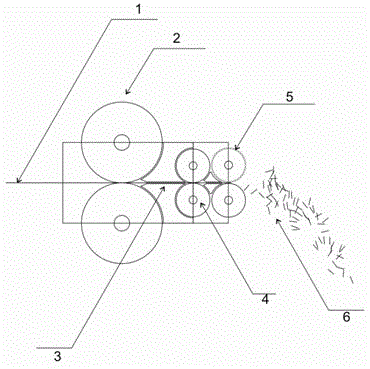

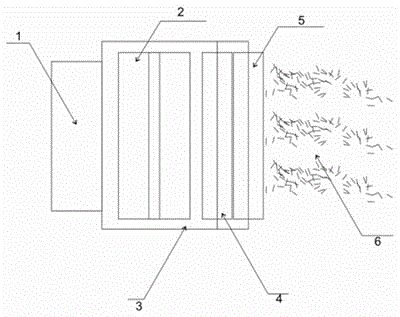

[0025] Such as figure 1 , 2 As shown, the reconstituted tobacco leaf cutting equipment of the present invention is composed of a material guide wheel set 2, a material stopper 3, a parallel disc knife 4, a cross cutting roller knife 5 and a frame, and the material guide wheel set 2, the material stopper 3. Parallel disc cutter 4 and cross-cutting roller cutter 5 are installed sequentially in the horizontal direction. The material stopper 3 is located on the center line between the upper and lower rollers of the material guide wheel group 2, and the whole device is placed on the frame.

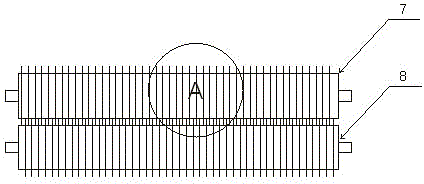

[0026] Described parallel disc knife is made up of upper disc knife roll 7 and lower disc knife roll 8, and the parallel disc knife blade pitch is 0.9mm, as image 3 with Figure 4 shown.

[0027] The cross-cut silk roller knife 5 is composed of an upper cross-cut silk roller knife and a lower cross-cut silk roller 11, and the upper cross-cut silk roller knife is composed of an upper cross-...

Embodiment 2

[0035] Will figure 1 The shown equipment rotates 90 degrees clockwise, and the distance between the parallel disc cutter blades is 20 mm, and the others are the same as in Embodiment 1.

[0036] working principle:

[0037] The reconstituted tobacco leaves prepared in the drying process are rolled into rolls, or cut into certain widths and rolled into rolls. The rolls pass through the unwinder and tension control device and are vertically transported by the material guide wheel group 2 into the material stopper 3. The limiter controls the material is not easy to wrinkle.

[0038] The reconstituted tobacco leaves are cut into strips with a width of 20 mm under the high-speed rotation of the parallel disc cutters through the parallel disc cutters 4 installed at the end of the material stopper. The cut strips are fed into the cross-cutting roller knife 5 installed at the rear end, and the cross-cutting roller knife is further cut into reconstituted shredded tobacco with a width...

Embodiment 3

[0040] The equipment is the same as in Example 1, wherein the distance between the parallel disc cutter blades is 30mm.

[0041] working principle:

[0042] The reconstituted tobacco leaves prepared in the drying process are cut into certain lengths and widths and then sorted into stacks. The stacked reconstituted tobacco leaves are transported horizontally by the material guide wheel set 2 to the material limiter 3 through the paging machine. The material limiter controls the material to prevent wrinkles . The following is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com