Industrial circulating water shrimp culturing method capable of increasing efficiency

A water-circulating and high-efficiency technology, applied in the field of shrimp farming, can solve the problem of low yield and achieve the effect of increasing production, good benefit and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

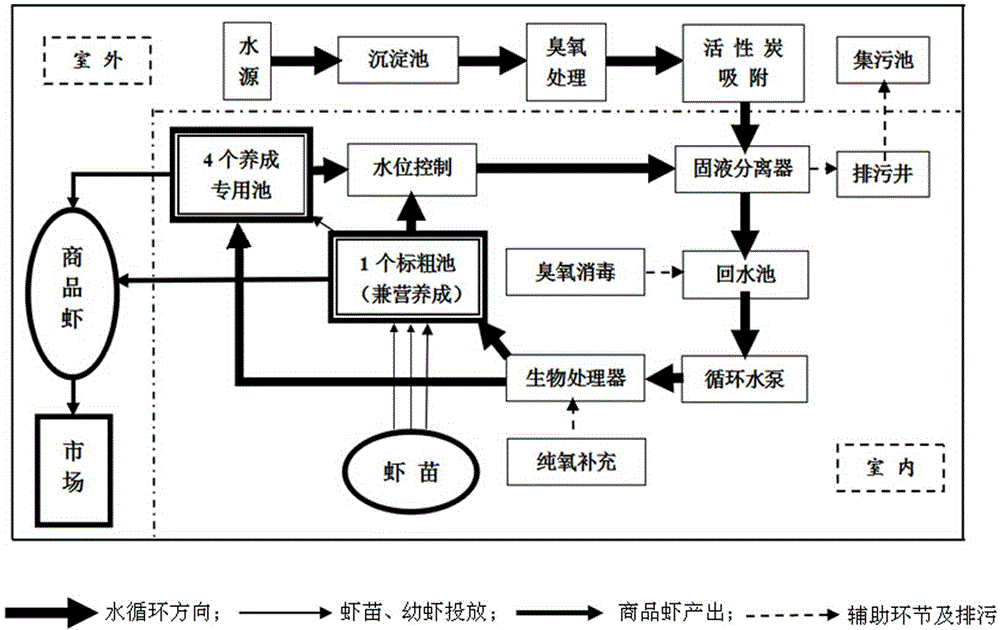

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Such as figure 1 As shown, the present invention relates to industrialized circulating water culture of Penaeus vannamei. The industrialized circulating water method for raising shrimps with improved efficiency adopts 5 shrimp ponds as a combination, and 1 standard thick pond is mainly used for centralized standard thick, timely and concurrently. Nutritious growth; 4 special ponds for growing commercial shrimp, combined with centralized standardization and evacuation; each pond is equipped with an independent circulating water system; water is introduced from an external water source, sedimentation in the sedimentation tank, ozone sterilization and detoxification, After activated carbon adsorption treatment, it enters the indoor solid-liquid separator, removes solid matter and flows into the return pool (if necessary, it is treated with ozone here); then it is extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com