Intelligent grating type plant cultivating device and fabrication method and cultivating method of intelligent grating type plant cultivating device

An intelligent, grating technology, applied in botany equipment and methods, diffraction grating, greenhouse cultivation, etc., can solve the problems of high cost, cost loss, and high cost of LED lamp construction equipment and foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

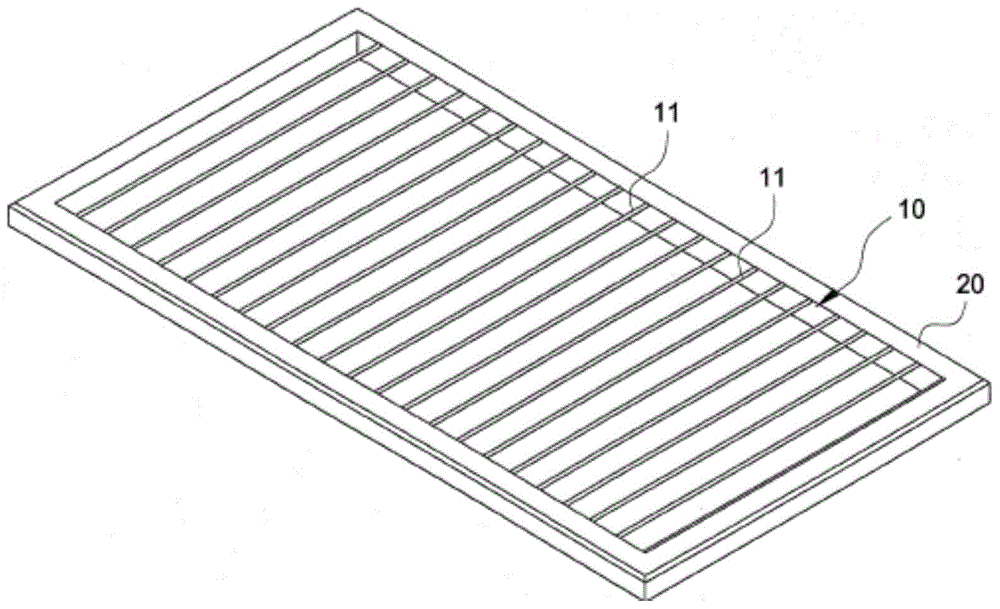

[0056] Embodiment 1 The intelligent grating type plant cultivation device of the present invention

[0057] In order to achieve the above-mentioned purpose of the present invention, the present invention firstly designs a smart grating type plant cultivation device. The intelligent grating type plant cultivation device of the present invention includes at least one grating 10, and the grating 10 is used to cover the periphery of the plant 30 being planted, such as Figure 9 , 10 shown. The grating 10 has a color corresponding to the wavelength of light required for plant growth. When sunlight first irradiates the grating 10, the grating 10 has a color corresponding to the wavelength of light required by the plant 30 in planting, and this color will filter out the light of other wavelengths in the sunlight, leaving only the light of the wavelength required by the plant 30. The light is reflected, passes through the grating 10, and then passes through the grating 10 to irradi...

Embodiment 2

[0060] Embodiment 2 The preparation method of the intelligent grating type plant cultivation device of the present invention

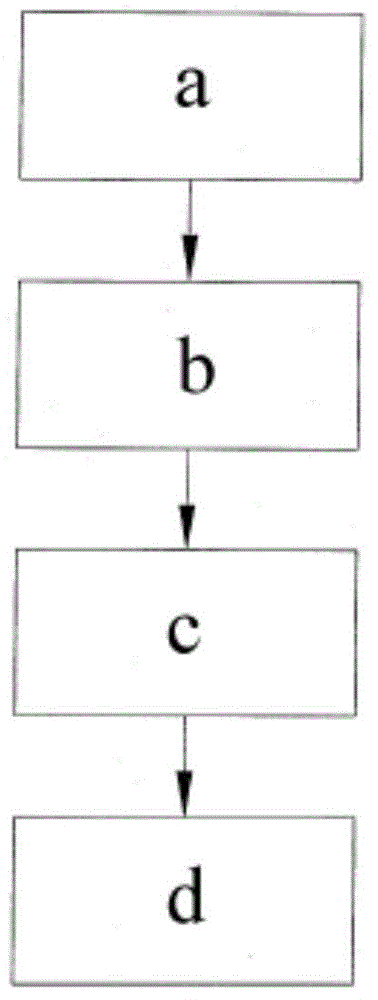

[0061] Please refer to figure 1 , 3 As shown, in order to specifically prepare the intelligent grating type plant cultivation device of the present invention, the present invention designs a kind of concrete method for making, and its method for making comprises:

[0062] (a) Confirm and record the wavelength of light required for the growth period of the plant;

[0063] (b) Preparation includes a specific amount of polymer base material and a specific amount of light conversion material, and mixing the base material and the light conversion material to form a masterbatch;

[0064] (c) Mix the masterbatch with a specific amount of polymer substrate to form a grating raw material, process the grating raw material into a grating substrate, and use the grating substrate to make a plurality of light-transmitting parts distributed in an array and can be ...

Embodiment 3

[0070] Embodiment 3 The intelligent grating type plant cultivation method of the present invention

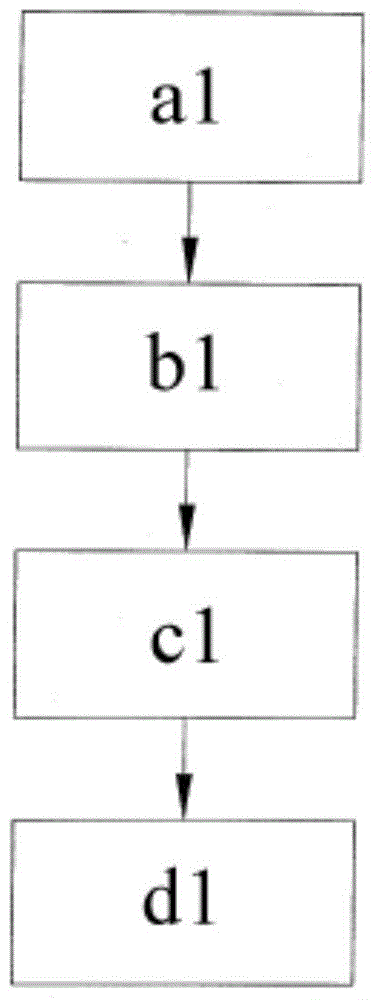

[0071] Such as Figures 2 to 4 And shown in 9, intelligent grating type plant cultivation method of the present invention, comprises:

[0072] (a1) Provide the intelligent grating type plant cultivation device made by the above method;

[0073] (b1) providing the plant 30 identified in (a1) above;

[0074] (c1) planting the plant 30 so that the plant 30 is located in a place where sunlight can shine;

[0075] (d1) Place the grating 10 of the device in (a1) between the plant 30 and the sunlight, let the sunlight reach the grating first, filter the sunlight by the grating 10, and let the light of the wavelength required for the growth of the plant 30 pass through The plant 30 is delivered to irradiate.

[0076] Wherein, since the plant growth process has multiple different growth periods, the wavelength of light required for each growth period will be different. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com