Sealing structure

A technology of sealing structure and outer peripheral surface, which is applied in the direction of engine sealing, engine sealing device, machine/engine, etc., can solve the problem of sealing ring 120 expansion and deformation, and achieve excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

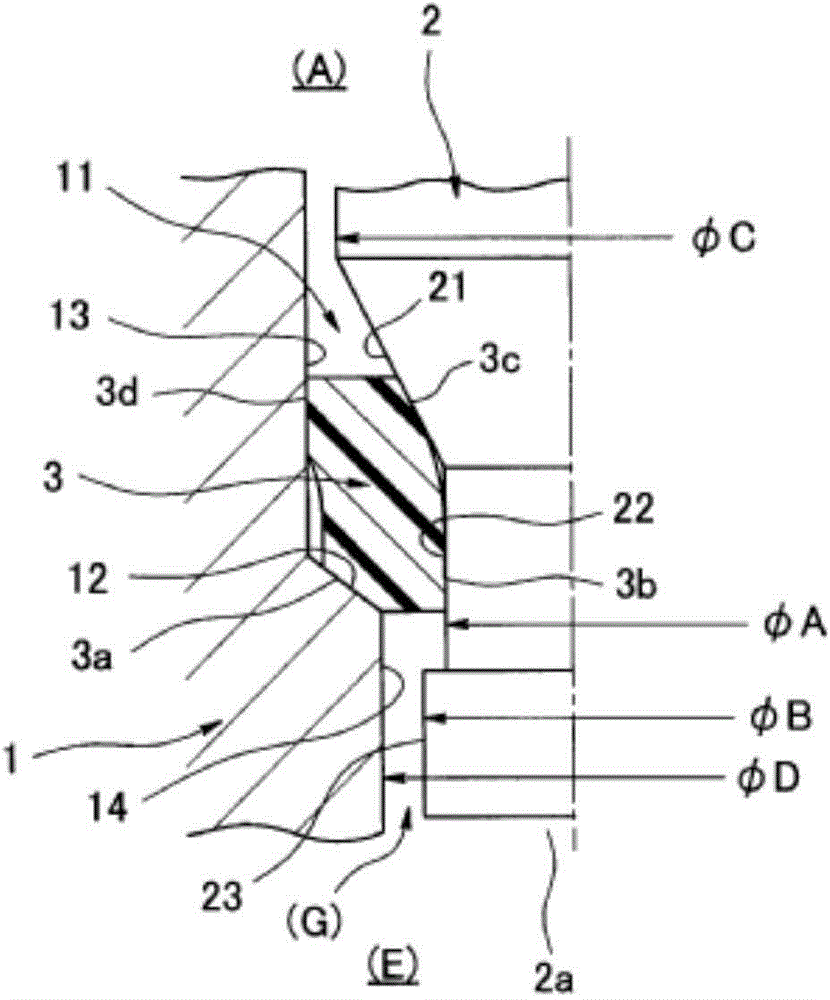

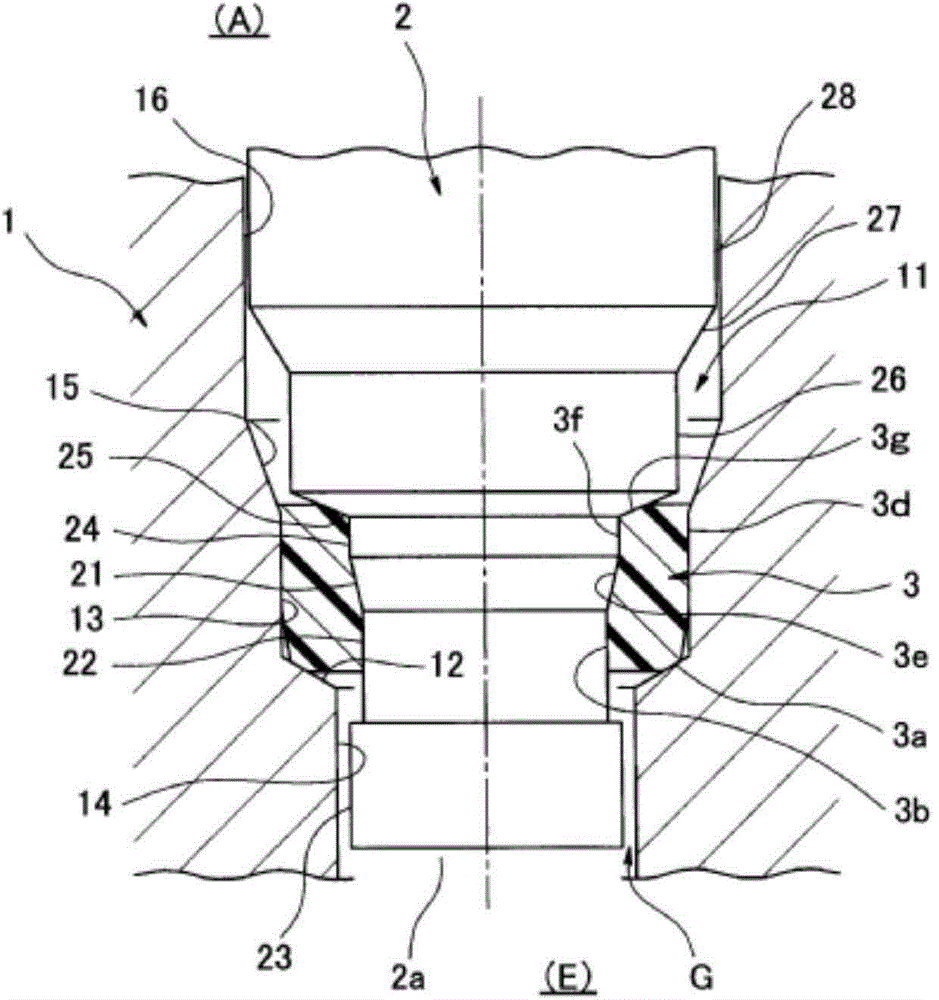

[0066] In addition, after installing the seal ring 3 on the image 3 In the state, first, the seal ring 3 is inserted in advance from the front end side of the nozzle 2a of the injector 2 to the outer peripheral surface 22 of the mounting part. In addition, this is also the same as the first embodiment described above. If the outer diameter ΦA of the mounting portion outer peripheral surface 22 and the outer diameter ΦB of the front end outer peripheral surface 23 have a relationship of 100%<ΦB / ΦA<110%, then The diameter of the seal ring 3 is slightly enlarged when it passes over the front end outer peripheral surface 23 , so residual deformation of the seal ring 3 can be effectively prevented.

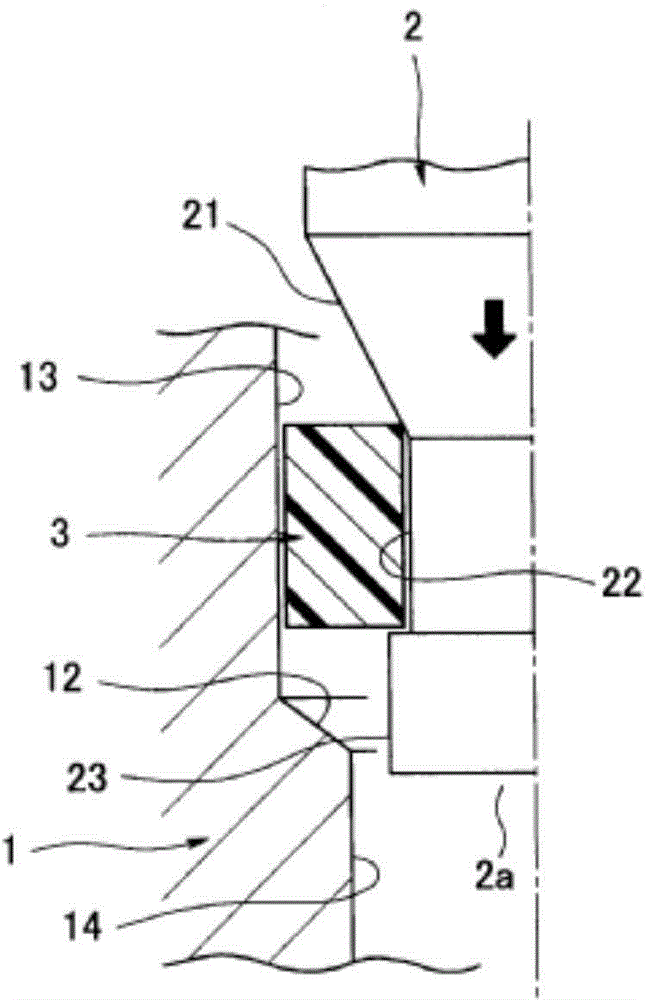

[0067] Next, if Figure 4 As shown in (a), the injector 2 on which the seal ring 3 is inserted is inserted into the injector mounting hole 11 of the cylinder head 1 . Thus, during this insertion, first, if Figure 4 As shown in (b), the end surface outer diameter portion 3 a of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com