A multi-scale, uniform, monodisperse magnetic microsphere and its preparation method

A magnetic microsphere, monodisperse technology, applied in the field of nanocomposite, can solve the problem of difficulty in regulating particles, and achieve the effects of low preparation cost, uniform particles, and easy industrial application and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

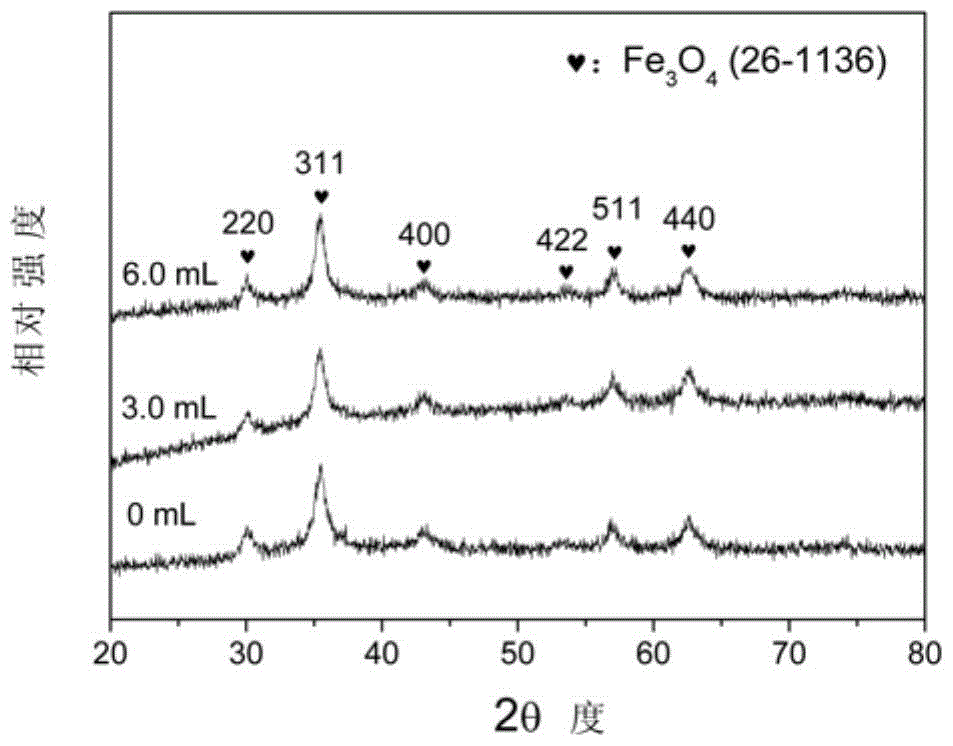

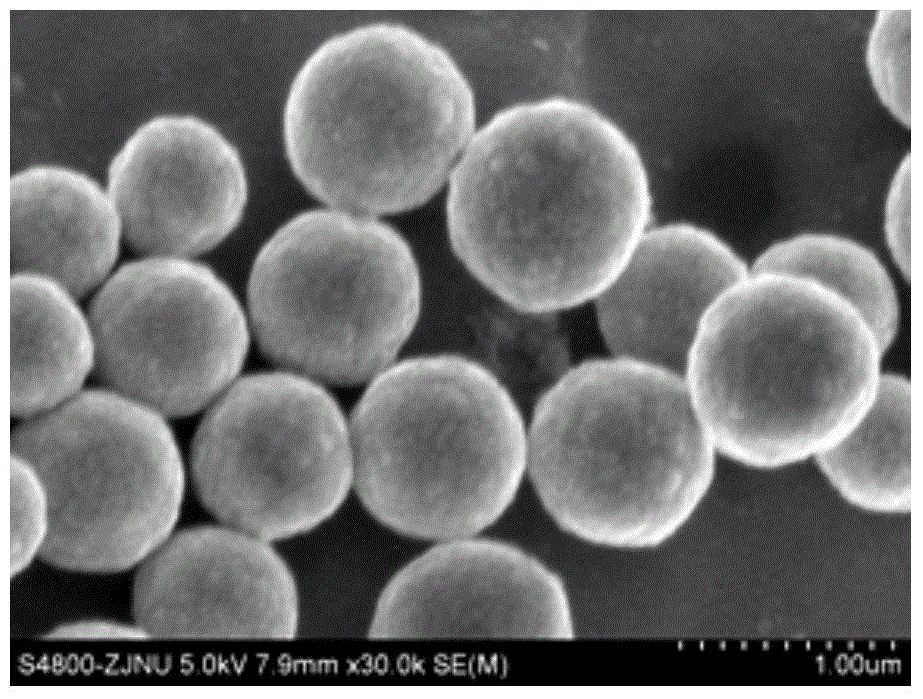

[0043] 3mmol FeCl 3 ·6H 2 O, 20 mL of ethylene glycol, 0.374 g of polyacrylic acid, and 0.69 mL of water were added to the Teflon liner and stirred magnetically for 30 min. Add 12mmol sodium acetate (the ratio of alkali to metal salt is 4) and 20mL ethylene glycol into the beaker and stir for 30 minutes, then transfer to the inner liner and mix for 2.0h. Finally, put the inner liner in a stainless steel kettle and react at 200°C for 12 hours. After cooling, wash by centrifugation (firstly wash with water and ethanol three times respectively, the centrifugal speed is 1500 rpm, and the centrifugation time is 5 minutes each time.), and finally water and ethanol Magnetic separation, separation and washing until the solution is clear, and drying at 60°C for 6 hours to obtain the desired monodisperse magnetic microspheres. The morphology of the obtained product observed under the scanning electron microscope is as follows: image 3 As shown, the average particle size is 904 nm. ...

Embodiment 2

[0045] Same as embodiment 1 step, but FeCl 3 ·6H 2 O is 20mmol, and sodium acetate is 80mmol (alkali and the ratio of the amount of metal salt substance 4), and the appearance that gained product observes under scanning electron microscope is as follows Figure 4 As shown, the average particle size is 1233 nm. The specific surface area of the obtained microspheres is 0.94m 2 g -1 .

Embodiment 3

[0047] Same as embodiment 1 step, but FeCl 3 ·6H 2 O is 30mmol, and sodium acetate is 120mmol (the ratio of the amount of alkali and metal salt substance is 4), and the morphology of the obtained product observed under the scanning electron microscope is as follows Figure 5 As shown, the particle size is not uniform (about 0.5-1.5 μm), and the agglomeration is serious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com