Method for discharging waste gas in radon chamber

A technology of waste gas emission and radon chamber, which is applied in separation methods, chemical instruments and methods, radioactive purification, etc., can solve the problems of limited adsorption of activated carbon, long time-consuming, environmental radioactive pollution, etc., and achieve the goal of easy automation and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The radon chamber exhaust gas discharge method provided by the invention will be further described below in conjunction with the accompanying drawings.

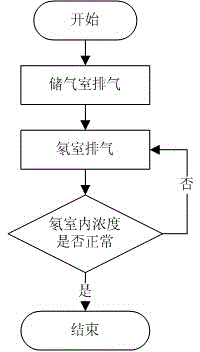

[0026] figure 1 The flow chart of the radon chamber exhaust gas discharge method provided by the present invention is specifically implemented as follows.

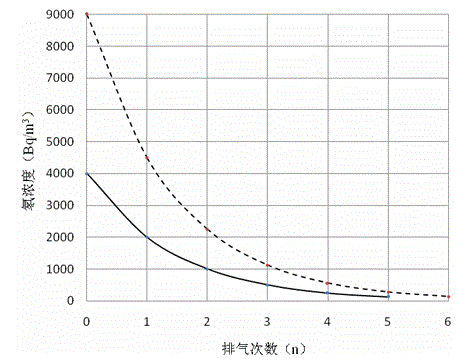

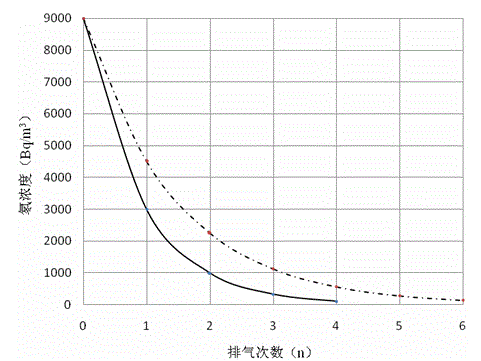

[0027] Step ① When the exhaust gas emission from the radon chamber starts, according to the radon concentration C in the radon chamber Rn0 , the radon concentration C that needs to be achieved in the radon room after the discharge Rn1 , single exhaust volume V from the radon chamber to the gas storage chamber RnO , to calculate the required number of discharges n and the exhaust volume V of the gas storage chamber SO , the specific formula is as follows:

[0028] n = log V Rn - V RnO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com