Display panel and display device

A technology for display panels and display devices, applied to instruments, static electricity, electrical components, etc., can solve the problems of high cost and complex production process, and achieve the effects of low production cost, reduction of production cost, and simplification of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

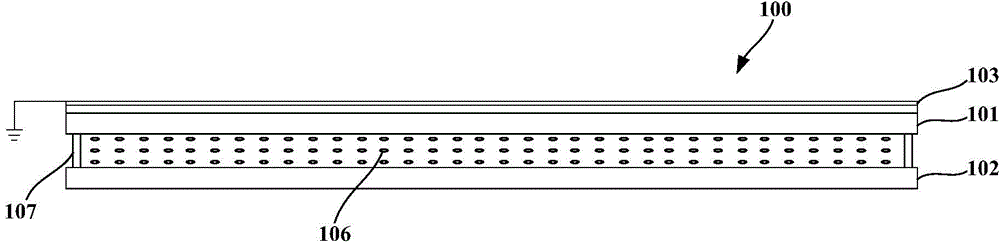

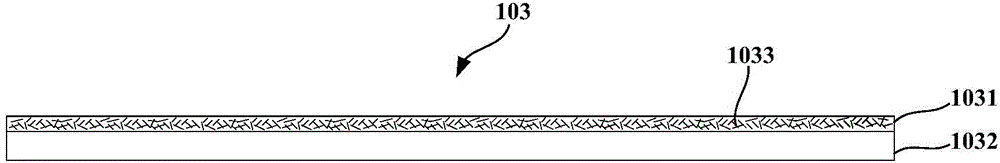

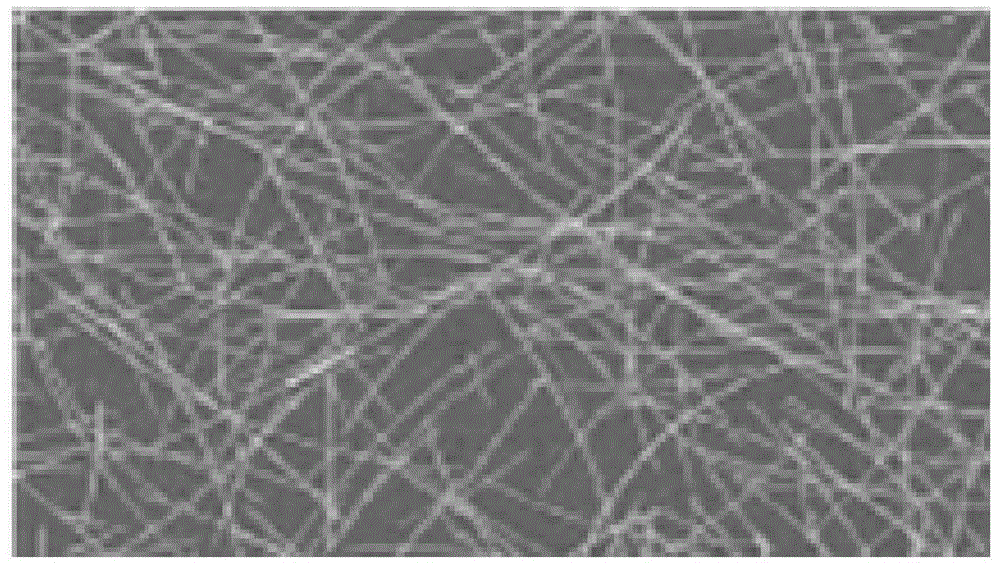

[0041] In order to simplify the production process of the display panel and reduce the production cost while enabling the display panel to have a better anti-static damage effect, embodiments of the present invention provide a display panel and a display device. In the technical solution of the embodiment of the present invention, the display panel includes a conductive layer disposed on the side of the first substrate facing away from the second substrate, the conductive layer is grounded, includes a base layer, and nano conductive materials disposed in the base layer. Since the conductive layer is conductive and grounded, the electrostatic charge on the display panel can be quickly exported to the ground, so that the display panel has a better anti-static damage effect; because the conductive layer is more flexible, it can be directly attached to the The surface of the first substrate facing away from the second substrate, so compared with the prior art, the solution can great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com