Polarization control method used in fiber point-diffraction interferometer wave surface reference source

A point-diffraction interference and polarization control technology, which is applied to optics, instruments, optical components, etc., to avoid blindness and improve the control speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

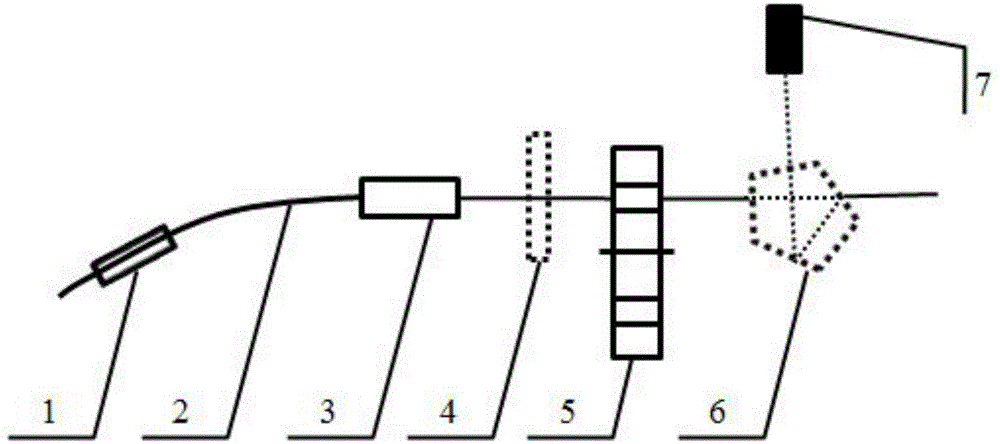

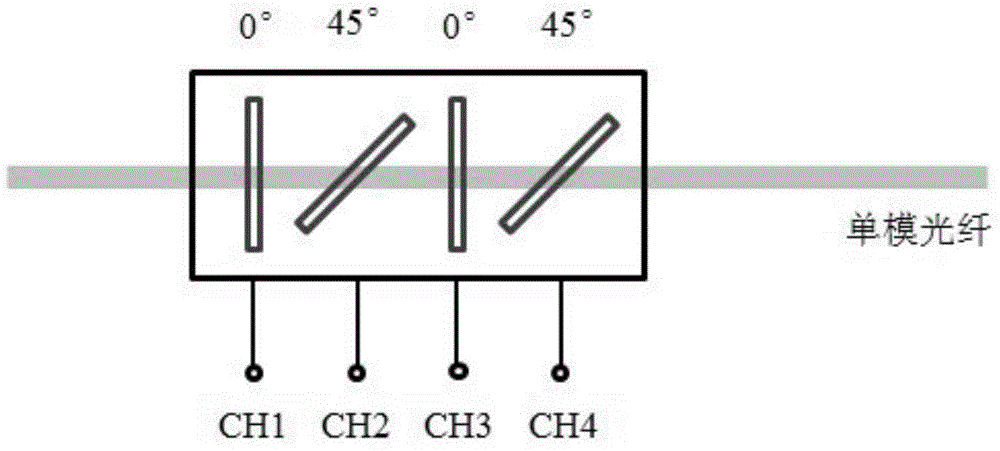

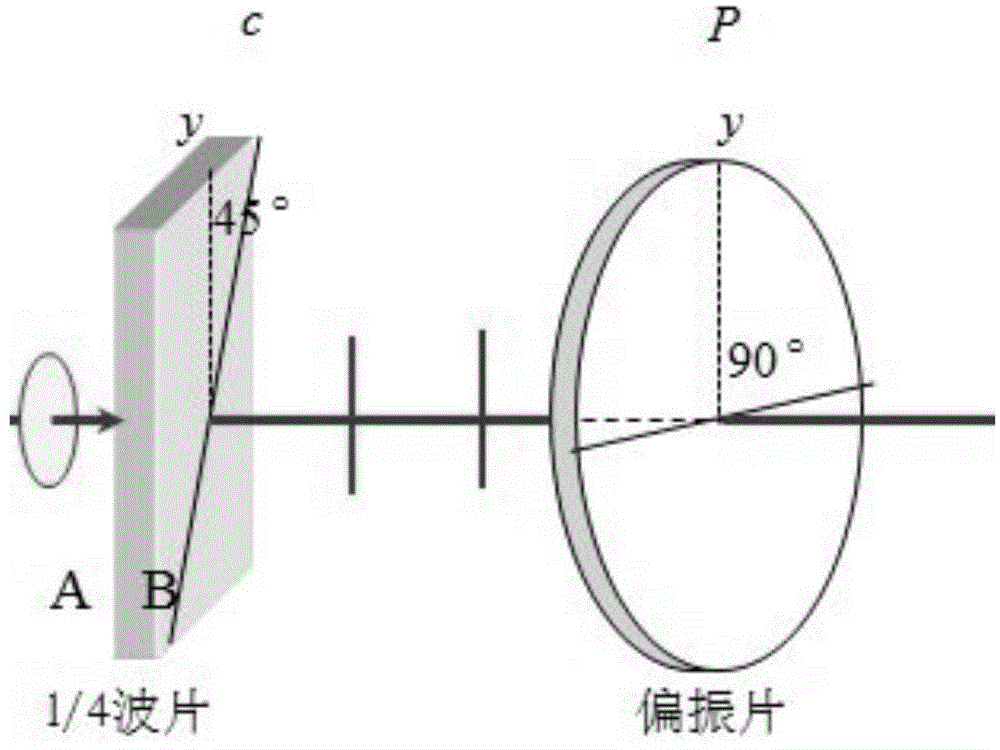

[0025] The inventive idea of the present invention is: the technical idea of the present invention is to change the polarization state of the optical fiber diffracted beam through a polarization controller, and then use a circularly polarized light detection system to detect the polarization state of the beam. The difference is that the polarization state of the initial beam is used Theoretical calculation of the rotating polarizer method, and then calculate the voltage required to control the two channels of the polarization controller to achieve the circular polarization state. On the basis of the fine adjustment of the theoretical calculation, fine-tune the other two control voltages to finally obtain the circular polarization state, and then you can The polarization control system is conveniently moved out of the optical path so no additional errors are introduced.

[0026] Theoretical calculation method:

[0027] Theoretical analysis of the degree of freedom of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com