Profile redesigning method of automobile covering part die based on T spline

A technology for automotive cover and redesign, applied in computing, special data processing applications, instruments, etc., can solve the problem of CAD/CAE being unable to be seamlessly integrated, and achieve the effect of reducing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

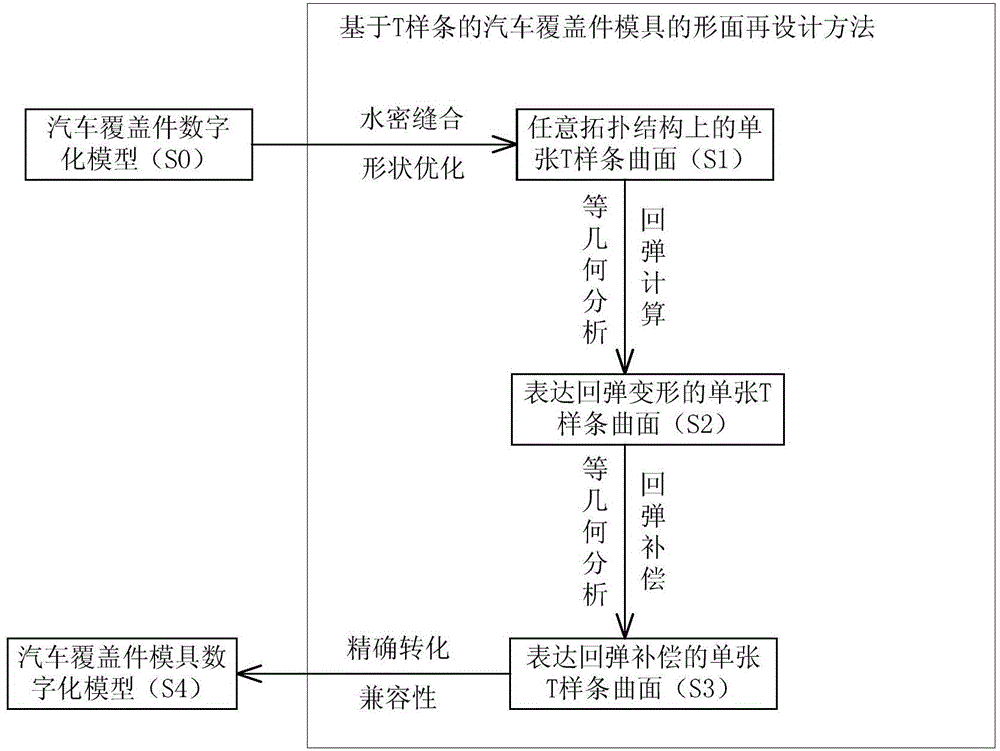

[0018] figure 1 It is a schematic flow chart of the method of the present invention. As shown in the figure, the method consists of 4 steps. Including: step 1), converting the digital model of the car panel (S0) into a single T-spline surface (S1) on any topology structure, this step includes two sub-steps of watertight stitching and character optimization; step 2), using etc. Geometric analysis method is used to obtain a single T-spline surface expressing the springback deformation amount (S2); step 3), and an isogeometric analysis method is used to obtain a single T-spline surface expressing springback compensation (S3); step 4) , convert S3 into a mold surface (S4) for automobile panels compatible with international standards.

[0019] S0 is the design input, S4 is the design output, S1 and S4 are sets of multiple clipped NURBS surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com