Infrared focal plane detector component

A technology of detector components and infrared focal planes, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as correction of complex athermalization means, and achieve the effect of improving adaptability and self-radiation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

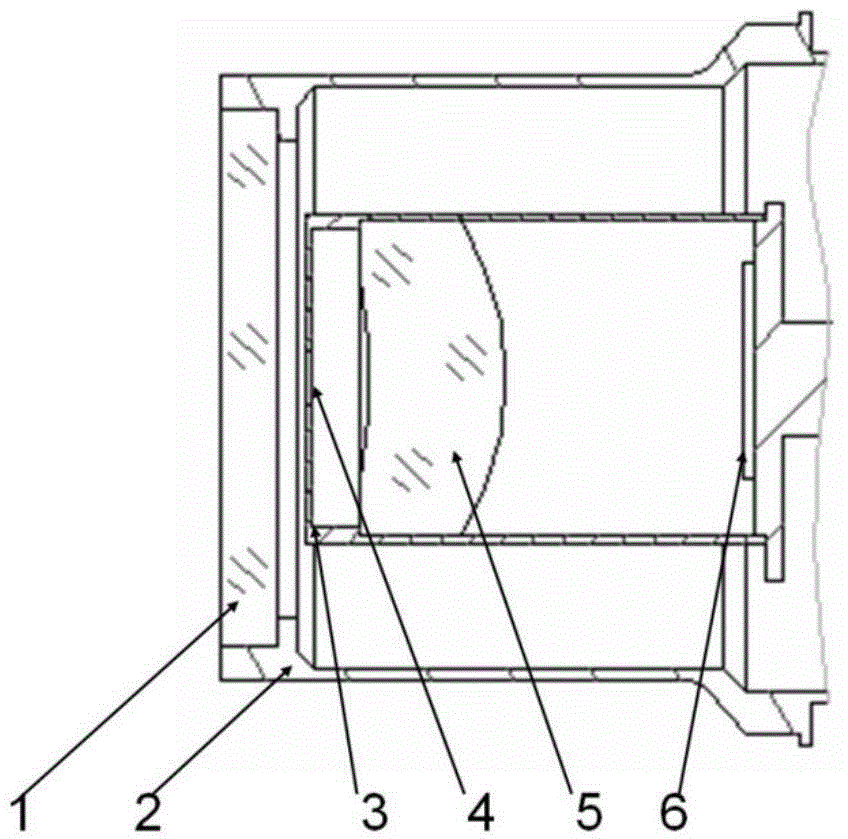

[0023] figure 1 is a schematic structural diagram of an infrared focal plane detector assembly according to Embodiment 1 of the present invention, as figure 1 As shown, the infrared focal plane detector assembly includes: an imaging optical component, a cold screen, and a Dewar, wherein the imaging optical component includes an objective lens and a cold diaphragm, which are integrated inside the above-mentioned Dewar; the objective lens is set as a window of the above-mentioned Dewar, or, The above-mentioned objective lens is glued on the above-mentioned cold screen; the cold diaphragm is arranged on the above-mentioned cold screen; wherein, the above-mentioned cold screen and the above-mentioned window seat of the Dewar are the supporting parts of the above-mentioned imaging optical components.

[0024] There are two implementations for the location of the objective lens, one is that the objective lens is placed on the window of the Dewar, and the other is that the objective ...

Embodiment 2

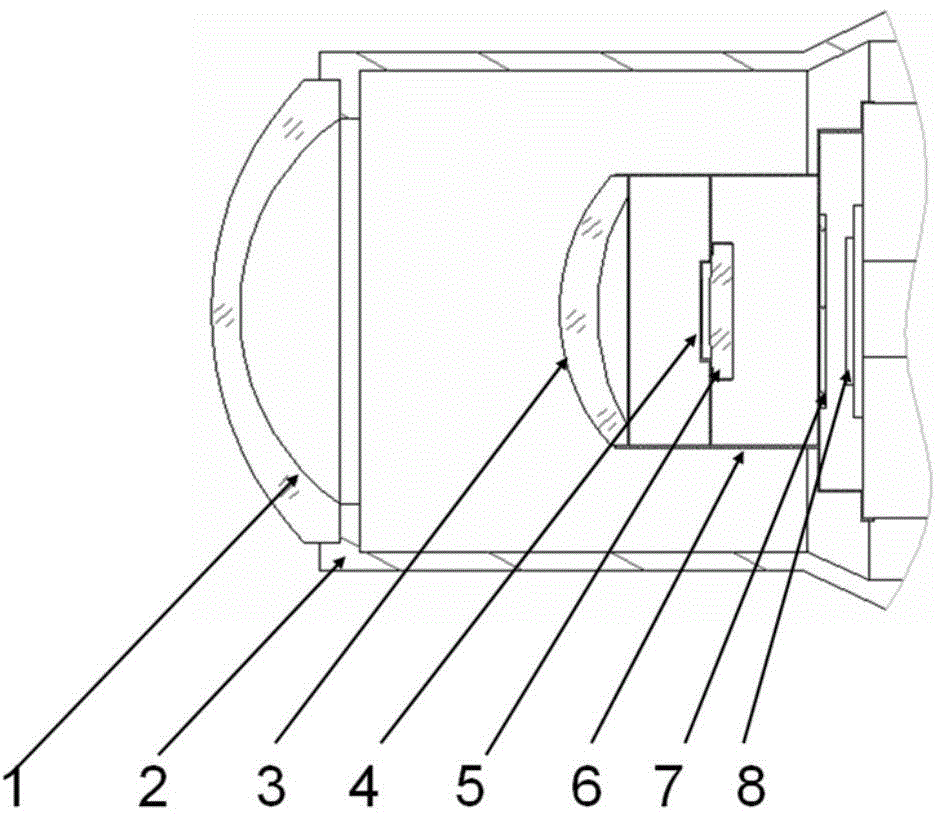

[0035] This embodiment introduces the second implementation manner of the above-mentioned objective lens. figure 2 It is a structural schematic diagram of the infrared focal plane detector assembly of Embodiment 2 of the present invention, as figure 2 As shown, the objective lens includes objective lens 1, objective lens 2, and objective lens 3; the window of Dewar adopts the above-mentioned objective lens 1 to expand the field of view of the optical system; the objective lens 2 and the above-mentioned objective lens 3 are bonded on the cold screen to ensure its correct optical position, and cools the objective lens to a stable temperature by conduction through the aforementioned cold shield. The imaging optical component also includes a low-temperature filter, which is bonded to the above-mentioned cold screen to ensure its correct optical position, and cools the objective lens to a stable temperature through the conduction of the above-mentioned cold screen.

[0036] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com