A temperature difference control structure for energy-saving kilns

A technology of temperature difference control and kiln, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve problems such as cracking, waste products, product deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific embodiment:

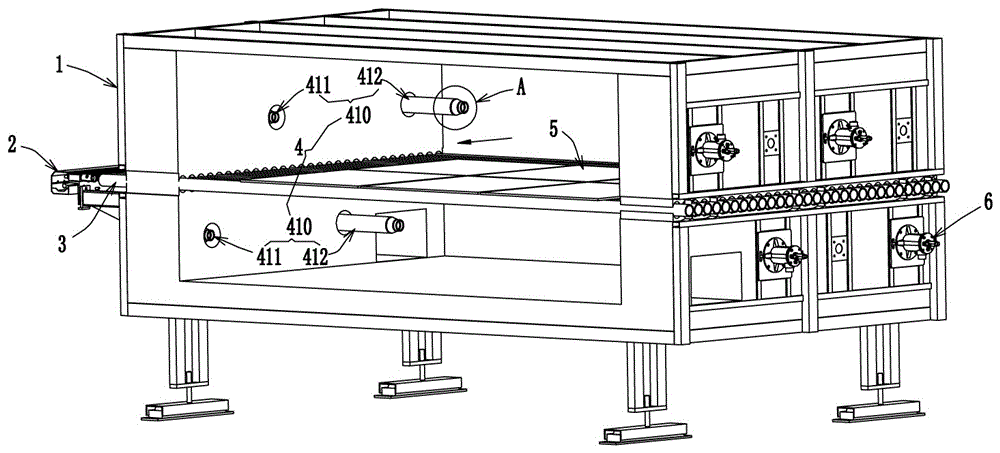

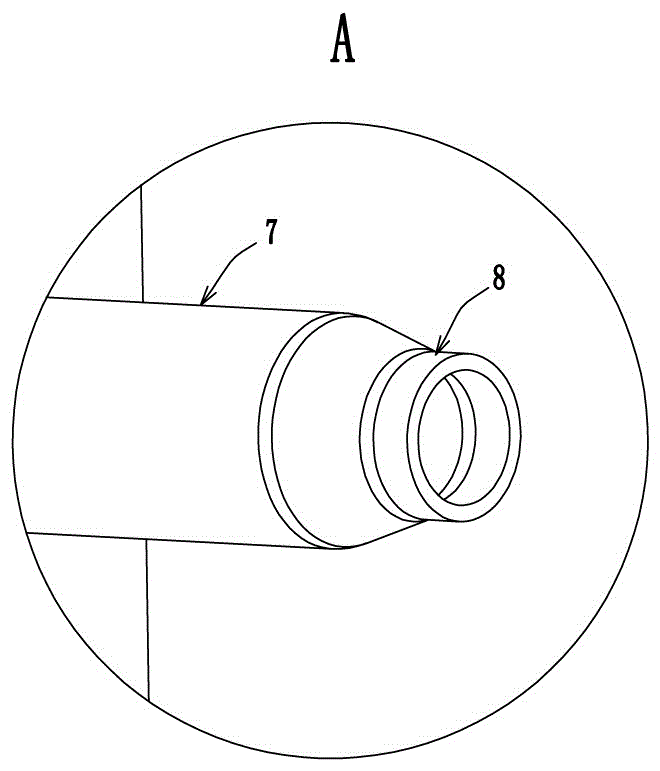

[0010] See attached figure 1 As shown, a temperature difference control structure for firing equipment described in this embodiment, the new temperature difference control structure includes a kiln frame 1, a roller conveying assembly 3 installed on the kiln frame 1, for driving The transmission mechanism 2 for the rotation of the roller conveying assembly 3, multiple sets of combustion splitter assemblies 4 symmetrically installed on both sides of the kiln frame and arranged along the conveying direction of the roller conveying assembly 3, and used to provide the combustion splitter assembly 4 Burner 6 for heat. Each set of combustion splitter assembly 4 includes a pair of combustion splitter groups 410 respectively installed on the upper and lower sides of the roller conveying assembly 3, wherein each combustion splitter group 410 also includes a combustion divider group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com