Countercurrent plate type dew-point indirect evaporative cooler with internal dividing structure, and channel clapboard

An evaporative cooler and dew point indirect technology, which is applied in the field of counter-flow plate coolers and dew point indirect evaporative coolers, can solve the problems of poor hydrophilic effect, single performance, and unfavorable heat transfer due to the thickness of channel baffles, and achieves increased efficiency. High sensible heat exchange efficiency, saving power consumption and good air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

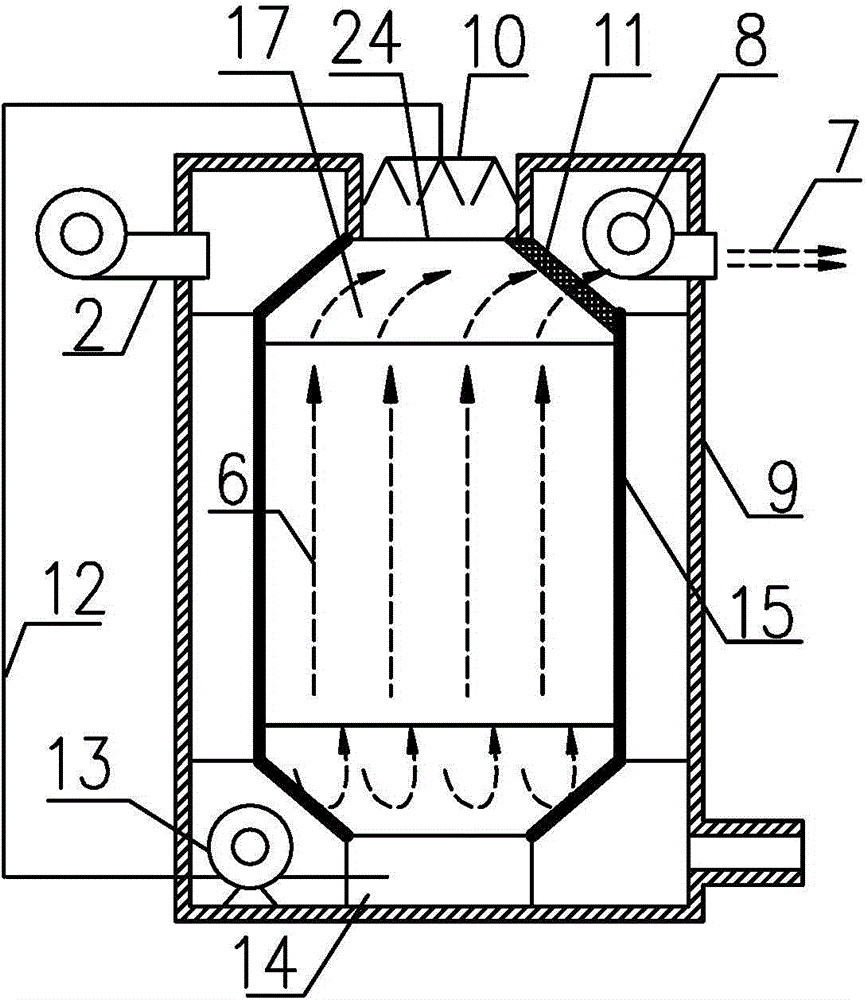

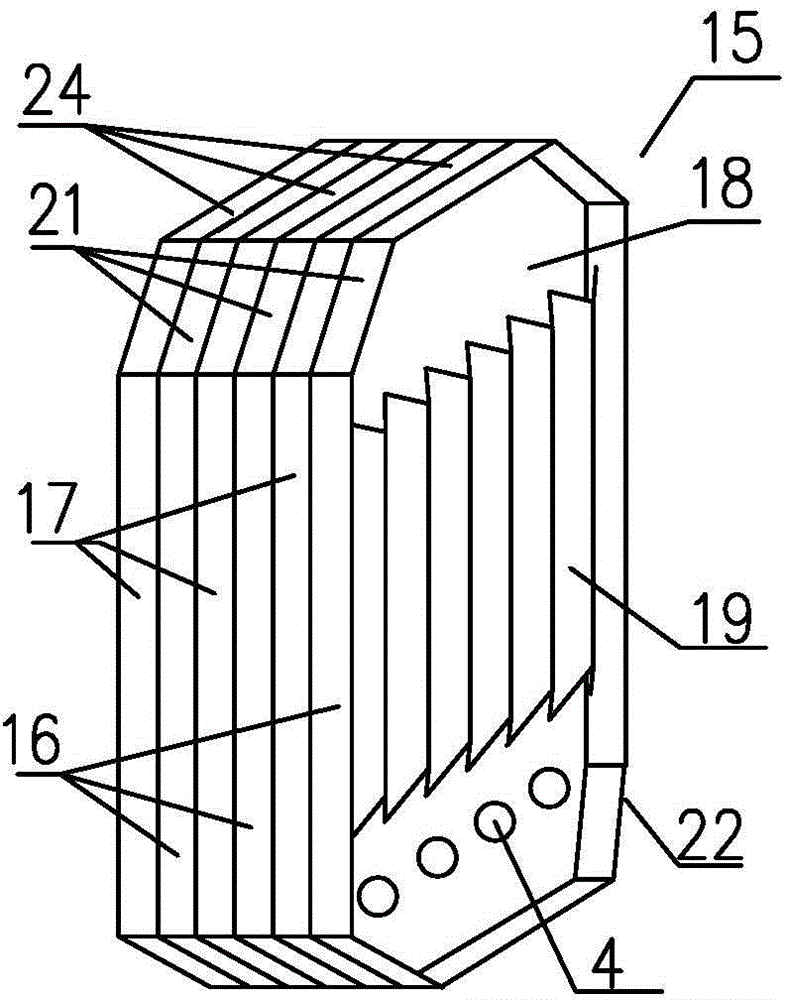

[0023] like figure 1 and figure 2 As shown, the present invention proposes a counterflow plate dew-point indirect evaporative cooler with a built-in flow splitting structure, including a casing 9 and a dew-point indirect evaporative cooler core 15 disposed in the casing 9 .

[0024] The top of the casing 9 is provided with an air inlet 1, a secondary air outlet 7 and a water distributor 10, and the bottom of the casing 9 is provided with an upper opening type water collection tank 14, a circulating water pump 13 and a primary air supply outlet 5 , the air inlet 1 is provided with a blower 2 connected by an air pipe, the secondary air outlet 7 is provided with an exhaust fan 8 connected by an air pipe, and the secondary air outlet 7 communicates with the outdoor , the primary air 3 is cooled and led to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com