A water-lubricated tilting pad hydrostatic bearing structure cooled by return water tank

A hydrostatic bearing and water return tank technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of hydrostatic bearing heating, instability, oil film oscillation, etc., achieve good stability, solve serious heating, temperature The effect of raising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

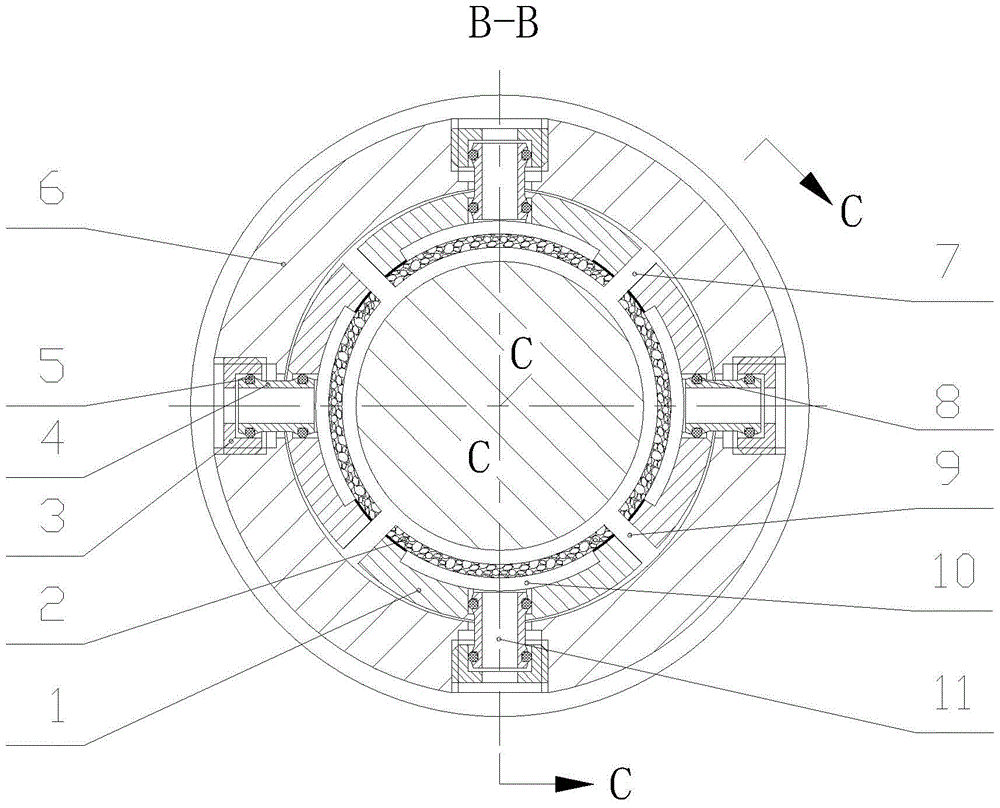

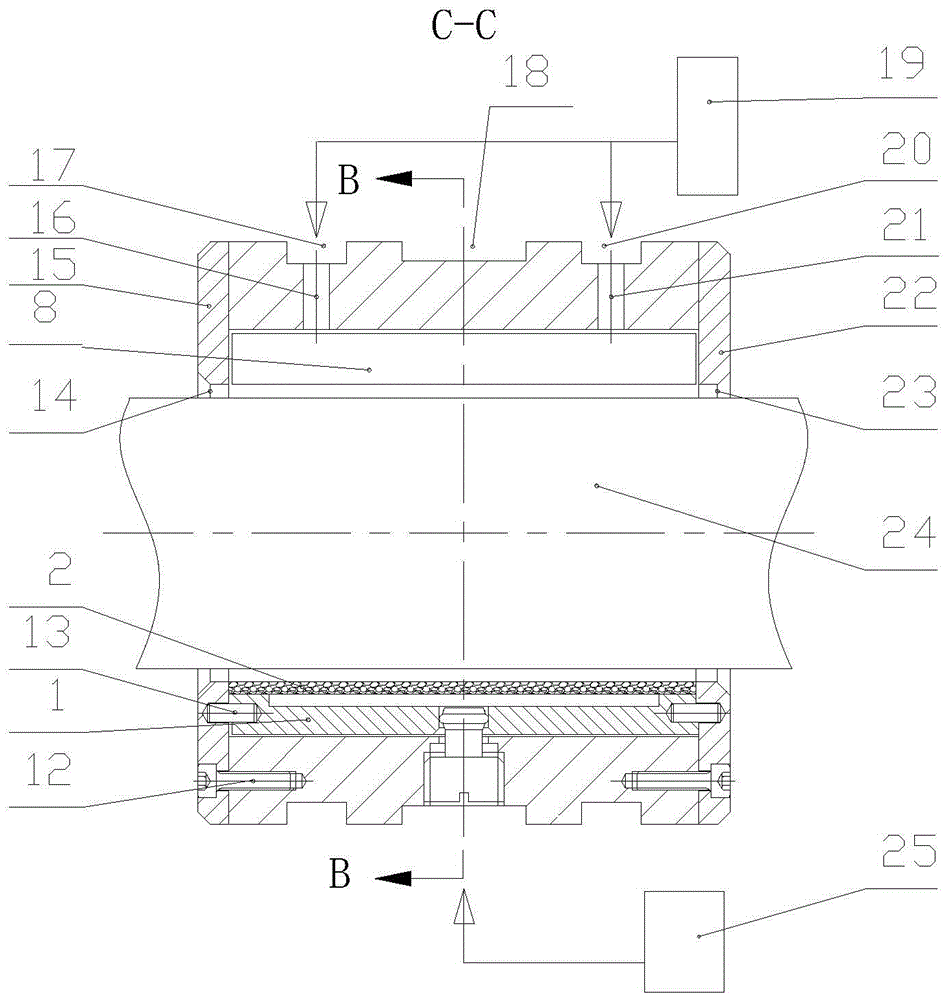

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 and 2 Shown: a water-lubricated tilting pad hydrostatic bearing structure cooled by a return water tank, including a stainless steel outer tile 1, a static pressure inner tile 2, a screw sleeve 3, a hollow pin 4, a sealing ring 5 and a sealing ring 8, Bearing seat 6, compression screw 12, positioning pin 13, low-pressure water pump 19 and high-pressure water pump 25. The outer cylindrical surface of the bearing pad seat is provided with a high-pressure annular water supply groove 18 and a low-pressure annular water supply groove 17 and 20 . The external high-pressure water pump 25 and the low-pressure water pump 19 are communicated respectively.

[0014] The static pressure inner tile 2 adopts porous ceramics (SiC, SiO 2 etc.), the stainless steel outer tile 1 is made of austenitic stainless steel 0Cr18Ni9 material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com