Fastening structure suitable for movable floating nuclear power plant platforms

A technology for fastening structures and nuclear power plants. It is used in threaded fasteners, locking fasteners, connecting components, etc. It can solve the problems of bolt fatigue and aging, affecting fixing conditions, platform vibration, etc., so as to reduce the possibility of loosening and contact The effect of increasing the area and increasing the force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

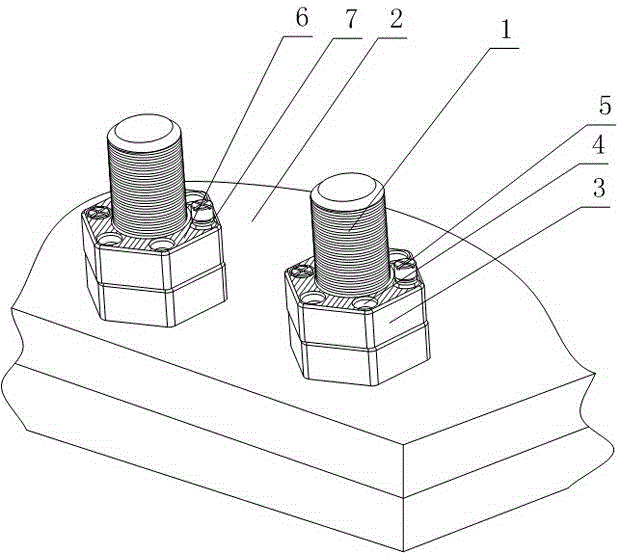

[0020] Such as figure 1 The schematic diagram shown is a fastening structure suitable for a movable floating nuclear power plant platform, including a bolt column body 1, a platform 2 connected through the bolt column body 1, and two nuts 3 matching the bolt column body 1 , six small bolt holes 4 are evenly arranged on the nut 3, and two adjacent nuts 3 are connected by installing small bolts 5 in the small bolt holes 4; common hexagonal or octagonal nuts 3 are used, and each Angle, set corresponding small bolt hole 4 according to certain specification, be used to install small bolt 5, generally hexagonal bolt can install six small fastening bolts, eight side bolt can install eight small fastening bolts; The top of the head bolt is provided with a "ten" notch or a "one" notch; the rotation direction of the bolt column body 1 is opposite to that of the small bolt 5, and the upper and lower ends of the nut 3 are provided with multiple anti-slip The groove 6; the small bolt 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com