Combustion parameter adjusting method and combustion parameter adjusting device of supercharged engine

A supercharged engine and combustion parameter technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as poor exhaust gas treatment effect of supercharged engines, long catalytic converter light-off time, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

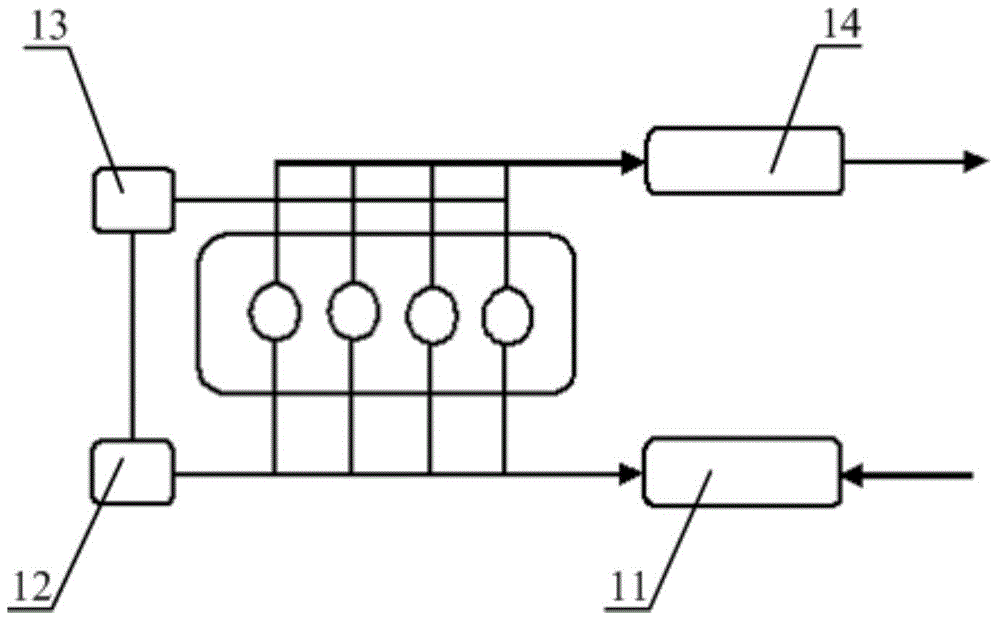

[0045] Such as figure 1 As shown, in the secondary air injection system, fresh air is introduced into the exhaust pipe of the automobile through the air filter 11, the secondary air pump 12 and the secondary air valve 13, that is, it is introduced at a position as close as possible to the exhaust valve. Fresh air, so that the fresh air is mixed with the exhaust gases from the engine in the exhaust pipe. The fresh air rich in oxygen will oxidize HC (hydrocarbons) and CO (carbon monoxide) in the exhaust gas, and release heat at the same time, so that the catalytic converter 14 behind starts to work in a short time after the car is started. In turn, the exhaust gas can be processed faster, and the pollution caused by exhaust gas emission to the env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com