A scroll variable cylinder methanol engine

A methanol engine and scroll technology, which is applied to engine components, engine cooling, machines/engines, etc., can solve the problems of not fully utilizing the advantages of methanol energy, facing the oil crisis, and operating vibrations, etc. Ratio and economy, improve starting performance, reduce PM2.5 effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

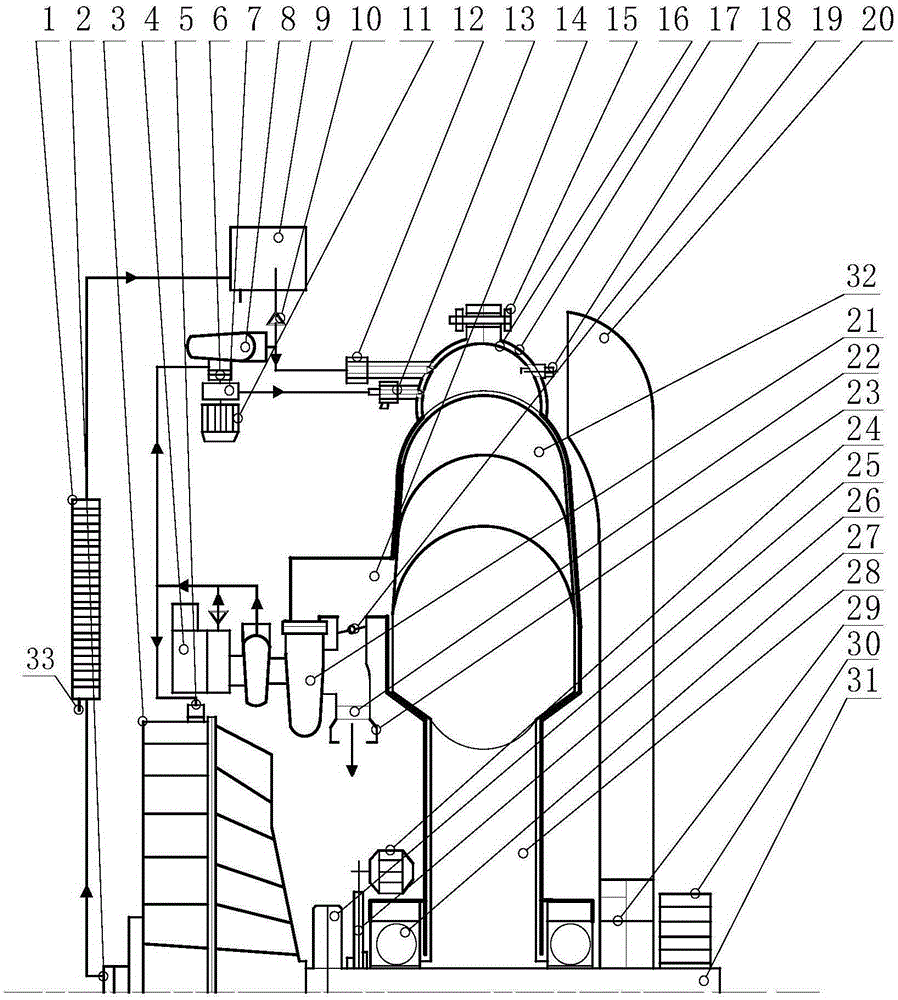

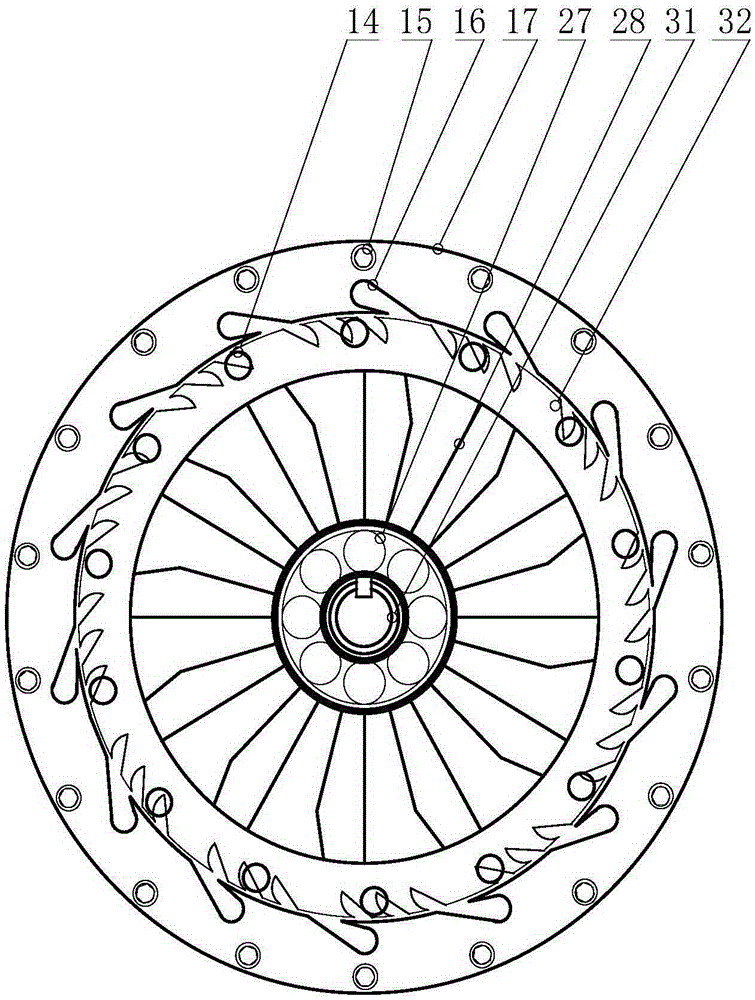

[0016] The specific implementation manners in the present invention will be further described below in conjunction with the accompanying drawings.

[0017] figure 1 , figure 2 Medium, including intercooler 1, scroll air compressor output 2, scroll compressor 3, air filter 4, scroll compressor inlet 5, spare air supply machine clutch 6, high-pressure methanol pump 7, and spare air supply machine 8. Air bag 9, one-way valve 10, dual-purpose motor 11, air supply nozzle 12, high-pressure methanol nozzle 13, exhaust pipe 14, engine casing combination screw 15, combustion injection chamber 16, engine casing 17, igniter 18. Exhaust bypass 19, combustion chamber cooling vane 20, turbocharger 21, exhaust processor 22, exhaust pipe 23, starter motor 24, turbo compressor clutch 25, starter wheel 26, oil-free bearing 27, main engine Self-cooling wind wheel 28, blade clutch 29, power output wheel 30, main shaft 31, impeller 32, steam trap 33, etc.

[0018] Such as figure 1 , figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com