A liquefied fuel engine

An engine and fuel technology, used in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of laborious operation and weight concentration, and achieve the effect of improving safety performance, weight concentration, and maintaining work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

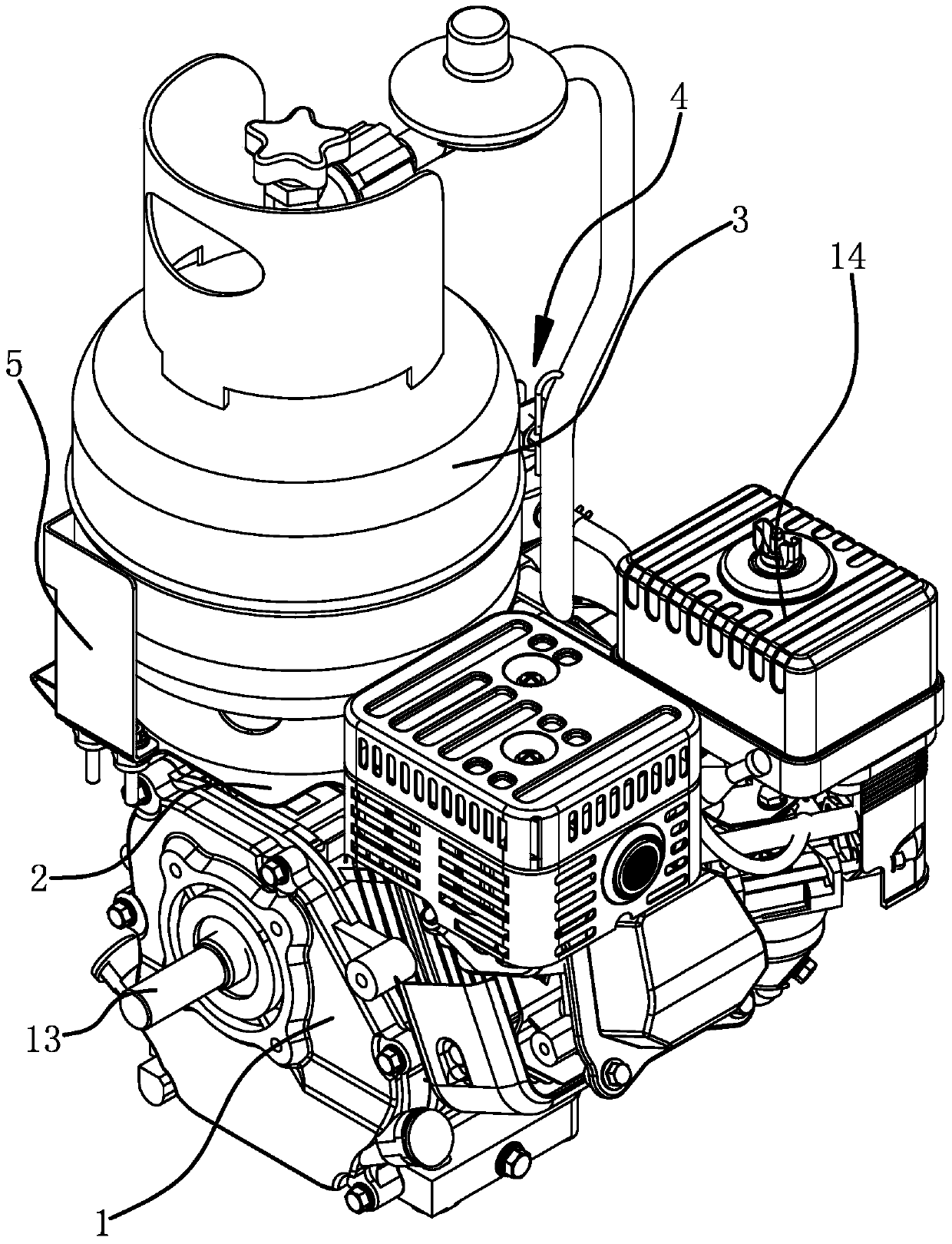

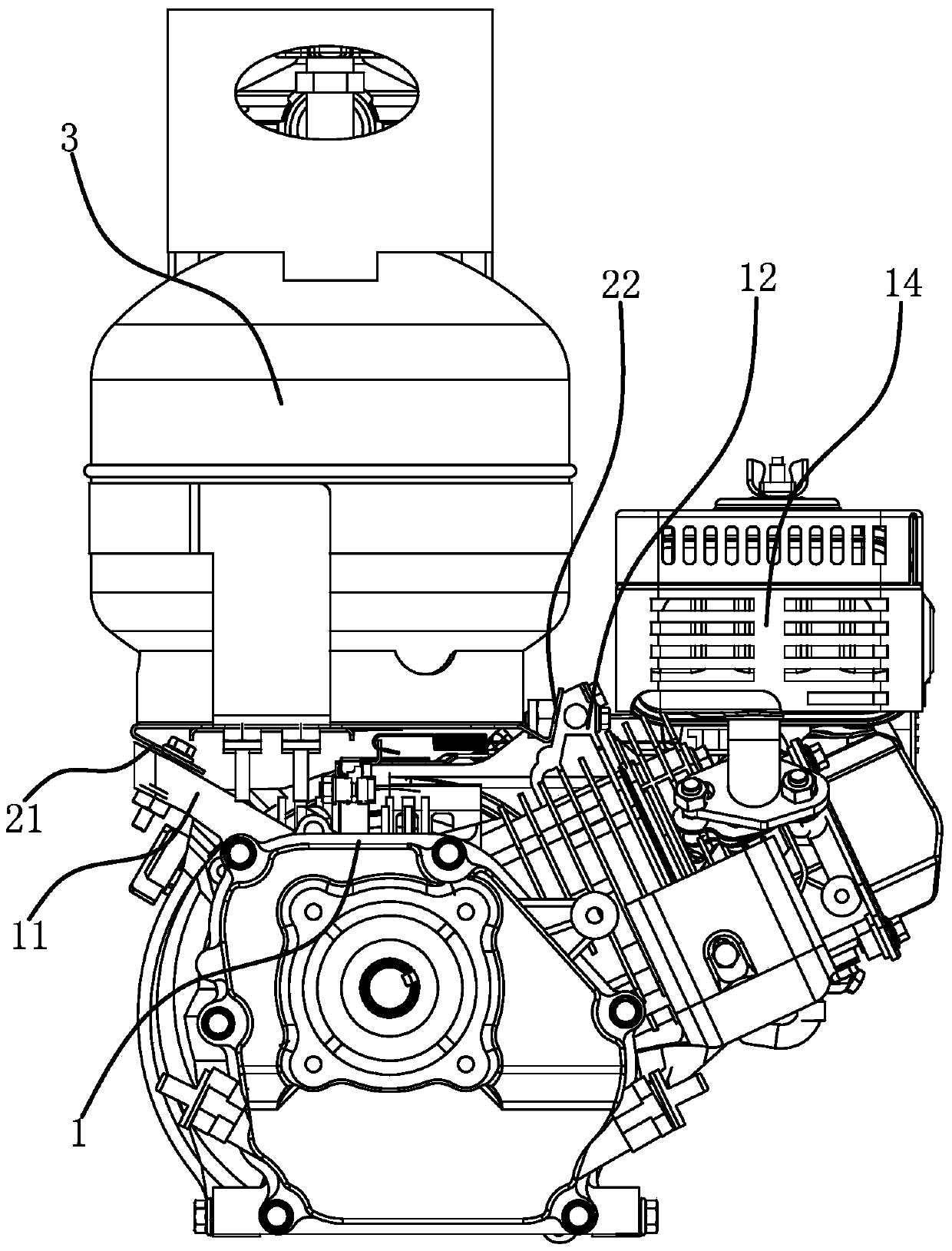

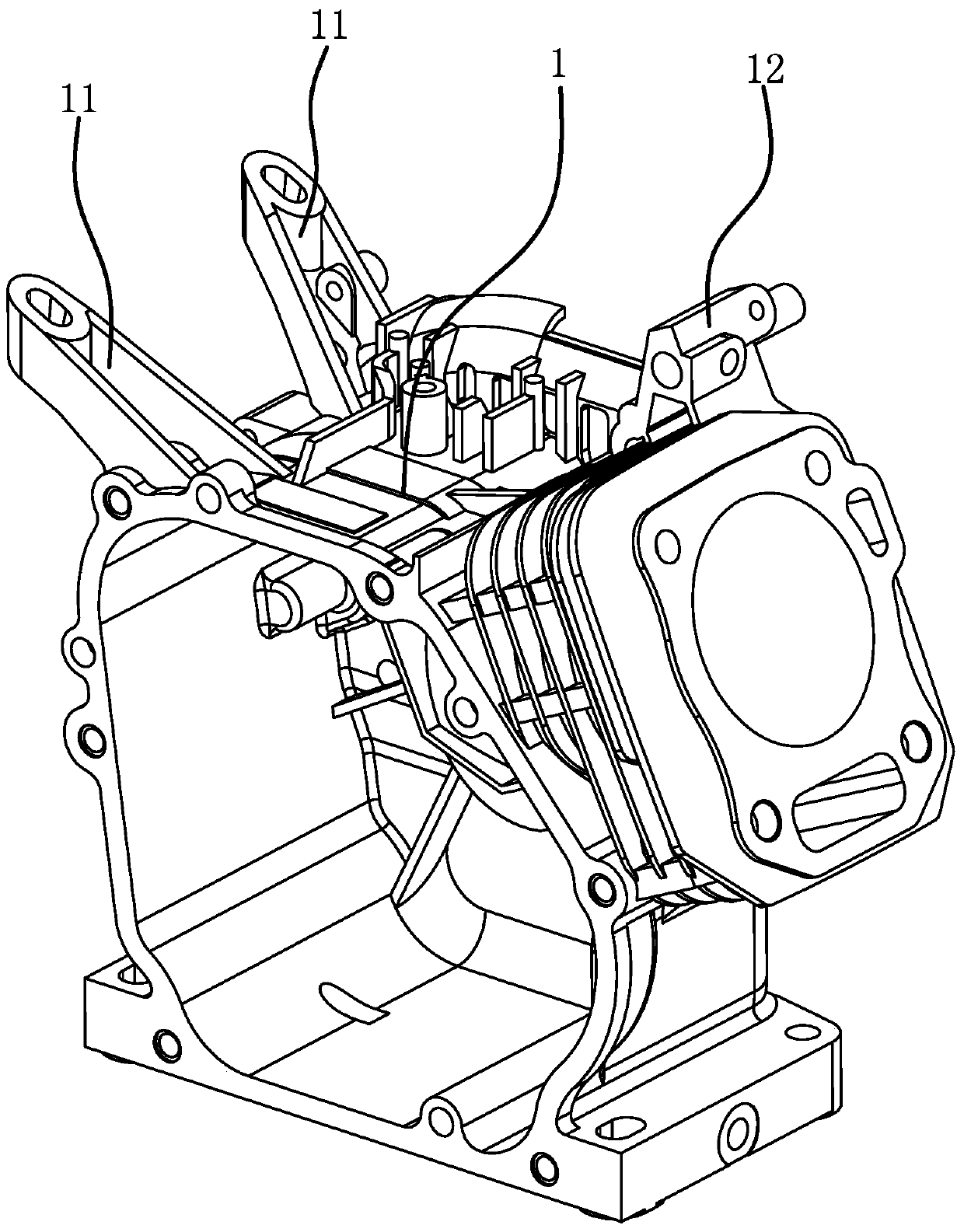

[0022] Such as figure 1 As shown, a liquefied fuel engine includes a crankcase 1, a plate-shaped base 2 and a liquefied gas tank 3, the crankcase 1 includes a crank chamber and a combustion chamber, the crank chamber is provided with a crankshaft, and the crankshaft is connected to an output shaft 13, A muffler 14 is fixedly connected on the outer wall of the crankcase 1, and the edge of the base 2 is fixedly connected with the crankcase 1. The base 2 is located above the output shaft 13, and the muffler 14 is located on one side of the base 2, and the upper side of the base 2 Keep it horizontal, and there is a gap between the lower side of the base 2 and the outer side wall of the crankcase 1, the liquefied gas tank 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com