3D printing internal parting wall and construction method of 3D printing internal parting wall

A 3D printing and construction method technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of wasting materials, unable to meet the requirements of wall construction with special-shaped architectural shapes, etc., achieving less on-site operations, saving labor and materials, and improving The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

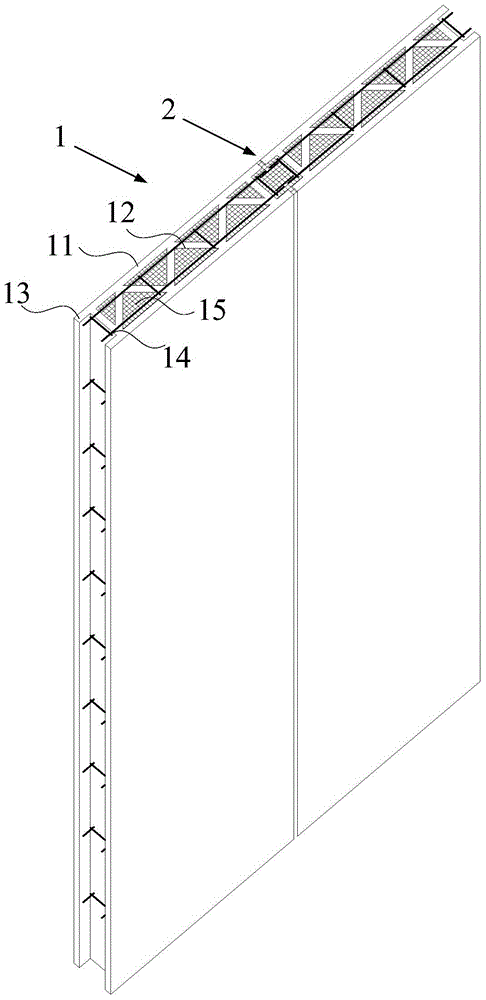

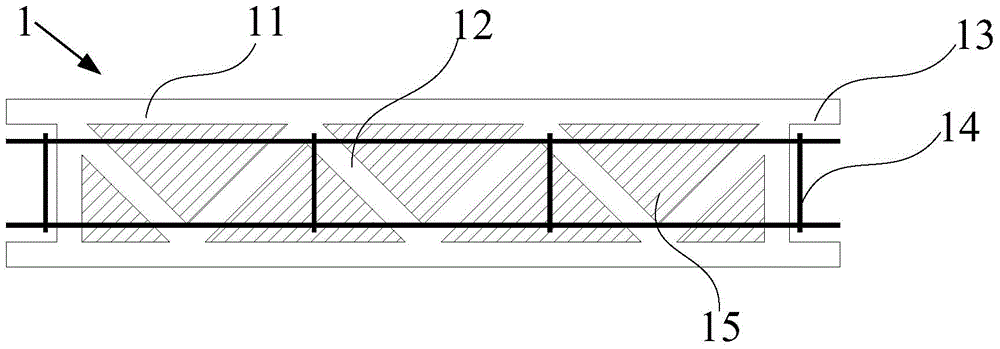

[0041] refer to figure 1 , shows a schematic diagram of the structure of the 3D printed inner partition wall of the present invention. refer to figure 2 , shows a cross-sectional view of the 3D printed inner partition wall of the present invention. combine figure 1 and figure 2 As shown, the 3D printed inner partition wall of the present invention includes: a prefabricated inner partition wall unit 1, fillers and steel mesh sheets.

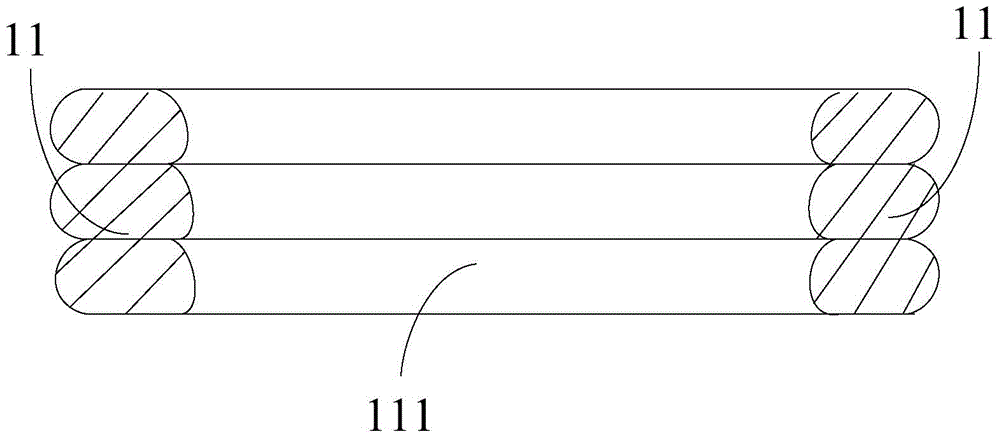

[0042] A plurality of prefabricated inner partition wall units 1 formed by 3D printing technology arranged side by side, the prefabricated inner partition wall unit 1 includes: two outer wall panels 11 arranged parallel to each other, and inner flaps 12 arranged between the outer wall panels 11 ; Wherein: the outer wall panels 11 are separated by inner folded plates 12 to form a plurality of truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com