Refining agent for continuous dyeing

A technology of refining agent and long car, which is applied in the field of refining agent for long car printing and dyeing, can solve the problems of insufficient liquid carrying capacity, affecting the refining process, poor ability to penetrate into the core of the fabric, etc., and achieves excellent low temperature flow performance and good penetration ability. , the effect of fast production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A refining agent for printing and dyeing of long cars, comprising the following components, and the mass ratio of each component is: 5 parts of sodium secondary alkyl sulfonate, 10 parts of (isomeric) fatty alcohol polyoxyethylene ether phosphate, isomeric fatty alcohol 5 parts of polyoxyethylene propylene ether, 5 parts of chelating dispersant, 1 part of caustic soda, 74 parts of deionized water.

[0018] Mix and stir the above-mentioned raw materials evenly.

Embodiment 2

[0020] A refining agent for printing and dyeing of long cars, comprising the following components, and the mass ratio of each component is: 10 parts of sodium secondary alkyl sulfonate, 20 parts of (isomeric) fatty alcohol polyoxyethylene ether phosphate, isomeric fatty alcohol 7 parts of polyoxyethylene propylene ether, 5 parts of chelating dispersant, 3 parts of caustic soda, 55 parts of deionized water.

[0021] Mix and stir the above-mentioned raw materials evenly.

Embodiment 3

[0023] A refining agent for printing and dyeing of long cars, comprising the following components, and the mass ratio of each component is: 20 parts of secondary alkyl sodium sulfonate, 40 parts of (isomeric) fatty alcohol polyoxyethylene ether phosphate, isomeric fatty alcohol 10 parts of polyoxyethylene propylene ether, 10 parts of chelating dispersant, 5 parts of caustic soda, 15 parts of deionized water.

[0024] Mix and stir the above-mentioned raw materials evenly.

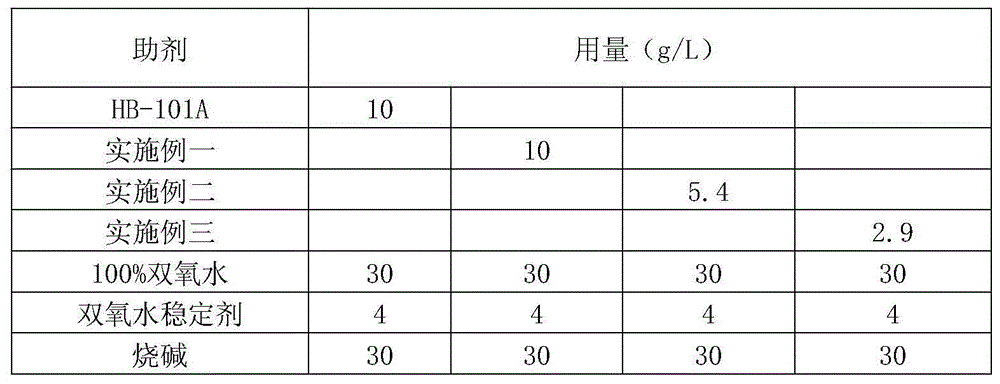

[0025] Because the effective content of secondary alkyl sodium sulfonate is 60%, the effective content of chelating dispersant is 20%, so the effective content of above-mentioned embodiment is: embodiment one is 20%, embodiment two is 37%, embodiment two Three is 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com