Negative ion functional ink as well as preparation method and production method thereof

A negative ion and functional technology, applied in the field of negative ion functional ink and its preparation, can solve the problems of large amount of negative ions added, glaze defects and high production cost, and achieve the effects of low preparation cost, good dispersibility and saving of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

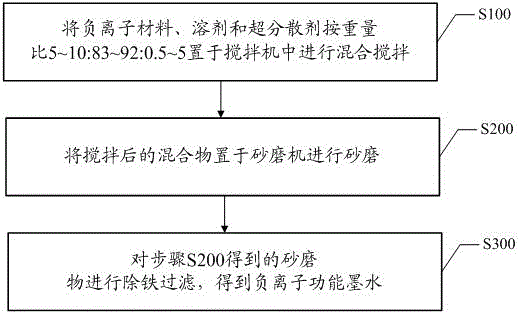

Method used

Image

Examples

Embodiment 1

[0070] The negative ion material tourmaline, solvent white mineral oil, and hyperdispersant polymethyl acrylate are mixed and stirred according to the weight ratio of 8:90:2, the stirring time is 1h, the speed is 200r / min, and the stirring equipment is a basket mixer . The mixture after the stirring is completed enters the sand mill for sand milling, the sand milling efficiency is 5Kg / h, the rotating speed is 1300r / min, and the stirring equipment is a 30L horizontal sand mill. After sanding to a fineness of D10>0.05μm, D90 of 0.3±0.05μm, and D100<1μm, use a filter with a pore size of ≤1μm for iron removal and filtration under vacuum conditions. After the filtration is completed, nano-scale high-volume negative ion functional ink is obtained.

Embodiment 2

[0072] Mix and stir the negative ion materials medical stone, strange ice stone, solvent isopropyl biphenyl, and hyperdispersant polyethylacrylate according to the weight ratio of 5:5:86:4. The stirring time is 1h and the rotation speed is 200r / min, the mixing equipment is a basket mixer. The mixture after the stirring is completed enters the sand mill for sand milling, the sand milling efficiency is 5Kg / h, the rotating speed is 1300r / min, and the stirring equipment is a 30L horizontal sand mill. After sanding to a fineness of D10>0.05μm, D90 of 0.3±0.05μm, and D100<1μm, use a filter with a pore size of ≤1μm for iron removal and filtration under vacuum conditions. After the filtration is completed, nano-scale high-volume negative ion functional ink is obtained.

Embodiment 3

[0074] The negative ion material opal, wizard stone, hornblende, solvent white mineral oil, solvent isopropyl biphenyl, hyperdispersant polydodecyl acrylate are according to the weight ratio of 2:2:2:45:45:4 Mix and stir by weighing, the stirring time is 1h, the rotating speed is 200r / min, and the stirring equipment is a basket mixer. The mixture after the stirring is completed enters the sand mill for sand milling, the sand milling efficiency is 5Kg / h, the rotating speed is 1300r / min, and the stirring equipment is a 30L horizontal sand mill. After sanding to a fineness of D10>0.05μm, D90 of 0.3±0.05μm, and D100<1μm, use a filter with a pore size of ≤1μm for iron removal and filtration under vacuum conditions. After the filtration is completed, nano-scale high-volume negative ion functional ink is obtained.

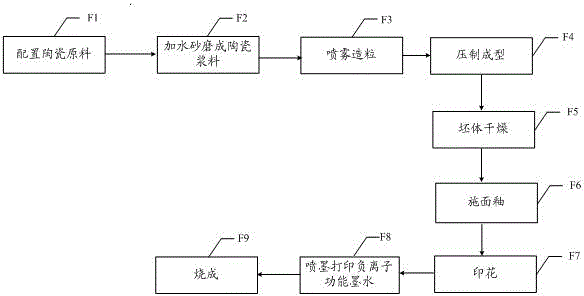

[0075] Production of negative ion functional ceramic tiles:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com