Ester-containing quaternary ammonium salt modified montmorillonite and preparation method thereof

The technology of ester quaternary ammonium salt and montmorillonite is applied in the direction of fibrous filler, dyed low-molecular-weight organic compound treatment, etc., can solve the problems of high reaction temperature, single modification effect, complicated method, etc., and achieves simple preparation method, The effect of improving compatibility and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method step of present embodiment containing ester group quaternary ammonium salt modified montmorillonite is as follows:

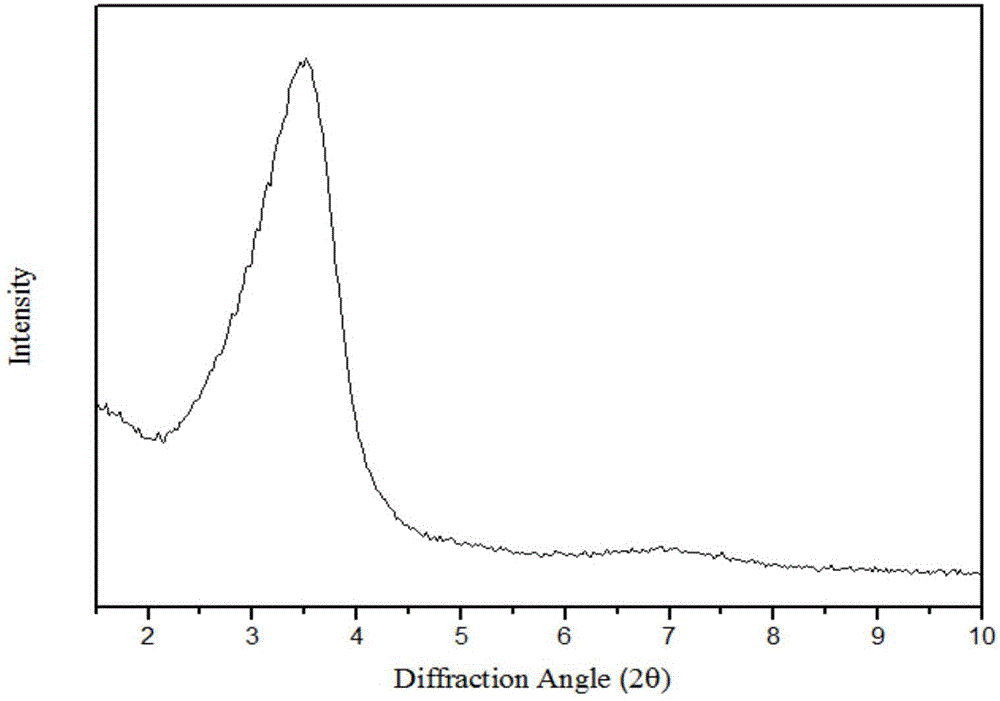

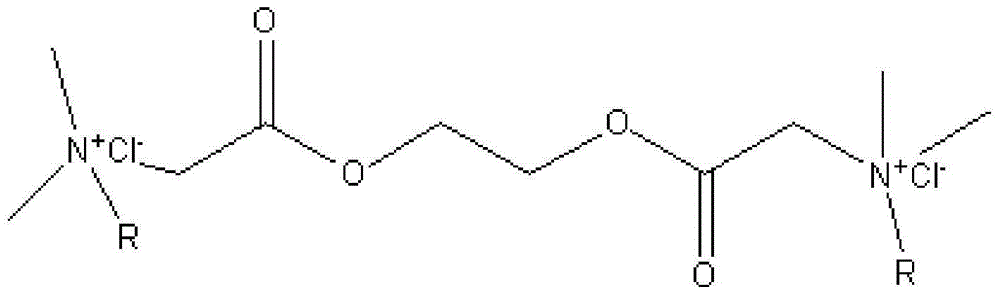

[0030] 1) Add 100mL of deionized water to a 250mL three-necked flask, then add 3.00g of montmorillonite powder, stir well to obtain a dispersion with a concentration of 30g / L, and calculate according to the ion exchange capacity (CEC) of 90mmol / 100g of montmorillonite , add C16 diester-based quaternary ammonium salt surfactant, gradually increase the temperature and stabilize at 70°C, fully stir and condense and reflux for 2 hours to obtain a uniform white suspension;

[0031] 2) Ultrasonic disperse the above white suspension for 15min, then centrifuge at 10000r / min for 20min, remove the supernatant to obtain a white precipitate, wash the white precipitate twice with deionized water and ethanol respectively, and then incubate at 80°C Dry it under vacuum for 24 hours to obtain a white flaky solid, and then grind it to obtain the este...

Embodiment 2

[0034] The preparation method step of present embodiment containing ester group quaternary ammonium salt modified montmorillonite is as follows:

[0035] 1) Add 100mL of deionized water to a 250mL three-neck flask, then add 4.00g of montmorillonite powder, stir well to obtain a dispersion with a concentration of 40g / L, and calculate the ion exchange capacity (CEC) as 90mmol / 100g of montmorillonite , add C16 diester-based quaternary ammonium salt surfactant, gradually increase the temperature and stabilize it at 75°C, fully stir and condense and reflux for 3 hours to obtain a uniform white suspension;

[0036] 2) Ultrasonic disperse the above white suspension for 20min, then centrifuge at 11000r / min for 20min, remove the supernatant to obtain a white precipitate, wash the white precipitate twice with deionized water and ethanol respectively, and then incubate at 80°C Dry it under vacuum for 24 hours to obtain a white flaky solid, and then grind it to obtain the ester group-cont...

Embodiment 3

[0038] The preparation method step of present embodiment containing ester group quaternary ammonium salt modified montmorillonite is as follows:

[0039] 1) Add 100mL of deionized water to a 250mL three-neck flask, then add 6.00g of montmorillonite powder, stir well to obtain a dispersion with a concentration of 60g / L, and calculate the ion exchange capacity (CEC) as 90mmol / 100g of montmorillonite , add C12 diester-based quaternary ammonium salt surfactant, gradually increase the temperature and stabilize it at 80°C, fully stir and condense and reflux for 3 hours to obtain a uniform white suspension;

[0040] 2) Ultrasonic disperse the above white suspension for 25min, then centrifuge at 11000r / min for 20min, remove the supernatant to obtain a white precipitate, wash the white precipitate with deionized water and ethanol three times respectively, and then incubate at 80°C Dry it under vacuum for 24 hours to obtain a white flaky solid, and then grind it to obtain the ester grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com