Light diffusion master batch and preparation method thereof

A technology of light diffusing masterbatch and light diffusing agent, applied in the field of functional masterbatch, can solve the problems of easy scattering and uneven dispersion of light diffusing agent, and achieve the effect of avoiding powder scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

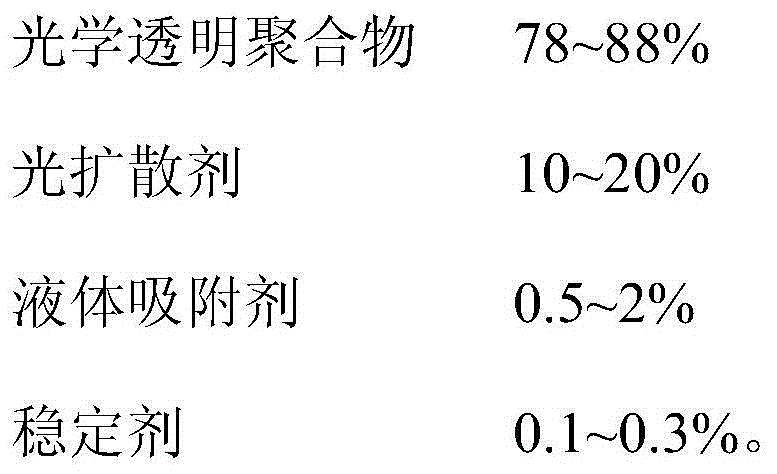

[0034] A light-diffusing masterbatch, which is mainly prepared from the following raw materials according to the mass percentage of each component:

[0035]

[0036] The optically transparent polymer is GPPS, the light diffusing agent is glass microspheres, and the liquid adsorbent is white oil.

[0037] The preparation method of light diffusion masterbatch as above, described method comprises the following steps:

[0038] (1) Pour the light diffusing agent of the formula into the liquid adsorbent, and stir while pouring. In this step, the light diffusing agent is first dispersed into the liquid adsorbent, so that the surface of the light diffusing agent is covered with the liquid adsorbent , to ensure that the light diffusing agent is not easy to drift in subsequent operations;

[0039] (2) Add the optically transparent polymer and stabilizer to the light diffusing agent system obtained in step (1), and stir evenly. Since the surface of the light diffusing agent has been ...

Embodiment 2

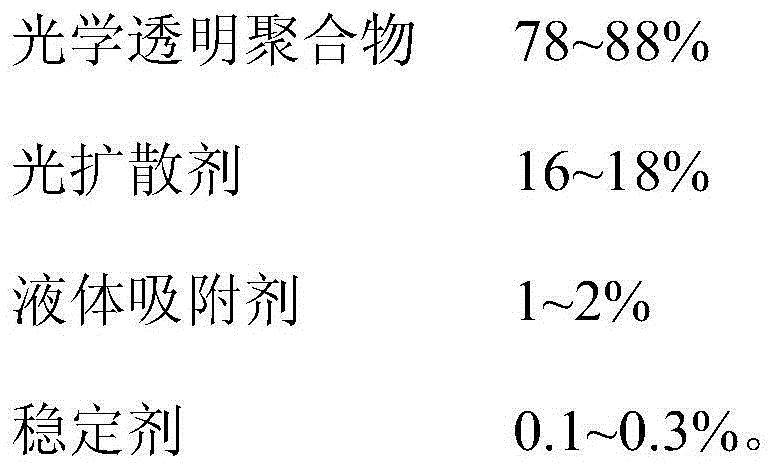

[0043] A light-diffusing masterbatch, which is mainly prepared from the following raw materials according to the mass percentage of each component:

[0044]

[0045]

[0046] The optically transparent polymer is PC, the light diffusing agent is glass microspheres, and the liquid adsorbent is white oil.

[0047] The preparation method of light diffusion masterbatch as above, described method comprises the following steps:

[0048] (1) Pour the light diffusing agent of the formula into the liquid adsorbent, and stir while pouring. In this step, the light diffusing agent is first dispersed into the liquid adsorbent, so that the surface of the light diffusing agent is covered with the liquid adsorbent , to ensure that the light diffusing agent is not easy to drift in subsequent operations;

[0049] (2) Add the optically transparent polymer and stabilizer to the light diffusing agent system obtained in step (1), and stir evenly. Since the surface of the light diffusing agent...

Embodiment 3

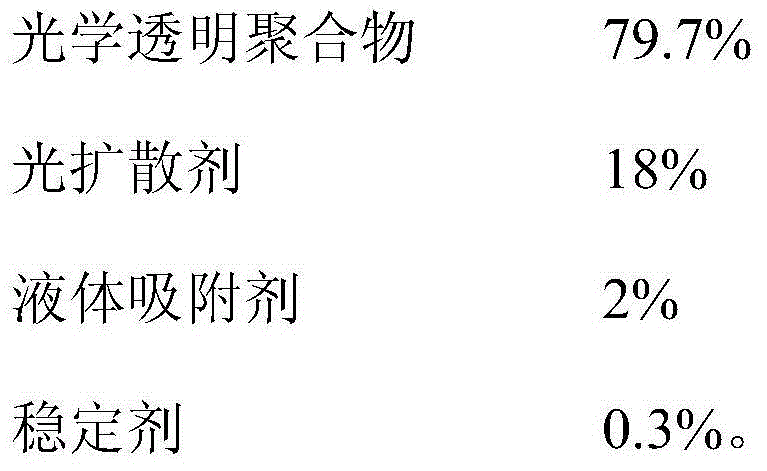

[0053] A light-diffusing masterbatch, which is mainly prepared from the following raw materials according to the mass percentage of each component:

[0054]

[0055] The optically transparent polymer is PC, the light diffusing agent is glass microspheres, and the liquid adsorbent is silicone oil.

[0056] The preparation method of light diffusion masterbatch as above, described method comprises the following steps:

[0057] (1) Pour the light diffusing agent of the formula into the liquid adsorbent, and stir while pouring. In this step, the light diffusing agent is first dispersed into the liquid adsorbent, so that the surface of the light diffusing agent is covered with the liquid adsorbent , to ensure that the light diffusing agent is not easy to drift in subsequent operations;

[0058] (2) Add the optically transparent polymer and stabilizer to the light diffusing agent system obtained in step (1), and stir evenly. Since the surface of the light diffusing agent has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com