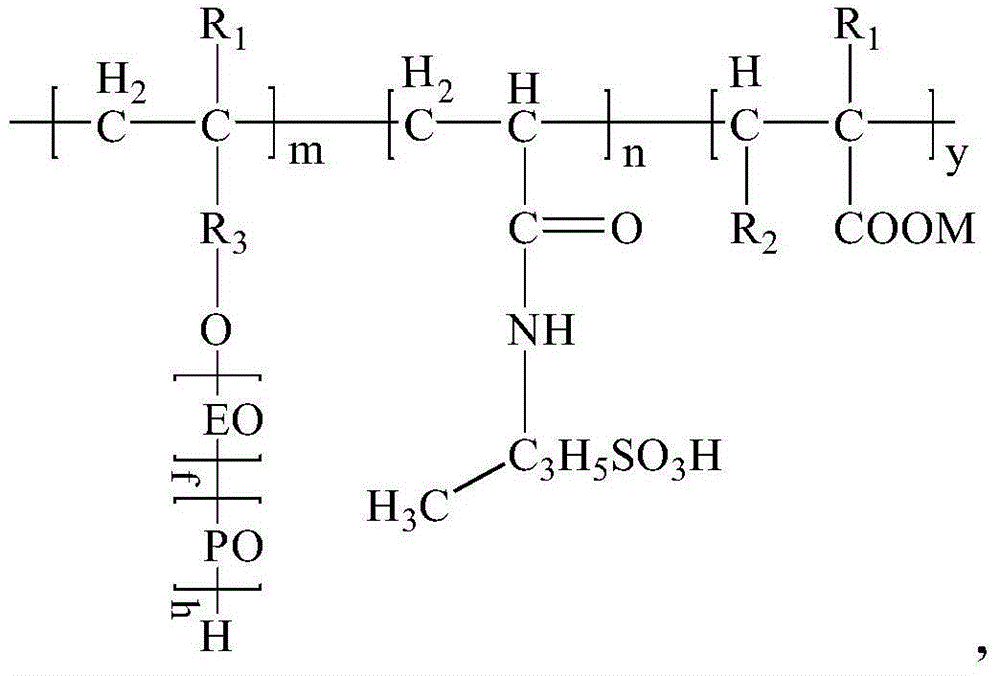

Polycarboxylate superplasticizer with mud preventing effect and preparation method of polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, applied in the field of chemical building materials construction, can solve problems such as difficulty in meeting actual needs, unstable mother liquor quality, easy crystallization and precipitation, etc. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

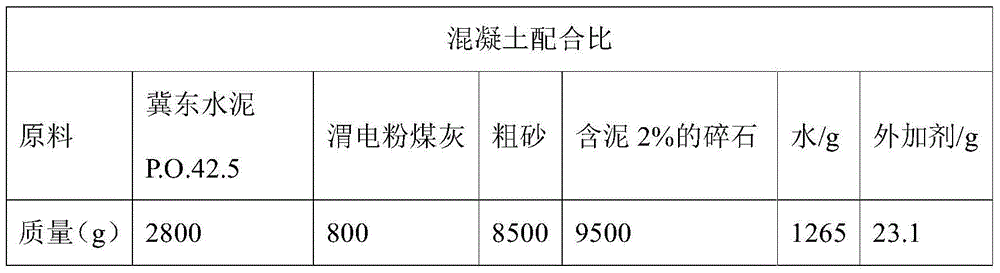

Embodiment 1

[0027] Polymerization reaction: Add 280.00g of water and 180.00g of methallyl polyoxyethylene polyoxypropylene ether (average molecular weight: 2400) to the flask and raise the temperature to 40-50°C. After stirring and dissolving, add 2.80g of hydrogen peroxide solution respectively, Mixed solution of acrylic acid and AMPS (50.00g of mixture, 20.00g of acrylic acid, 6.00g of AMPS), 3-isooctyl mercaptopropionate + vitamin C solution (1.90g of isooctyl mercaptopropionate, 0.48g of vitamin C, water 40.00g), potassium hypophosphite solution (0.26g potassium hypophosphite, 20.00g water), maintain the temperature at 40-50°C, add dropwise for 3.0 hours, and continue stirring for 1.0 hour to obtain a colorless transparent solution.

[0028] Neutralization reaction: Add sodium hydroxide solution to adjust the pH to neutral to obtain a polycarboxylate superplasticizer with mud-repelling effect.

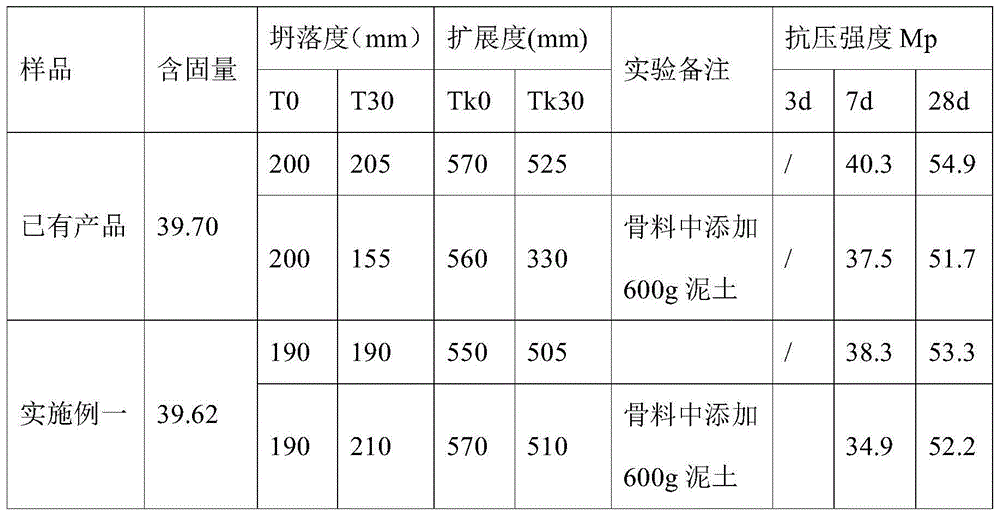

[0029] The polycarboxylate superplasticizer with mud-blocking effect prepared in Example 1...

Embodiment 2

[0037] Polymerization reaction: Add 286.00g of water, 7.20g of AMPS and 180.00g of isopentenol polyoxyethylene polyoxypropylene ether (average molecular weight: 2400) into the flask, heat up to 35-43°C and stir to dissolve, then add 2.00g of hydrogen peroxide solution , mixed solution of acrylic acid (isooctyl thioglycolate 1.80g, acrylic acid 19.00g, water 25.00g), potassium hypophosphite solution (potassium hypophosphite 0.26g, water 20.00g), maintain the temperature at 35-43°C, add dropwise for 2.5 hours , and continue stirring for 1.0 hour to obtain a colorless transparent solution

[0038] Neutralization reaction: Add potassium hydroxide solution to adjust the pH to neutral to obtain a polycarboxylate superplasticizer with mud-repelling effect.

Embodiment 3

[0040] Polymerization: Add 240.00g of water, 3.60g of AMPS and 180.00g of isopentenol polyoxyethylene polyoxypropylene ether (average molecular weight: 2400) to the flask, heat up to 45-55°C and stir to dissolve, then add 2.50g of hydrogen peroxide solution, Acrylic acid mixed solution (isooctyl mercaptopropionate 1.90g, acrylic acid 21.60g, water 22.00g), potassium hypophosphite solution (potassium hypophosphite 0.20g, water 25.00g), maintain temperature at 45-55°C, add dropwise for 2.5 hours , and continue to stir for 0.5 hours to obtain a colorless transparent solution

[0041] Neutralization reaction: Add potassium hydroxide solution to adjust the pH to neutral to obtain a polycarboxylate superplasticizer with mud-repelling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com