Sub-frame of multi-link suspension system

A suspension system and sub-frame technology, which is applied in the field of auto parts, can solve the problems that affect the stability and comfort of the whole vehicle, the welding heat of the sub-frame is large, and the suspension hard point error is large, so as to achieve good product consistency. , welding heat is small, the effect of short weld length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

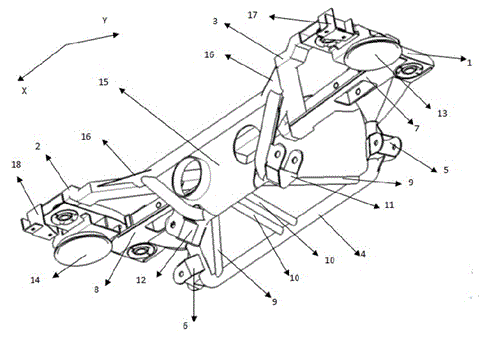

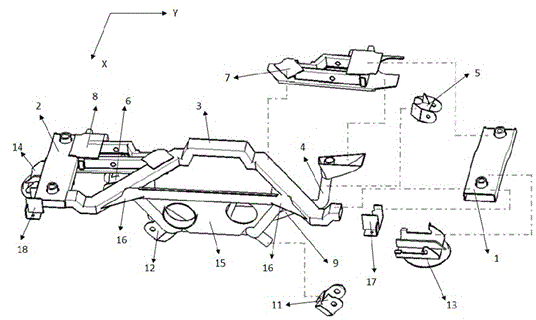

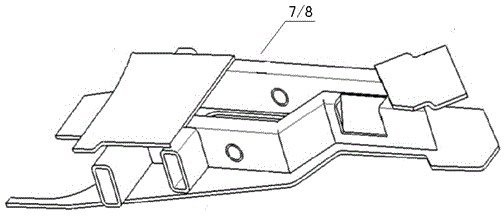

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] see figure 1 , figure 2 , image 3 with Figure 4 The subframe of a multi-link suspension system shown includes a "V"-shaped upper beam 3, a right longitudinal beam 1 connected to the right end of the upper beam at one end of one side, and a The left longitudinal beam 2 connected with the left end of the upper beam; also includes a first right mounting bracket 5, one end of the first right mounting bracket is connected with the other end of one side of the right longitudinal beam 1, the The other end of the first right mounting bracket is connected to the right part of the upper beam 3; it also includes a first left mounting bracket 6, one end of the first left mounting bracket is connected to the other end of one side of the left longitudinal beam 2 Connection, the other end of the first left mounting bracket is connected to the left part of the upper bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com