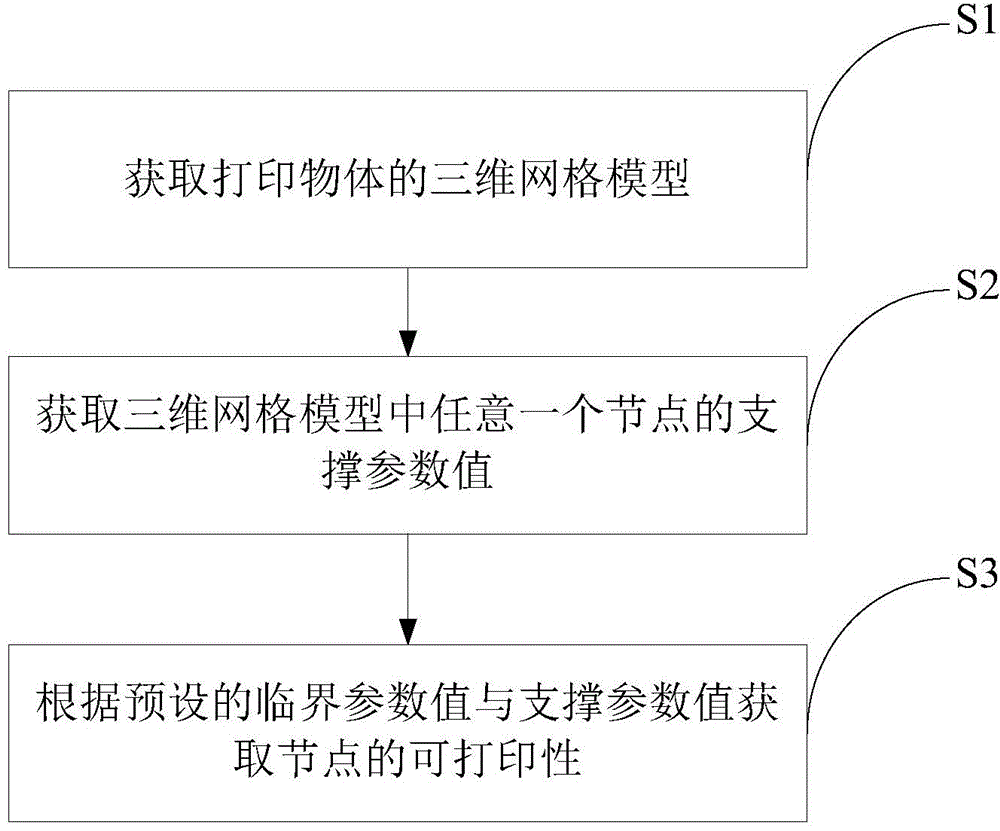

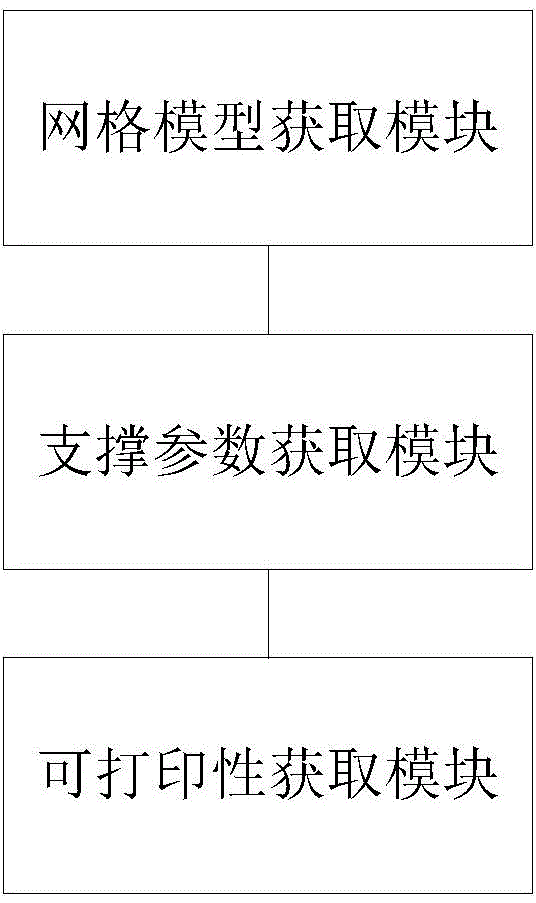

Printability acquisition method and system for three-dimensional printing

A technology of three-dimensional printing and acquisition method, applied in the field of three-dimensional printing, can solve the problems of unprintable, sticky material, unable to support and print the model normally, and achieve the effect of accurate acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

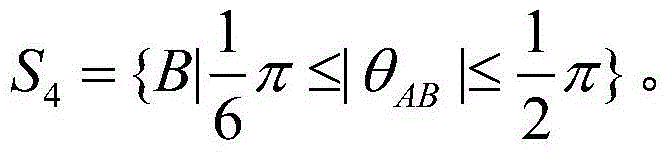

[0044] In the process of 3D printing, since 3D printing is printed layer by layer from bottom to top, for a newly printed layer, it will be supported by the layer below it. When the 3D printer prints to a certain point, if there is a printed solid point directly below the point, then the point can be supported by the solid point directly below and can be successfully printed; if the point directly below If there is no solid point, but there is a solid point obliquely below the point, whether the point can be supported by the solid point obliquely below depends on the viscous characteristics of the printing material and the tilt parameters.

[0045]According to the above-mentioned working principle of 3D printing, in the process of realizing the application, by assigning a support parameter to each node on the 3D mesh model of the object to measure the support stability of the node, the support of the node on the 3D mesh model The parameter value is generated by passing the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com