A kind of coal preparation collector and preparation method thereof

A technology for collectors and coal preparation, applied in flotation, solid separation and other directions, can solve the problems of not being reasonably recovered and utilized, the recycling value of by-products is not high, and the economic benefits are poor, so as to achieve efficient recovery and utilization. Problems, good collection and foaming ability, effect of development promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

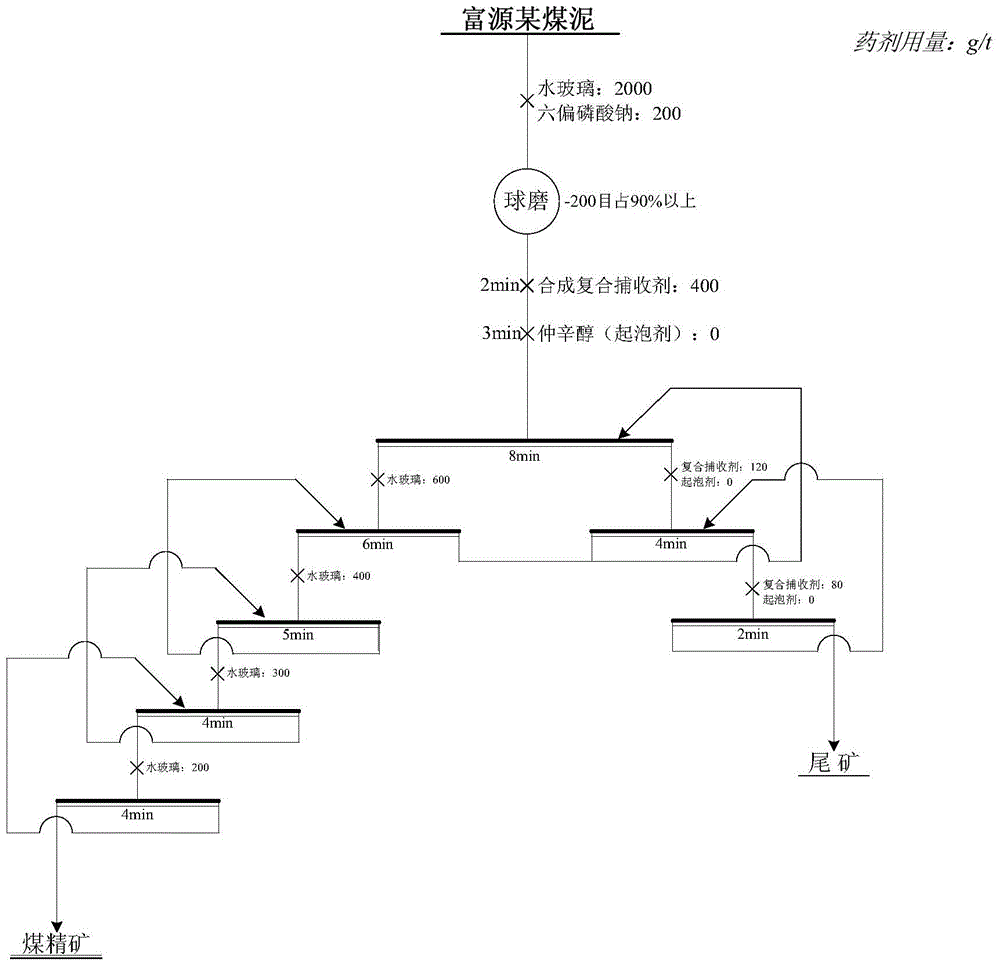

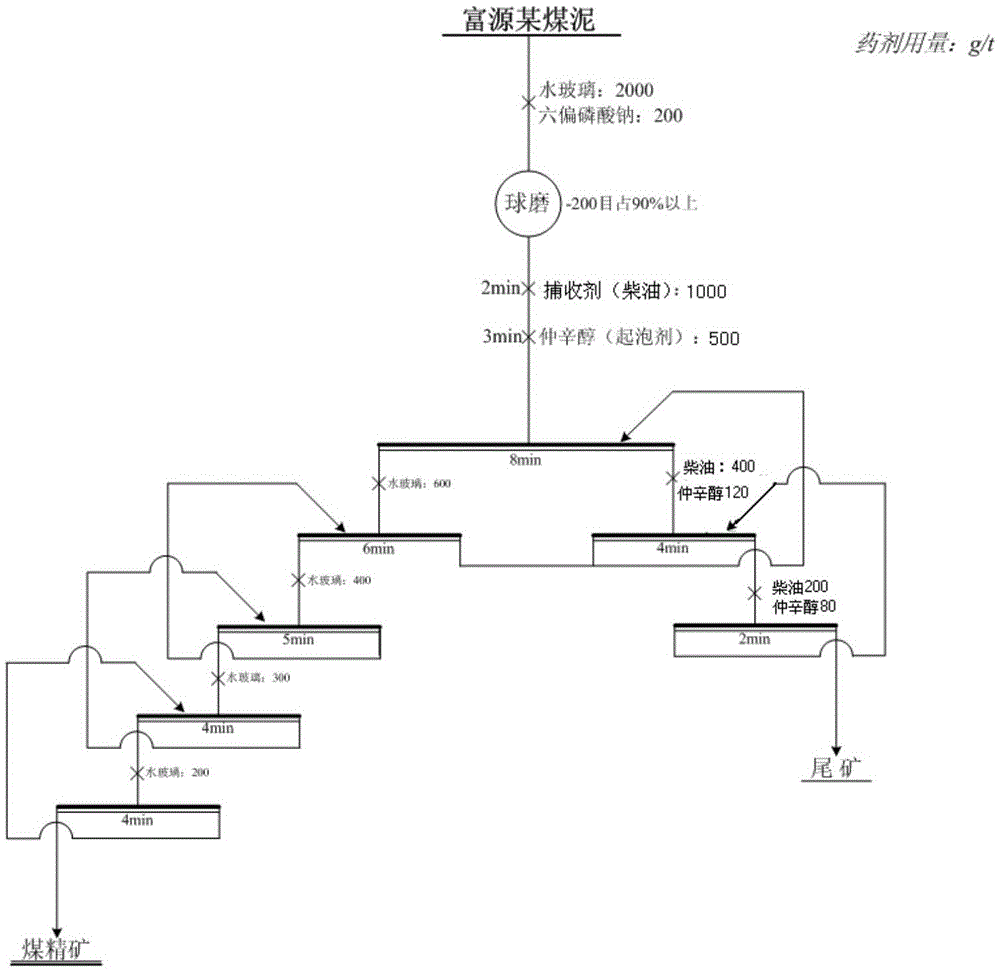

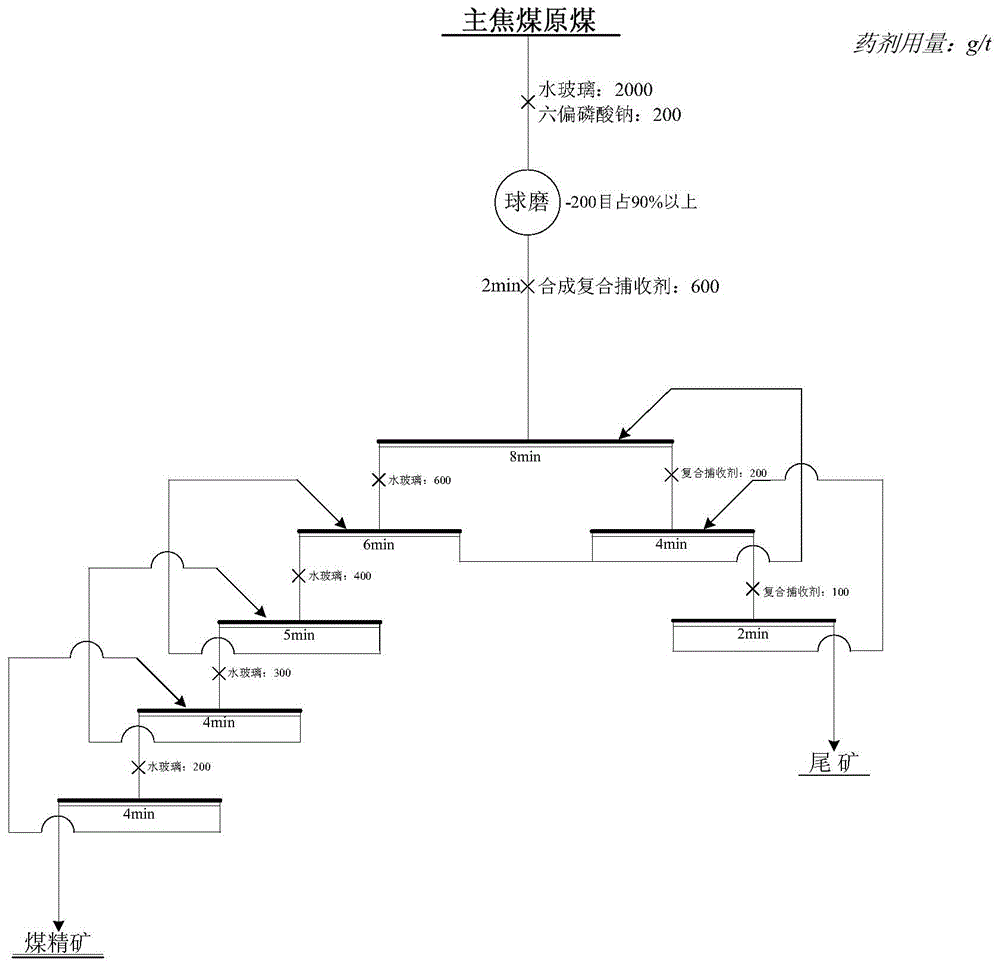

Image

Examples

Embodiment 1

[0042] Add 100 parts of butanol raffinate (parts by mass, the same below), 20 parts of phthalic anhydride, and 0.5 parts of concentrated sulfuric acid (catalyst) into the reactor with reflux and stirring, and start stirring; first, the temperature is raised to 105°C Under the esterification reaction for 2 hours, then continue to heat up to 240 ° C for 4 hours, so that the fatty alcohol in the butanol raffinate and phthalic anhydride fully react to form a mixed ester of phthalic acid; the esterification reaction ends Finally, the product is cooled, left to stand for layering, and the water is separated, and the target product is left in the organic phase; 3 parts of anhydrous sodium sulfate (solid desiccant) are added to the organic phase, stirred to make it fully absorb the residual moisture in the organic phase, and then Separate the bottom solid (sodium sulfate containing crystal water), and the obtained organic phase product is the synthesized composite coal preparation coll...

Embodiment 2

[0049] Add 100 parts of butanol raffinate (refer to the mass, the same below), 70 parts of phthalic anhydride, and 0.9 parts of antimony trichloride (Lewis solid acid, catalyst) into the reactor with reflux and stirring, and start stirring; First, the temperature is raised to 95°C for 3 hours of esterification reaction, and then the temperature is continued to be raised to 250°C for 3 hours of esterification reaction, so that the fatty alcohol in the butanol raffinate and phthalic anhydride fully react to form a phthalic acid mixed ester ; After the esterification reaction is finished, the product is cooled, left to stand for layering, and the water is separated, and the target product is left in the organic phase; 8 parts of anhydrous magnesium sulfate (solid desiccant) are added to the organic phase, and stirred to make it fully absorbed in the organic phase. The residual moisture, and then separate the bottom solid (magnesium sulfate containing crystal water), and the upper ...

Embodiment 3

[0052] Add 100 parts of butanol raffinate (referring to the mass, the same below), 50 parts of phthalic anhydride, and 0.5 parts of p-toluenesulfonic acid (Lewis solid acid, catalyst) into the reaction kettle with reflux and stirring, and start Stir; first raise the temperature to 110°C for 2 hours of esterification reaction, then continue to raise the temperature to 220°C for 4 hours of esterification reaction; after the esterification reaction is completed, cool the product, let it stand and separate the water, and the target product remains in the organic phase Add 2 parts of molecular sieves (solid desiccant) to the organic phase, stir to make it fully absorb the residual moisture in the organic phase, then separate the bottom solid (molecular sieve with water), and the upper organic phase is the composite collector product of synthesis.

[0053] Using the above-mentioned synthetic products as collectors, the test of flotation and recovery of carbon from steel plant soot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com